7.3 Setting the Measuring Unit, Probe and Resolution ............................15

7.4 Min Capture ........................................................................................16

7.5 2-Point Calibration ............................................................................. 17

7.6 Brightness Setting ...............................................................................19

7.7 Limits Setting ..................................................................................... 20

7.8 Backlight Function ............................................................................. 21

7.9 Low Voltage Warning Function ..........................................................21

7.10 Ways of Turning Off ......................................................................... 21

8. Measurement Application .............................................................................21

8.1 The Condition Requirements on the Surface of the Work-piece ....... 21

8.1.1 Clean Surface ...........................................................................21

8.1.2 Enhancing the Roughness Requirement ..................................22

8.1.3 Surface of the Rough Machine Processing ............................. 22

8.2 Measuring Methods ............................................................................ 22

8.2.1 Single-Point Measurement ...................................................... 22

8.2.2 Double-Point Measurement .....................................................23

8.2.3 Multiple-Point Measurement ...................................................23

8.2.4 Continuous Measurement ........................................................23

8.3 Pipe Walls Measurement .................................................................... 23

8.4 Cast Measurement .............................................................................. 24

9. Maintenances and Cautions ..........................................................................24

9.1 Power Source Inspection .................................................................... 24

9.2 Cautions .............................................................................................. 25

9 . 2 . 1 G e n e r a l C a u t i o n s ..........................................................25

9.2.2 Measuring Cautions ..........................................................25

9.2.3 Changing the Prob e ..........................................................25

9.3 Maintenances ...................................................................................... 26

10. After-Sale Services ..................................................................................... 26

Appendix A: Sound Velocities of Some Common Materials………...............27

Appendix B: Probe and Measuring Range…………………………...............28

1.General Information of The Gauge

UM series ultrasonic thickness gauge made by our factory is a simple-to-use,

highly accurate, hand-held ultrasonic thickness gauge with the operating

principle of ultrasonic wave measuring. It can measure quickly,

nondestructively and precisely with a resolution of 0.001in/0.01in or

0.01mm/0.1mm. This instrument can be widely used in the fields such as

manufacturing, metal processing, chemistry and business inspecting for

measuring the thickness of all sorts of materials where ultrasonic wave can

spread through with a constant speed and get the reflection from the back side.

Apart from making accurate measure on various kinds of plates and

processing components, it can also make detection on various kinds of pipes

and pressure containers of the manufacturing facilities about their thickness

loss after corrosion. It’s the necessary specialized instrument for material

protection.

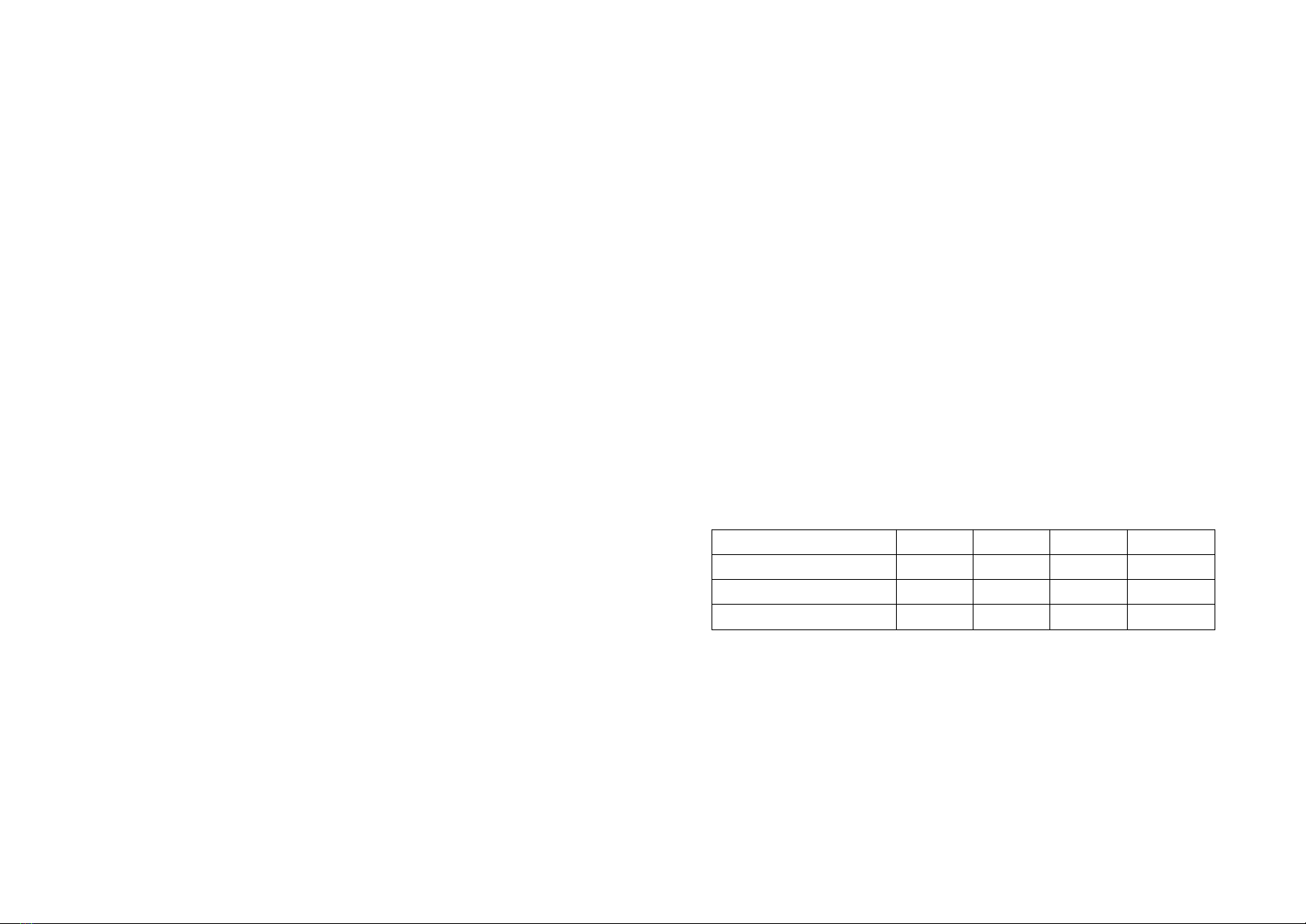

This manual applies to the models of UM-1, UM-1D, UM-2 and UM-2D

ultrasonic thickness gauges, the difference between them in the list below:

Note: The schematic diagram and features in the manual reference to UM-2

model without special mark.

1.1 Measuring Principle

UM series ultrasonic thickness gauge measures the thickness of an object by

precisely calculating the times of the probe sending ultrasonic pulse with the

help of couplant to the object and passing through the object until the probe

receiving the reflection from the boundary.