YZ Systems Milton Roy • 201 Ivyland Road • Ivyland, Pennsylvania • USA • 18974 • P: 281.362.6500 • www.yzsystems.com

DP-2010 ver.05-2018

Page 2

seCTion 1: firsT Things ToKnow abouT The DynaPaK

Operation Specications

Maximum Output: 5,760 cc/day

(5.76 liters/day)

Maximum Operating Pressure: 1,500 psig

(124 Bar (g))

Pump Displacement: .2 - .4 cc/Stroke

Operating Temp Range: 0 to 140 degrees F.

(17˚C to 60˚C)

Power Supply: Internal Battery Pack

Flow Signal: Dry Contact or

Voltage Pulse

Theory of Operation

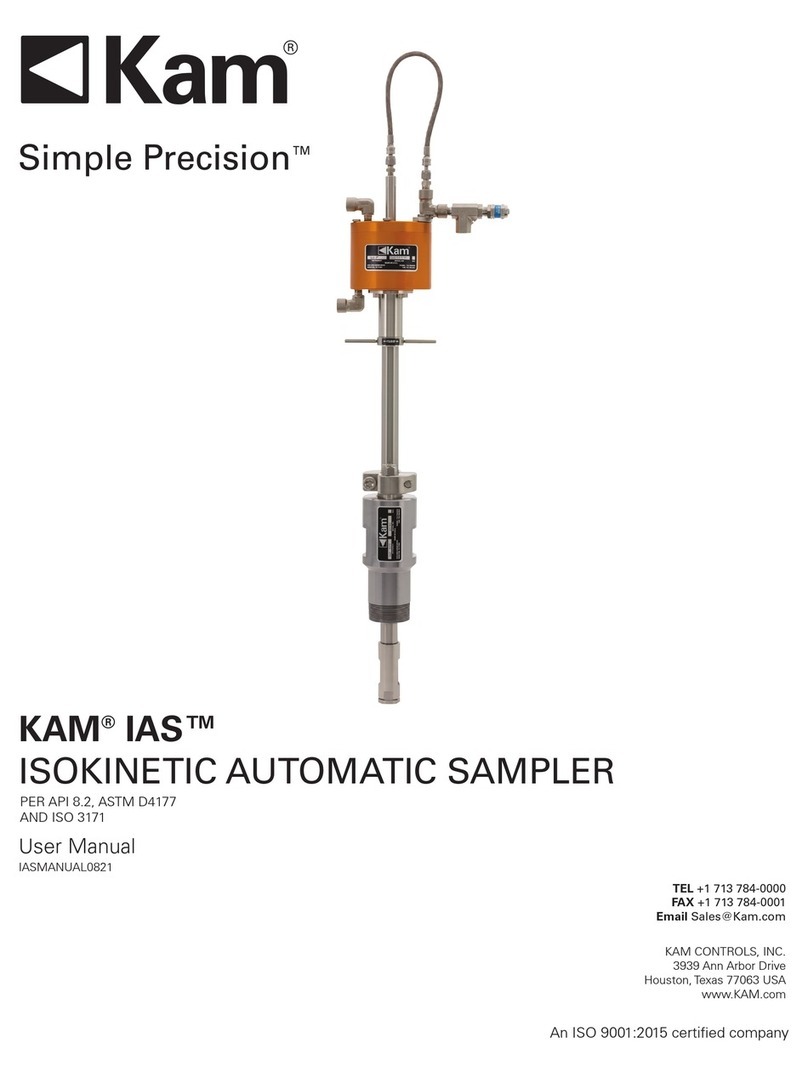

The DynaPak 2010 Sampler is a pipeline

mounted system which uses the pneumatically

operated, positive displacement DynaPak 2000

pump, the Z-65 timer/controller, the YZ lter/reg-

ulator and a low power solenoid valve to obtain

gas samples. The 2010 provides two modes

of operation:

A. Time-based sampling:

In this mode of operation, the 2010 extracts a

gas sample from the pipeline at regular time in-

tervals. The volume of the sample is set by the

operator using the volume adjustment feature of

the DP-2000 pump. The Z-65 controller oper-

ates as a recycling timer, periodically energizing

a low power solenoid valve. Energizing the so-

lenoid valve allows actuation gas to stroke the

DP-2000 pump. The rate at which this occurs

is a function of operator input. Two 10 position

switches are used to set the off time interval.

The number of times the solenoid output is ac-

tivated is recorded by the onboard LCD stroke

indicator.

B. Proportional-to-Flow sampling:

In this mode of operation, the Z-65 counter

operates as a dividing counter. The Z-65 coun-

ter periodically energizes a low power solenoid

valve. As in the time-based mode of operation,

this allows actuation gas to stroke the DP-2000

pump. The rate at which this occurs is a function

of operator input as well as the host computer

or other device that inputs pulses per volume

metered. The two 10-position switches on the

Z-65 are used to set the number of pulses the

counter will count before activating the solenoid

output. The number of times the solenoid output

is activated is recorded by the onboard LCD

stroke indicator. Sample volume is again con-

trolled using the DP-2000 volume adjustment

knob.

In both modes of operation, the Z-65 timer/

counter operates using a replaceable internal

battery pack. The battery pack condition is

monitored by way of two indicator LEDs. When

the battery pack needs replacement, the red

LED will illuminate when the solenoid output is

activated. If the battery pack is good, the green

LED will illuminate when the solenoid is acti-

vated.