RTM-30 TEMPERATURE REGULATOR MANUAL INSTRUCTION

sp.j.

J.W. Dzida, K. Łodzińska

ul. Zielona 27, 43-200 Pszczyna, Poland

Tel. +48 (32) 210 46 65, Fax +48 (32) 210 80 04

RTM-30

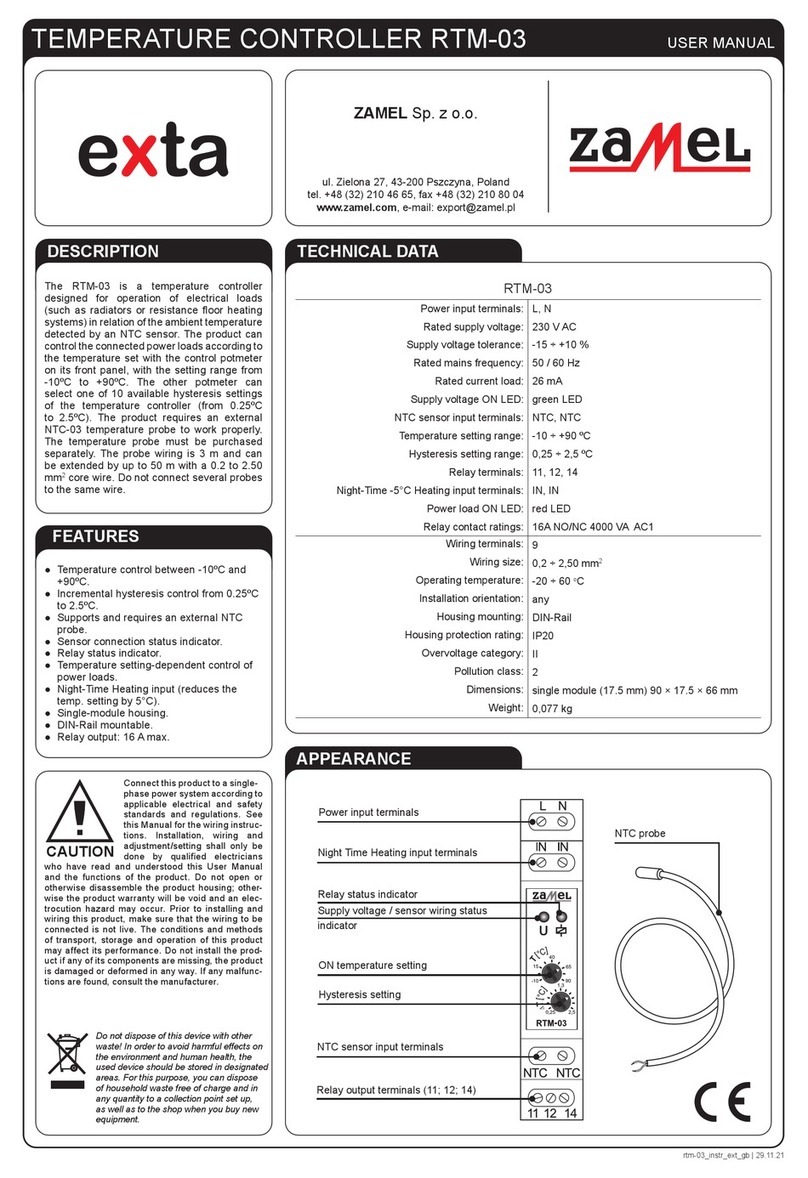

Power supply terminals: A1, A2

Input rated voltage: 85 ÷ 265 V AC

Nominal frequency: 50 / 60 Hz

Rated power consumption: < 1,5 W

Temperature sensor terminals: T1 (t reference), T2 (t expected)

Temperature sensor type: KTY 81-210

Temperature regulation adjustment range: 5 ÷ 95 oC

Hysteresis: +/- 0,5 oC

Relay output (supply) terminals: 11, 12, 14, 21, 22, 24

Receiver switch on indicator: LCD

LCD display backlight: amber

Output relay parameters: 2NO/NC 16A / 250V AC1 4000VA

Number of terminal clamps: 12

Section of connecting cables: 0,2 ÷ 2,50 mm2

Regulator ambient temperature range: -20 ÷ 60 oC

Sensor ambient temperature range: -20 ÷ 90 oC

Operating mode: freely

Mounting: rail TH35 (acc to PN-EN 60715)

Protection degree: IP20 (PN-EN 60529)

Protection level: II

Overvoltage category: II

Pollution degree: 2

Dimensions: double-modular (35 mm) 90x35x66 mm

Weight: 0,160 kg

Reference standards: PN-EN 60730-1; PN-EN 60730-2-7

PN-EN 61000-4-2,3,4,5,6,11

● Temperature level regulation in the range

of 5 ÷ 95 °C,

● two external temperature sensors,

● LCD display and keypad,

● output receiver’s temperature regulation in

accordance with the reference temperatu-

re,

● output receiver’s temperature regulation in

accordance with temperature differences,

● heating sources economical regulation

gives enormous savings during heating

period,

● simultaneous regulation possibilities of

cooling and heating sources,

● temperature regulation possibility by

means of blending valves,

● replacing possibility of a reference tempe-

rature regulator with a standard resistor,

● double-modular casing with a shield,

● TH-35 DIN rail installation,

● two output relays of max 16A capacity.

The temperature regulator operation is

based on heating/regulation curve which we

obtain by means of choosing points inclu-

ding both the expected temperature and the

reference temperature, by choosing a ready

made curve or by changing options for room

regulation. The regulator preserves the tem-

perature with the heating source suitable for

the reference point (e.g outer or inner tem-

perature), chosen during conguration pha-

se. Regulation algorithm causes the heating

costs lower and the same gives full comfort of

room and weather regulation. The regulator

uses two sensors for proper operation. There

is also a possibility of extending its existing

connection cable up to 50 m with a cable sec-

tion of 0,2÷2,5 mm

2

. The reference tempera-

ture sensor can be replaced with a standard

resistor, which causes one sensor operation

as in the standard temperature regulation.

The regulator is a perfect solution in eve-

ry situation we want to be sure there was a

full factor ciculation e.g.: cooling systems or

heating systems, but also in situations where

suitable temperature difference is necessary

for preserving best conditions with maximum

low costs e.g.: hot water circulation. Repla-

cing one temperature sensor with a standard

resistor has the effect of constant regulation

around one point in accordance with the ad-

justed curve, close to the chosen points.

Replacing one temperature sensor with a

potentiometer with similar functions has the

effect of changing a universal regulator into a

standard temperature regulator with differen-

ce regulation possibility by means of curve

and hysterisis. It allows to control, e.g., the

heating source in such a way its temperature

is higher than the adjusted one including dif-

ference corresponding e.g. the ambient tem-

perature loss through windows, etc.

VER. 002_20.05.2010

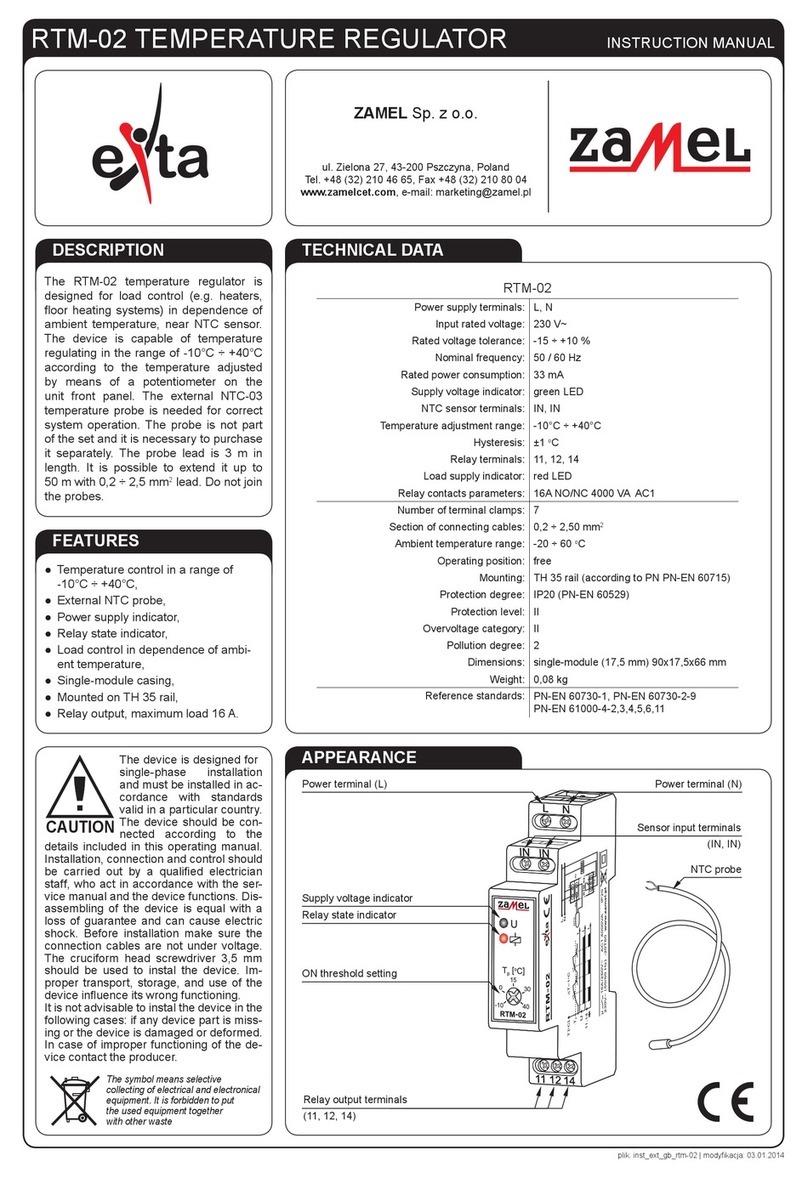

LCD display

Control pushbuttons

Temperature sensor clamps

(T1, T2)

Power supply

terminals (A1, A2)

Relay output (supply) terminals

(12, 11, 14, 24, 21, 22)

The symbol stands for selective

collection of electrical and

electronical devices. It is

forbidden to place the used

devices with other waste.

RTM-30 temperature regulator belongs

to RTM family product.

1. Disconnect power supply by the pha-

se fuse, the circuit-breaker or the

switch- disconnector combined to the

proper circuit.

2. Check if there is no voltage on con-

nection cables by means of a special

measure equipment.

3. Install the RTM-30 on the TH-35 DIN

rail in the switchboard.

4. Connect the cables with the termi-

nals in accordance with the installing

diagram.

5. Switch on the power supply from the

mains.

Outer temperature sensor

RTM-30 regulator

Room temperature sensor

Floor heating

Air-conditioner

L

N

Heating

Cooling

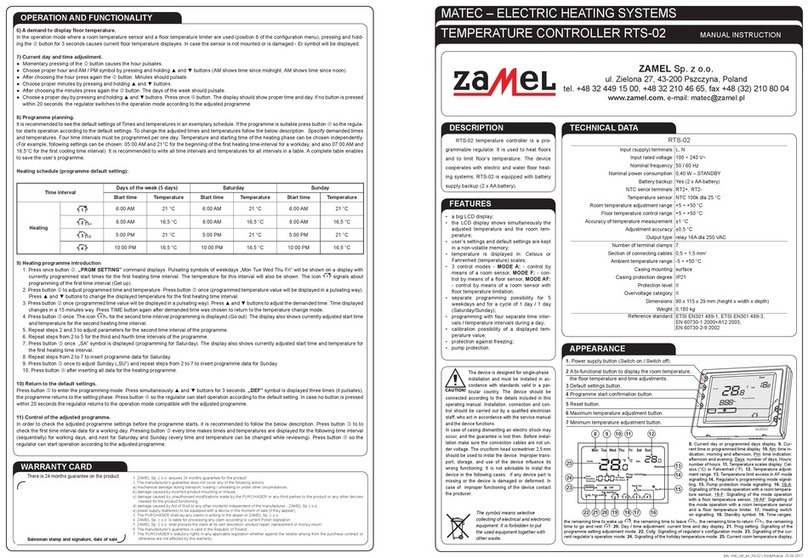

Device type:

01 - basic

02 - LCD display

03 - weather with LCD

display

Device symbol

xx

L

N

μC

KLAW.

LCD

ZAS. A/C A/C

RTC

There is 24 months guarantee on the product

1. ZMIE ZAMEL SP. J. assures 24 months guarantee for the product.

2. The manufacturer’s guarantee does not cover any of the following actions:

a) mechanical damage during transport, loading / unloading or under other circumstances,

b) damage caused by incorrect product mounting or misuse,

c) damage caused by unauthorised modications made by the PURCHASER or any third parties to the product or any other devices

needed for the product functioning,

d) damage caused by Act of God or any other incidents independent of the manufacturer.

3. The PURCHASER shall lay any claims in writing to the dealer or ZMIE ZAMEL SP. J.

4. ZMIE ZAMEL SP. J. is liable for processing any claim according to current Polish legislation.

5. ZMIE ZAMEL SP. J. shall process the claim at its own discretion: product repair, replacement or money return.

6. The manufacturer’s guarantee is valid in the Republic of Poland.

7. The PURCHASER’s statutory rights in any applicable legislation whether against the retailer arising from the purchase contract or

otherwise are not affected by this warranty.