3

Contents

1 General information ......................................................................... 4

1.1 Introduction .....................................................................................4

1.2 Manufacturer ...................................................................................4

1.3 Type approval....................................................................................4

1.4 Warranty ..........................................................................................4

1.5 Date of issue.....................................................................................5

1.6 Copyright and trademark rights ......................................................5

1.7 Intended use ....................................................................................5

1.8 Improper use ....................................................................................5

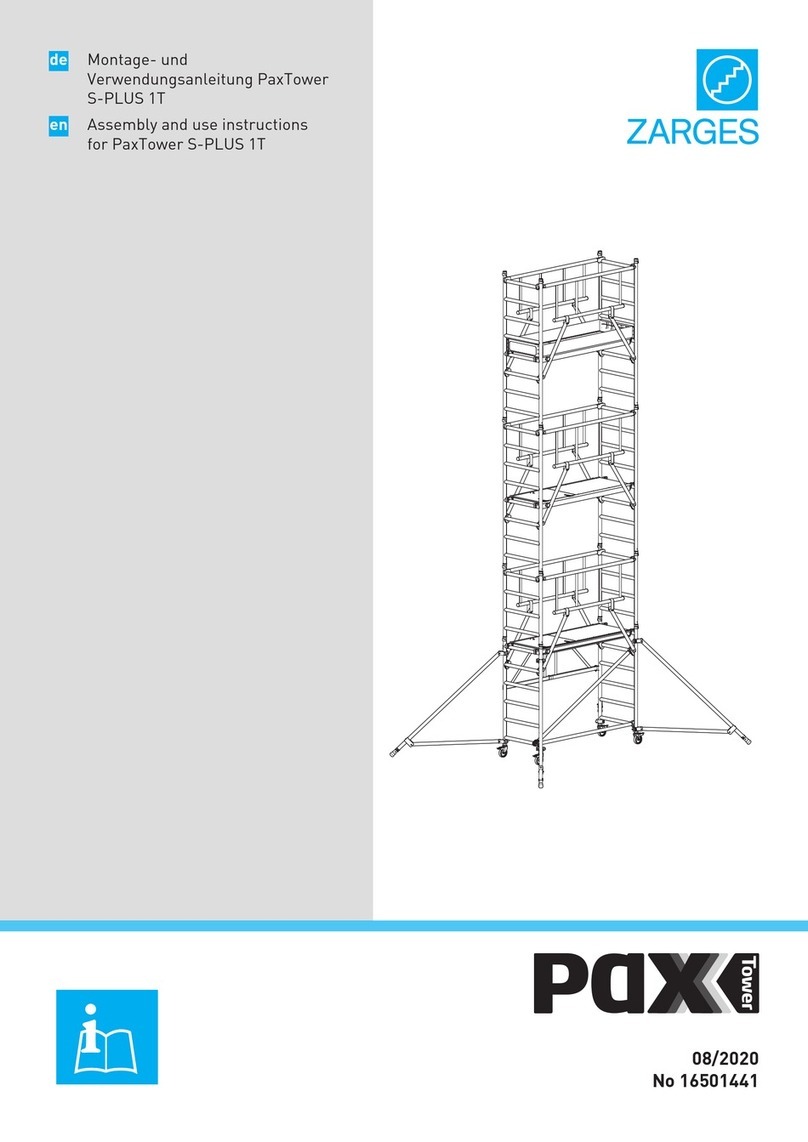

2 Assembly ......................................................................................... 6

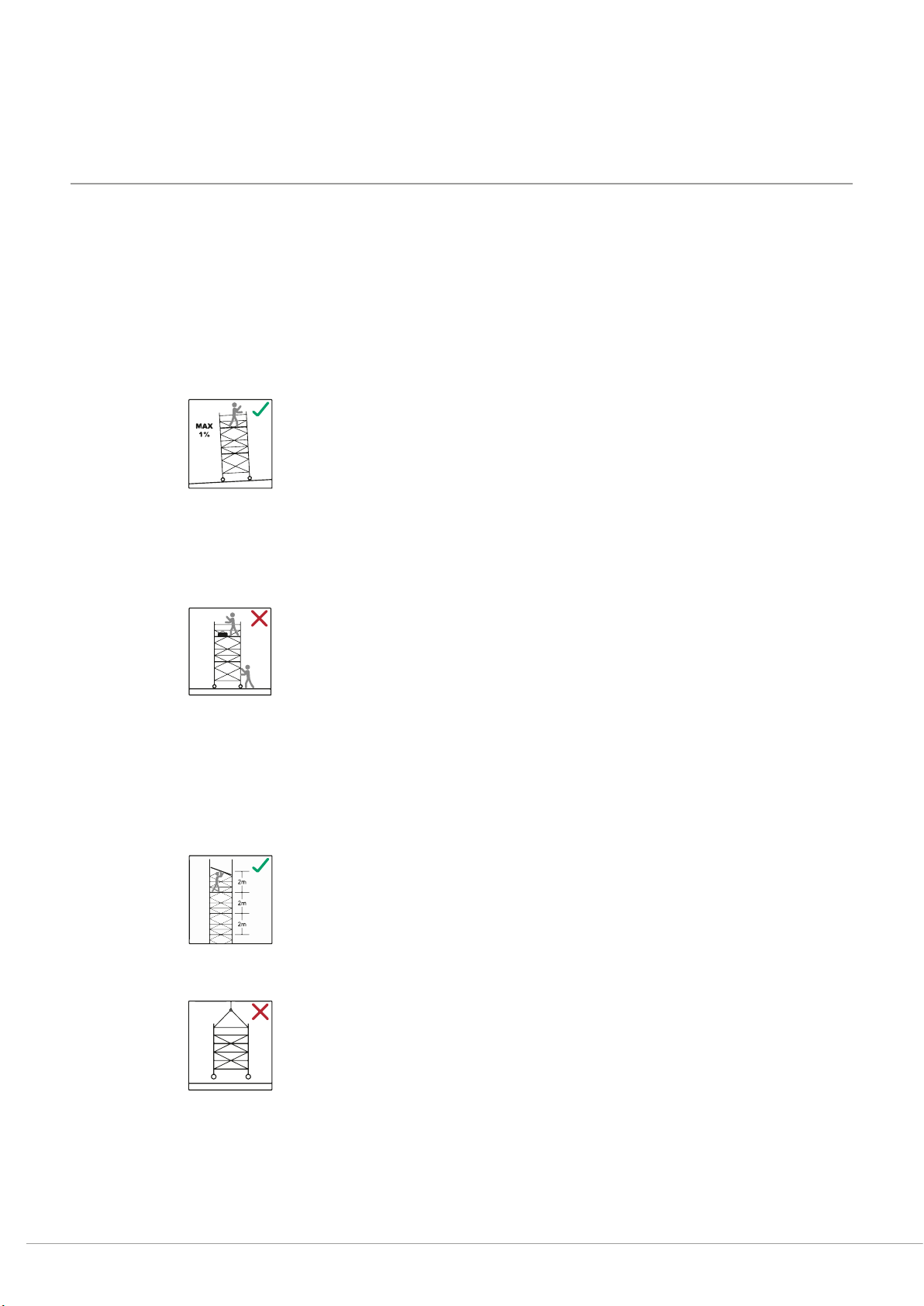

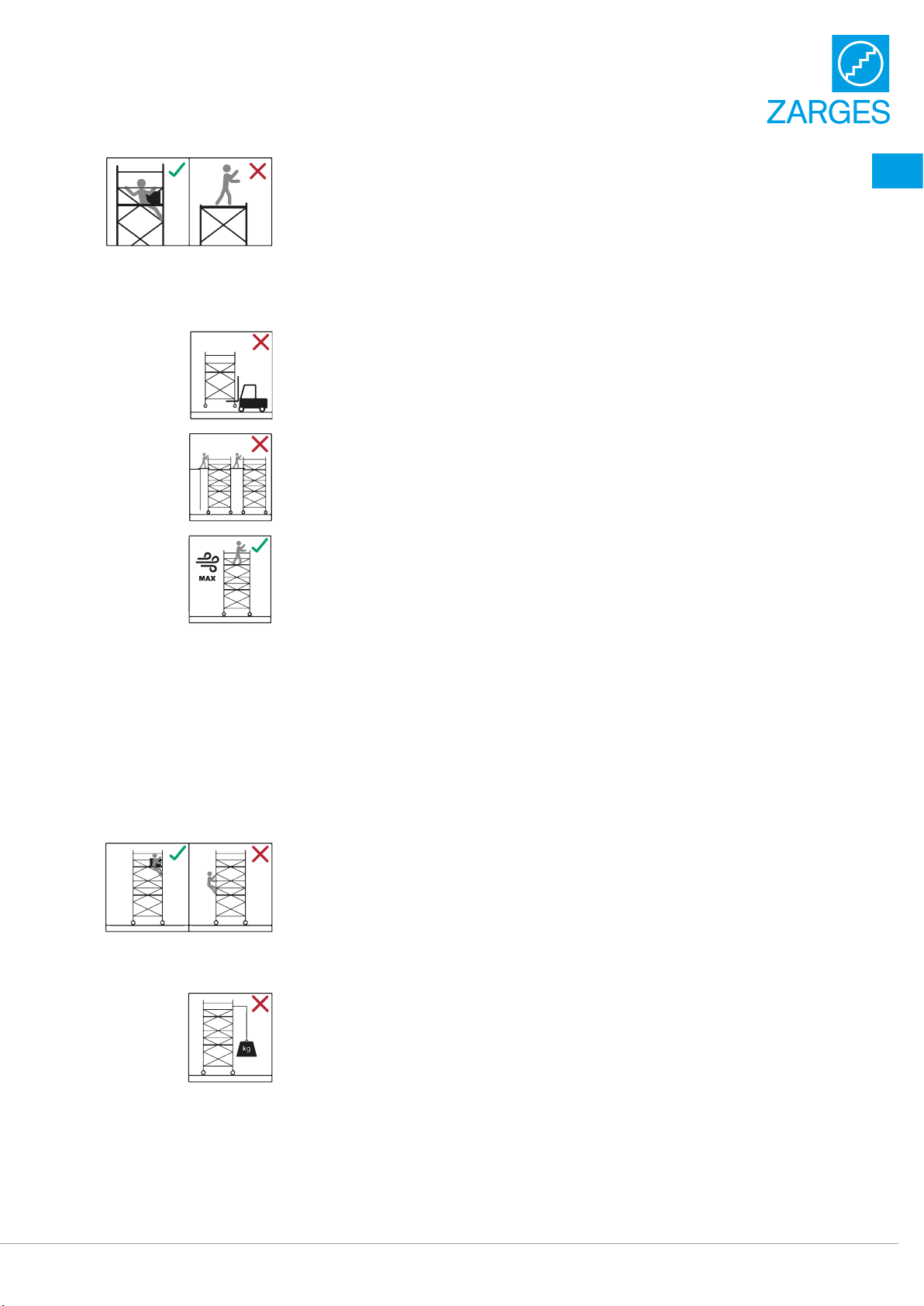

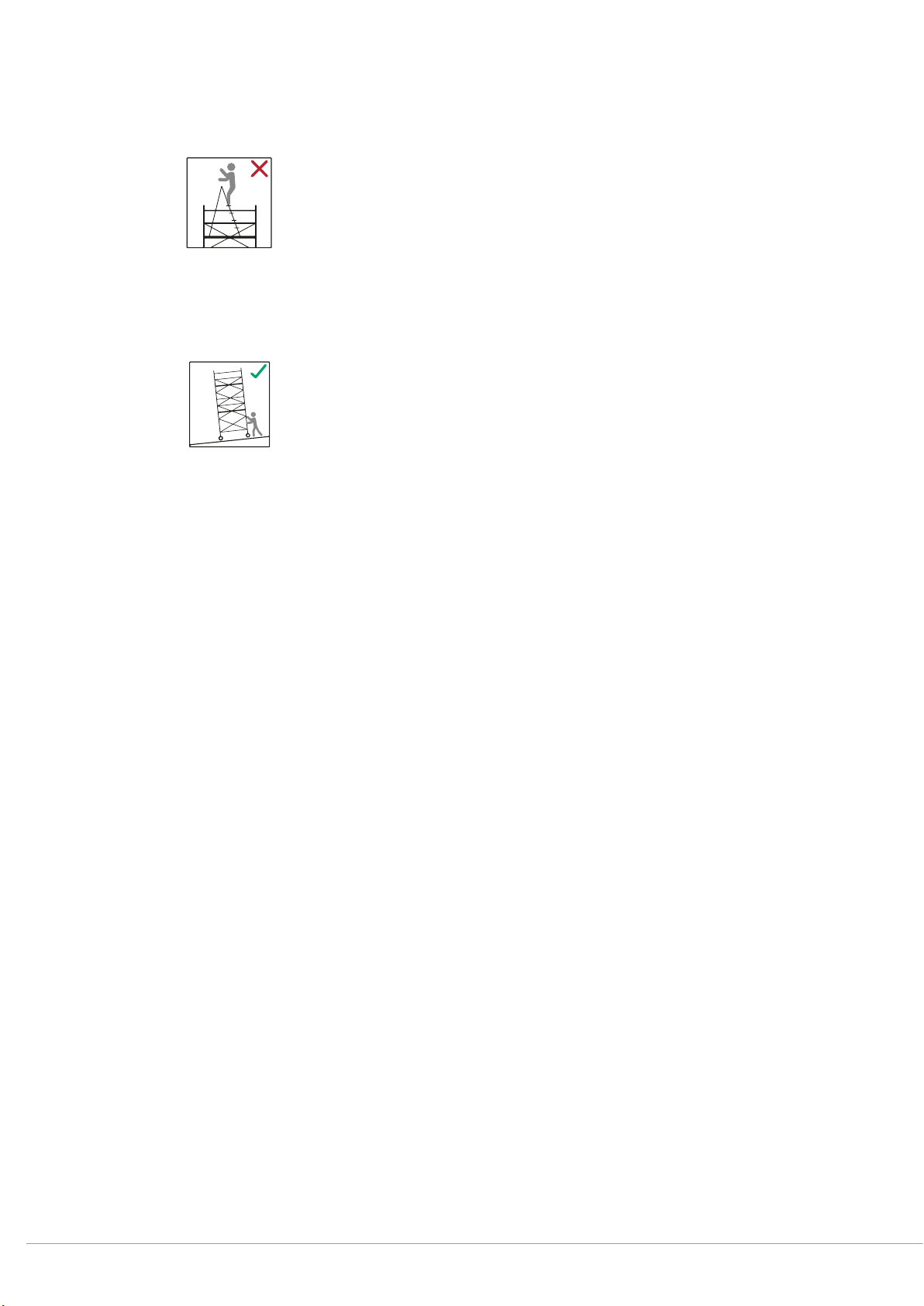

2.1 Safety regulations.............................................................................6

2.2 Usage regulations ...........................................................................7

2.3 Working on electrical equipment with the scaffold unit.................8

2.4 Other applicable safety instructions ............................................... 9

2.5 Technical data ..................................................................................9

2.6 General assembly instructions MultiTowerS-PLUS1T and 2T... 10

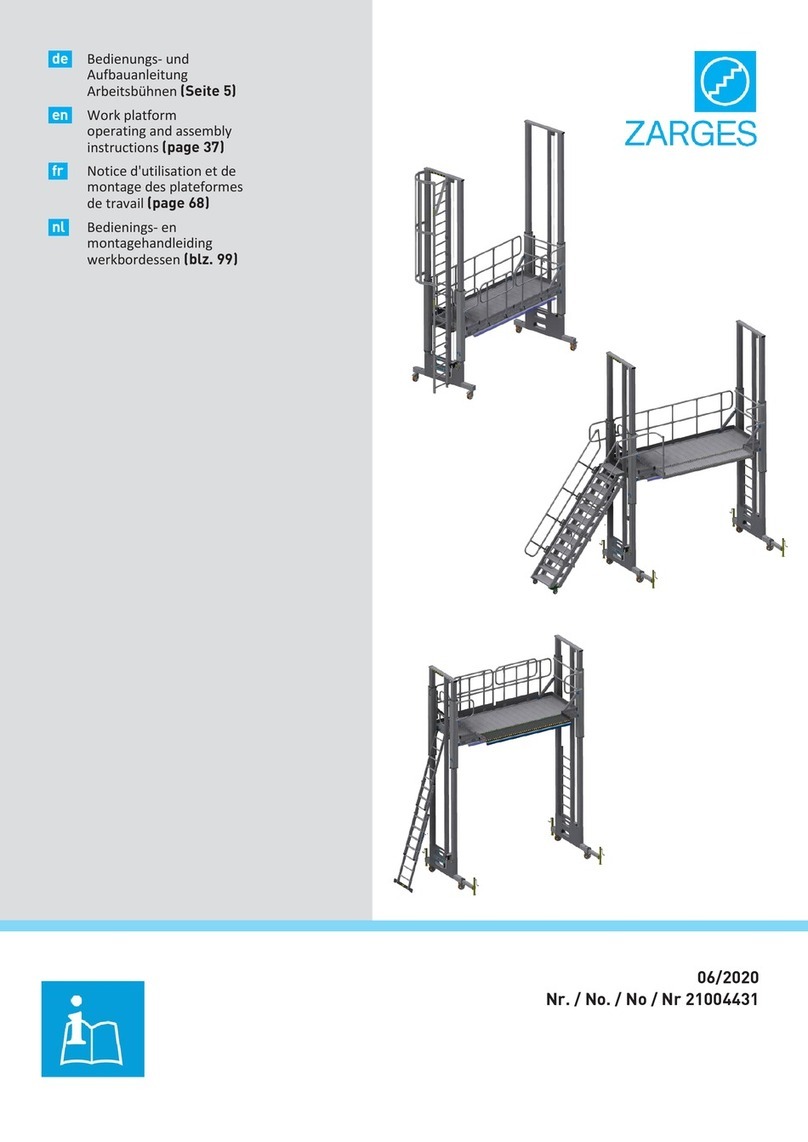

2.7 Overview of scaffolding types MultiTower S-PLUS 1T and 2T...... 15

2.8 General assembly instructions CompactMasterS-PLUS1T

and 2T.............................................................................................. 17

2.9 Overview of scaffolding types CompactMaster S-PLUS 1T

and 2T.............................................................................................. 24

2.10 Note on dismantling the scaffold tower ........................................ 25

2.11 Basic dimensions ...........................................................................26

2.12 Identification ...................................................................................28

2.13 Parts list incl. ballasting ................................................................29

2.14 Assembly drawings ........................................................................35

3 Structural safety regulations ......................................................... 37

3.1 General information ...................................................................... 37

3.2 Attaching the ballast ...................................................................... 37

3.3 Attaching the anti-twist device ..................................................... 37

3.4 Maintenance, servicing, storage and cleaning ............................. 38

3.5 Testing the scaffold unit components ........................................... 38

4 Spare parts..................................................................................... 40

en Assembly and Usage Instructions MultiTower S-PLUS 1T and 2T

CompactMaster S-PLUS 1T and 2T