ZEPIA Energy ApS ZEPIA301/ZEPIA601/ZEPIA1001 User Manual (from SW v2.10) 2

ZEPIA301, ZEPIA601 and ZEPIA1001

Battery Charger Families

Microprocessor controlled, continuous duty,

fully programmable, multi-stage battery charger and battery monitor

Batteries have to be properly charged to achieve long term reliability. The ZEPIA301, 601 and 1001

charger families are fully programmable accordingly to the battery manufacturer charging

specifications. The parameters may be set in the factory or in the field through a unique PC

interface over the charger battery output leads. Through the same interface not only the charging

parameters but also a lot of other information is accessible like: charged amp-hours for the last 32

chargings, charging times, error information, voltages at which charging has been started etc.

PRODUCT FEATURES:

•Fully automatic operation

Charger may be left permanently attached to the batteries. It takes care about battery charging and also

monitors the charging process.

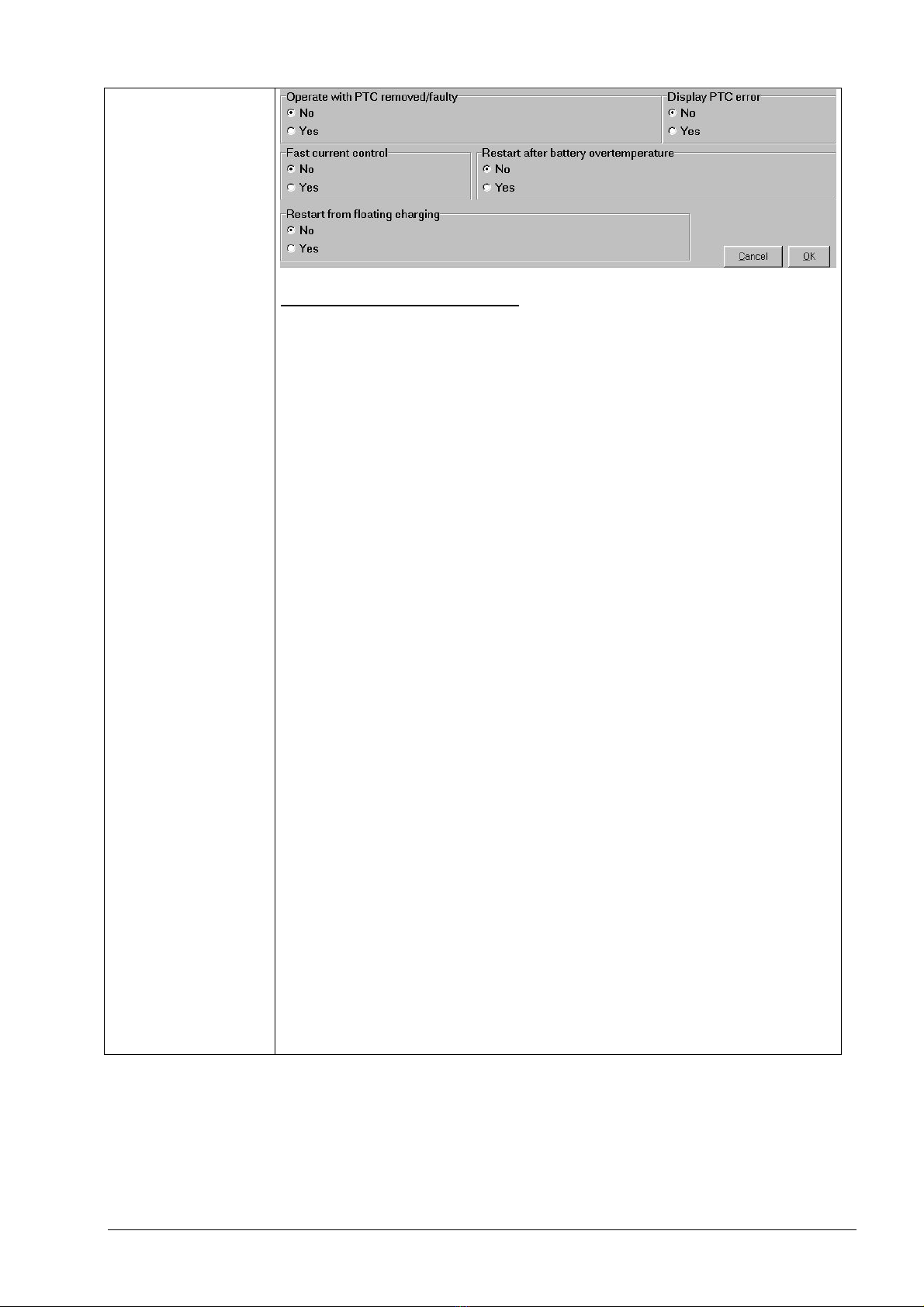

•Completely programmable: Nickel-zinc, Lithium, NiCd, NiMH or lead-acid (flooded, sealed and

traction) batteries may be charged accordingly to battery manufacturer specifications. Up to five charging

phases may be enabled to charge the battery with constant current, constant voltage or floating charge. For

each of the charging phases a lot of parameters may be set as: max. current and voltage, max. charging time

for that phase etc. (see example). Each charging phase (except the first one) may be conditionally executed

after a defined number of Ah put into the battery or after a defined number of completed 1st charging phases.

The fully automatic equalization charging phase is achievable with standard parameter set-up and may be

executed after every completed charging or after pre-defined number of chargings or charged Ah's.

Programmable automatic top-up cycle prevents self discharge during non-operational periods - charger starts

charging after a pre-defined number of days or when the battery voltage is lower than the parameter value.

The charger is fully re-programmable without opening the box. The software for the PC and a Z3610IF adapter

is all what you need.

•Battery monitor and Ah counter

This charger is also a battery monitor at no additional cost. It collects data about how the battery has been

charged:

total number of charging starts and total number of connections to the battery,

at what battery voltage the charging has been started – frequent deep discharges can be monitored: 16

voltage windows between 18 and 24V (24V charger) or between 36 and 48 (48V charger),

total Ah charged (has the battery pack been used a lot or not) - for each charging phase Ah counting

may be separately enabled (for example: Ah are not measured for the floating charge)

for each charging phase Ah counting may be separately enabled (for example: Ah are not measured for

the floating charge phase),

how many Ah have been put into the battery during the last 32 chargings (Ah counters tell you if the

battery capacity degrades or if the battery has been properly charged and also how the vehicle has been

used), measurement of the charging time for the last charging (each charging phase separately) and for

all chargings together.

This data may be accessed trough the same PC interface as for the charger parameters.

•High precision

Every charger is factory calibrated - no additional user calibration is necessary. No potentiometers or other

movable parts are used, therefore no vibration or corrosion problems for chargers built into the vehicles.

•Temperature compensation

The charger adjusts the charging voltage to compensate for the battery temperature, providing an accurate

charge in any climate. A low cost external battery temperature sensor may be used to monitor battery

temperature. The battery temperature monitoring and voltage compensation can be enabled for each charging

phase separately and set separately (two different values) for the main charging process and for the trickle

charge

•Battery status LED indicators

Three LED's (Error, Charging and 100%) display the executed charging phase, completed charging, float

charge. Charging LED is user programmable.

•Compact size, low weight, ruggedized construction and maintenance free operation