Safety harness Z+87R is body holding device used in fall arrest equipment complied with EN 361. The Z+87R is also equipped in work positioning belt

complied with EN 358 and special attachment loops on the shoulders to be used as a rescue harness complied with EN 1497. Maximum load of the

rescue harness is 140 kg. The harness Z+87R is made of polyester webbings with metallic connecting and adjustment buckles.

!after every 12 months of utilization, personal protective equipment must be withdrawn from use to carry out periodical detailed inspection. The

periodic inspection must be carried out by a competent person for periodic inspection. The periodic inspection can be carried out also by the

manufacturer or his authorized representative. In case of some types of the complex equipment e.g. some types of retractable fall arresters the

annual inspection can be carried out only by the manufacturer or his authorized representative.

!regular periodic inspections are the essential for equipment maintenance and the safety of the users which depends upon the continued efficiency

and durability of the equipment.

!during periodic inspection it is necessary to check the legibility of the equipment marking.

!it is essential for the safety of the user that if the product is re-sold outside the original country of destination the reseller shall provide instructions

for use, for maintenance, for periodic examination and for repair in language of the country in which the product is to be used.

!personal protective equipment must be withdrawn from use immediately when any doubt arise about its condition for safe use and not used again

until confirmed in writing by equipment manufacturer or his representative after carried out the detailed inspection.

!personal protective equipment must be withdrawn from use immediately and destroyed (or another procedures shall be introduced according

detailed instruction from equipment manual) when it have been used to arrest a fall.

,

!a full body harness (complied with EN 361) is the only acceptable body holding device that can be used in a fall arrest system.

!the anchor device or anchor point for the fall arrest system should always be positioned, and the work carried out in such a way, as to minimise

both the potential for falls and potential fall distance. The anchor device/point should be placed above the position of the user . The shape and

construction of the anchor device/point shall not allowed to self-acting disconnection of the equipment. Minimal static strength of the anchor

device/point is 12 kN. It is recommended to use certified and marked structural anchor point complied with EN795.

!it is obligatory to verify the free space required beneath the user at the workplace before each occasion of use the fall arrest system, so that, in the

case of a fall, there will be no collision with the ground or other obstacle in the fall path. The required value of the free space should be taken from

instruction manual of used equipment.

!there are many hazards that may affect the performance of the equipment and corresponding safety precautions that have to be observed during

equipment utilization, especially:

- trailing or looping of lanyards or lifelines over sharp edges,

- any defects like cutting, abrasion, corrosion,

- climatic exposure,

- pendulum falls,

- extremes of temperature,

- chemical reagents,

- electrical conductivity.

!personal protective equipment must be transported in the package (e.g.: bag made of moisture-proof textile or foil bag or cases made of steel or

plastic) to protect it against damage or moisture.

!the equipment can be cleaned without causing adverse effect on the materials in the manufacture of the equipment. For textile products use mild

detergents for delicate fabrics, wash by hand or in a machine and rinse in water. Plastic parts can be cleaned only with water. When the equipment

becomes wet, either from being in use or when due cleaning, it shall be allowed to dry naturally, and shall be kept away from direct heat. In metallic

products some mechanic parts (spring, pin, hinge, etc.) can be regularly slightly lubricated to ensure better operation. Other maintenance and

cleaning procedures should be adhered to detailed instructions stated in the manual of the equipment.

!personal protective equipment should be stored loosely packed, in a well-ventilated place, protected from direct light, ultraviolet degradation, damp

environment, sharp edges, extreme temperatures and corrosive or aggressive substances.

IDENTITY CARD

PERIODIC EXAMINATION AND REPAIR HISTORY

1

2

DATE

REASON FOR

ENTRY PERIODIC EXAMINATION

OR REPAIR

3

4

SERIAL NUMBER

USER NAME

DATE OF MANUF.

DATE OF PUTTING

INTO OPERATION

DATE OF PURCHASE

IT IS THE RESPONSIBILITY OF THE USER ORGANISATION TO PROVIDE THE IDENTITY CARD AND TO FILL IN THE DETAILS REQUIRED. THE IDENTITY CARD SHOULD BE

FILLED IN BEFORE THE FIRST USE BY A COMPETENT PERSON, RESPONSIBLE INTHE USER ORGANIZATION FOR PROTECTIVE EQUIPMENT. ANY INFORMATION

ABOUT THE EQUIPMENT LIKE PERIODIC INSPECTIONS, REPAIRS, REASONS OF EQUIPMENT'S WITHDRAWN FROM USE SHALL BE NOTED INTO THE IDENTITY CARD

BY A COMPETENT PERSON. THE IDENTITY CARD SHOULD BE STORAGED DURING A WHOLE PERIOD OF EQUIPMENT UTILIZATION. DO NOT USE THE EQUIPMENT

WITHOUTTHE IDENTITYCARD. ALLRECORDS IN THE IDENTITY CARD CAN BE FILLED IN ONLY BYA COMPETENTPERSON.

REF. NUMBER

DEFECTS NOTED,

REPAIRS CARRIED OUT

AND OTHER REVELANT INFORMATIONS

NAME AND SIGNATURE

OF COMPETENT PERSON

PERIODIC

EXAMINATION

NEXT DUE DATE

EN 1497:2007

Instruction Manual

READ CAREFULLY BEFORE USE

THE EQUIPMENT

EN 361:2002

ADMISSIBLE TIME OF USE

Safety harness can be used for 5 years from a date of putting the

harness into operation. After this period the harness

manufacturer's .

The manufacturer's inspection can be carried out by:

- manufacturer

- or person recommended by manufacturer

- or company recommended by manufacturer.

During this inspection will be established admissible time of harness

use till next manufacturer's inspection.

The harness

must be

withdrawn from use to carry out detailed inspection

must be withdrawn from use immediately and destroyed

when it has been used to arrest a fall.

EN 358:1999

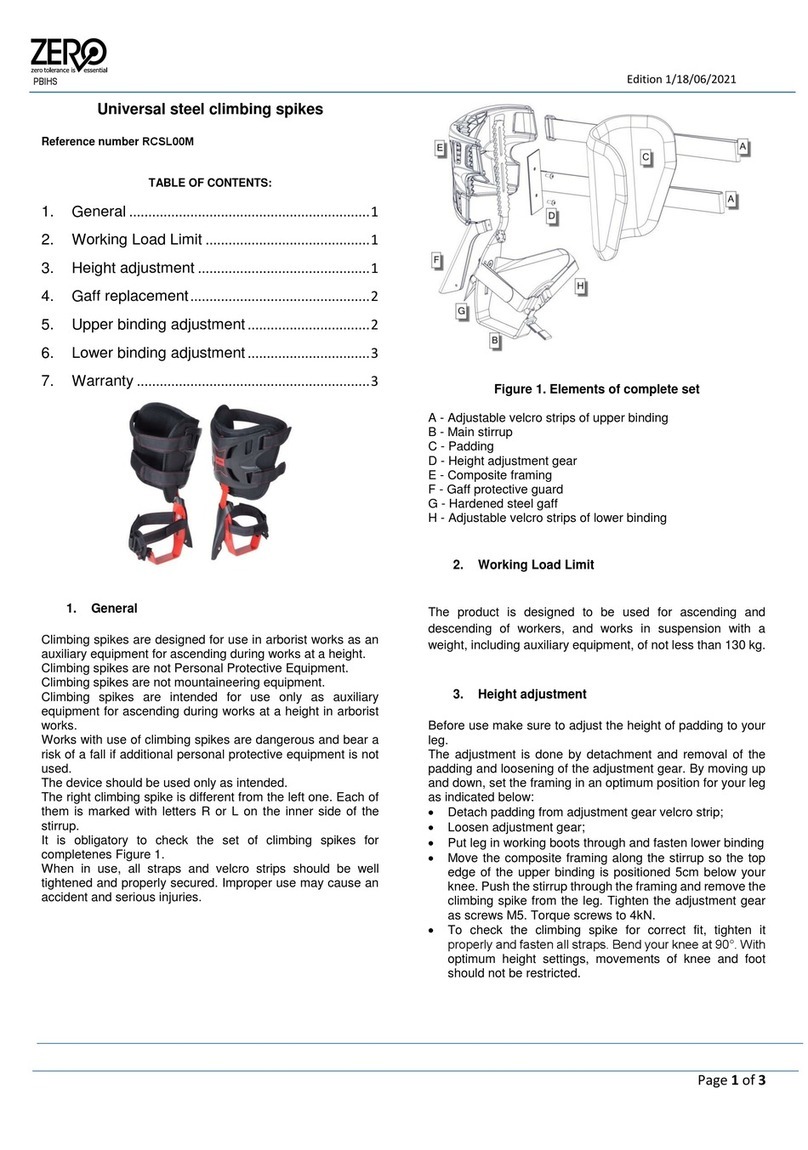

dorsal attachment D ring

for fall arrest systems

extension lanyard

for fall arrest systems

crossing plate

work

positioning belt

connecting

buckle

frontal

attachment loops

for fall arrest

systems

leg strap

connecting

buckles

chest strap

connecting buckle

lateral

attachment rings

for work positioning

systems

shoulder strap

adjustment

buckles

shoulder

attachment loops

for rescue

equipment

shoulder

straps

leg

straps

SIZES

The harness is manufactured in two sizes:

- universal: M-XL

- extra large: XXL

model marking

marking of the manufacturer

or distributor

caution: read the manual

CE marking and number

of a notified body controlling

manufacturing of the equipment (art. 11)

number / year

of the European standards

the equipment conform

size

month/year of manufacture

type of the device

CONTENT OF HARNESS IDENTITY LABEL

MODEL AND

TYPE OF EQUIPMENT

Notified body, at which the European certification

was performed and which supervises

the production of the equipment:

APAVE SUDEUROPE SAS - CS 60193

13322 MARSEILLE CEDEX 16 - FRANCE

device serial number

lateral

attachment

D-rings

for work

positioning

systems

HTP1679

SAFETY/RESCUE HARNESS

Size: M-XL

Date of manufacture: MM/YYYY

Serial number: XXXXXXX

EN 361:2002

EN 358:1999

EN 1497:2007 - max. 140 kg

zero tolerance is essential

HTP1679

zero tolerance is essential

Zero Advanced Height Safety

Head Office, PBI Height Safety Ltd

PO Box 39048, Harewood 8545

10 Holt Pl, Harewood 8053

Christchurch, New Zealand

P: +64 3357 0093 F: +64 3360 2199

Freephone: (NZ) 0800 357 003

(AUST) 1800 421 608

E: info@zero4heightsafety.com

www.zero4heightsafety.com

SAFETY/RESCUE

HARNESS

PBIHS