1 Introduction

Before operation, please read all instructions and warnings on the unit and in this manual. Please keep the manual where

it can be accessed easily.

The Z21 series inverter marketed by the Beijing Hua Xing Liu He Investment(Australia)Pty Ltd. (hereinafter referred to as Zeus Appollo

Solar) strictly conforms to all related safety requirements during design and testing phases.

Safety regulations relevant to the installation location shall be followed during installation, operation and maintenance.

Improper operation may result in a risk of electric shock or damage to the equipment and/or property.

01

2 Important Safety Warning

02

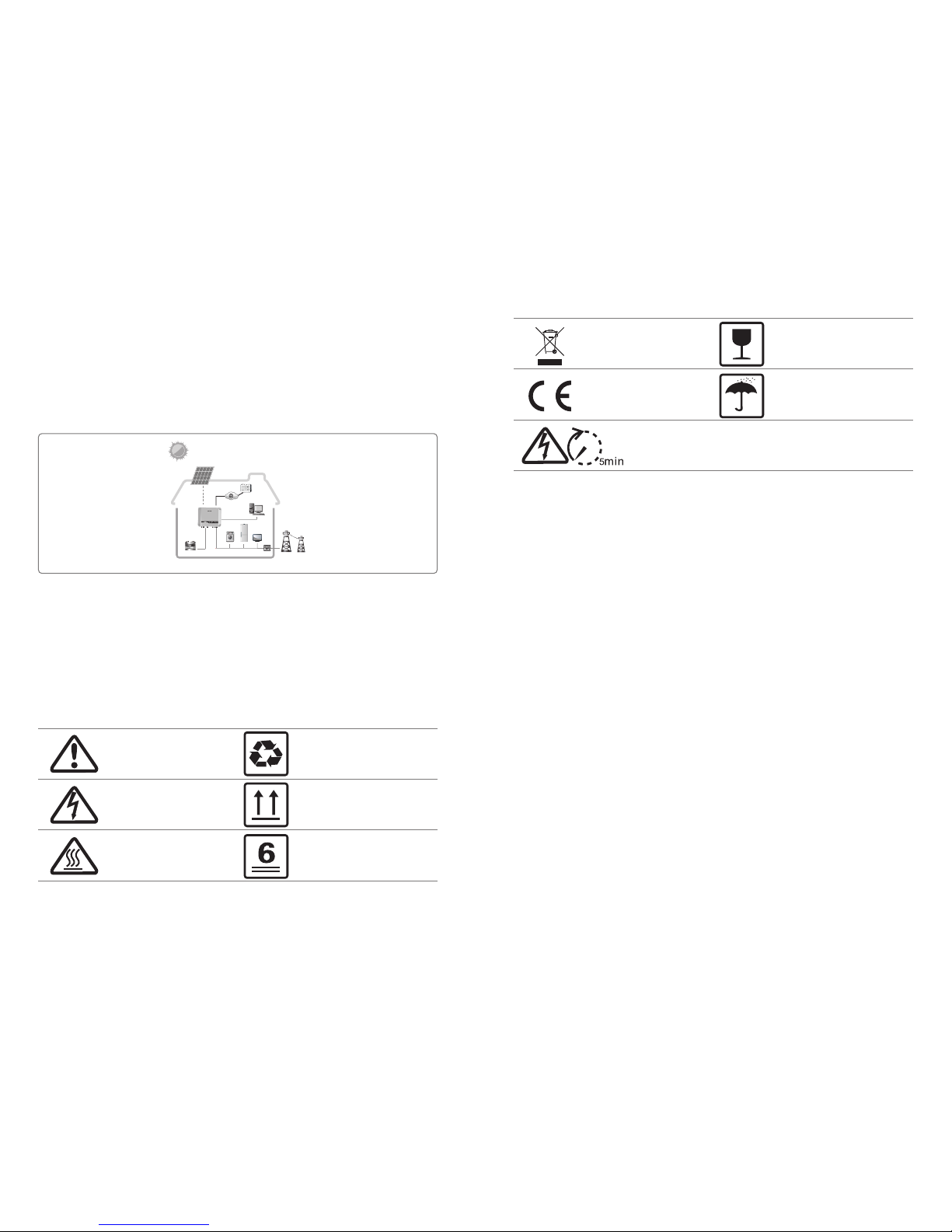

Caution!

Failure to observe a warning indicated in

this manual may result in injury.

Danger of high voltage and electric shock!

Danger of hot surface!

Components of the product can be recycled.

This side up; the package must always be

transported, handled and stored in such a way

that the arrows always point upwards.

No more than six (6) identical packages may

be stacked on each other.

Zeus Appollo Solar Z21 series hybrid inverters are bidirectional which enables the PV system to direct excess power to a battery

storage facility.

Energy produced by the PV system is designed to optimize consumption; excess energy is used to charge the batteries, and when

fully charged power is then fed into the public grid.

When PV energy output is insufficient to support the connected loads, the system automatically draws power from the batteries if

they are charged and available. If the battery capacity is insufficient to meet consumption requirements, power will be automatically

sourced from the public grid.

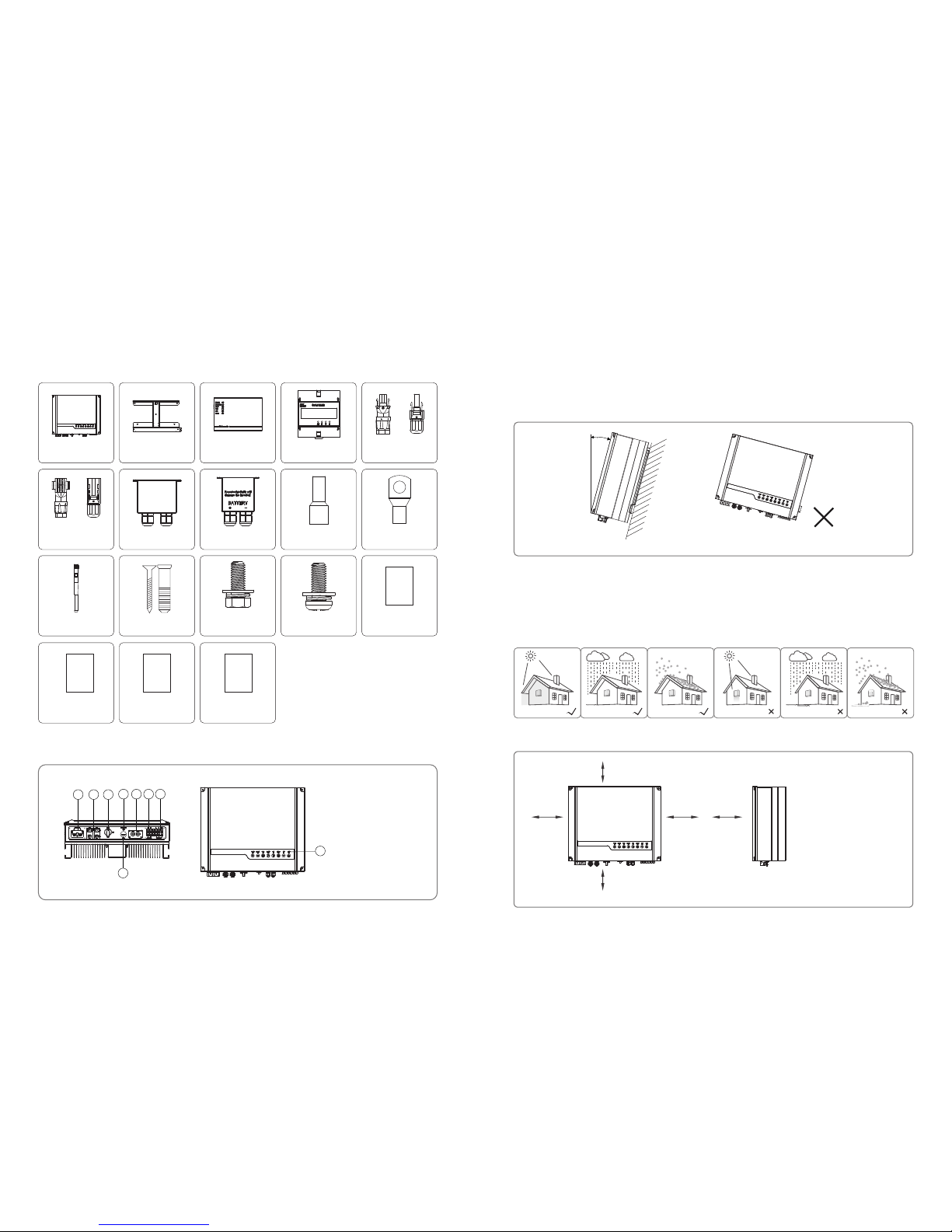

Zeus Appollo Solar Z21 series inverter is designed for both indoor and outdoor use.

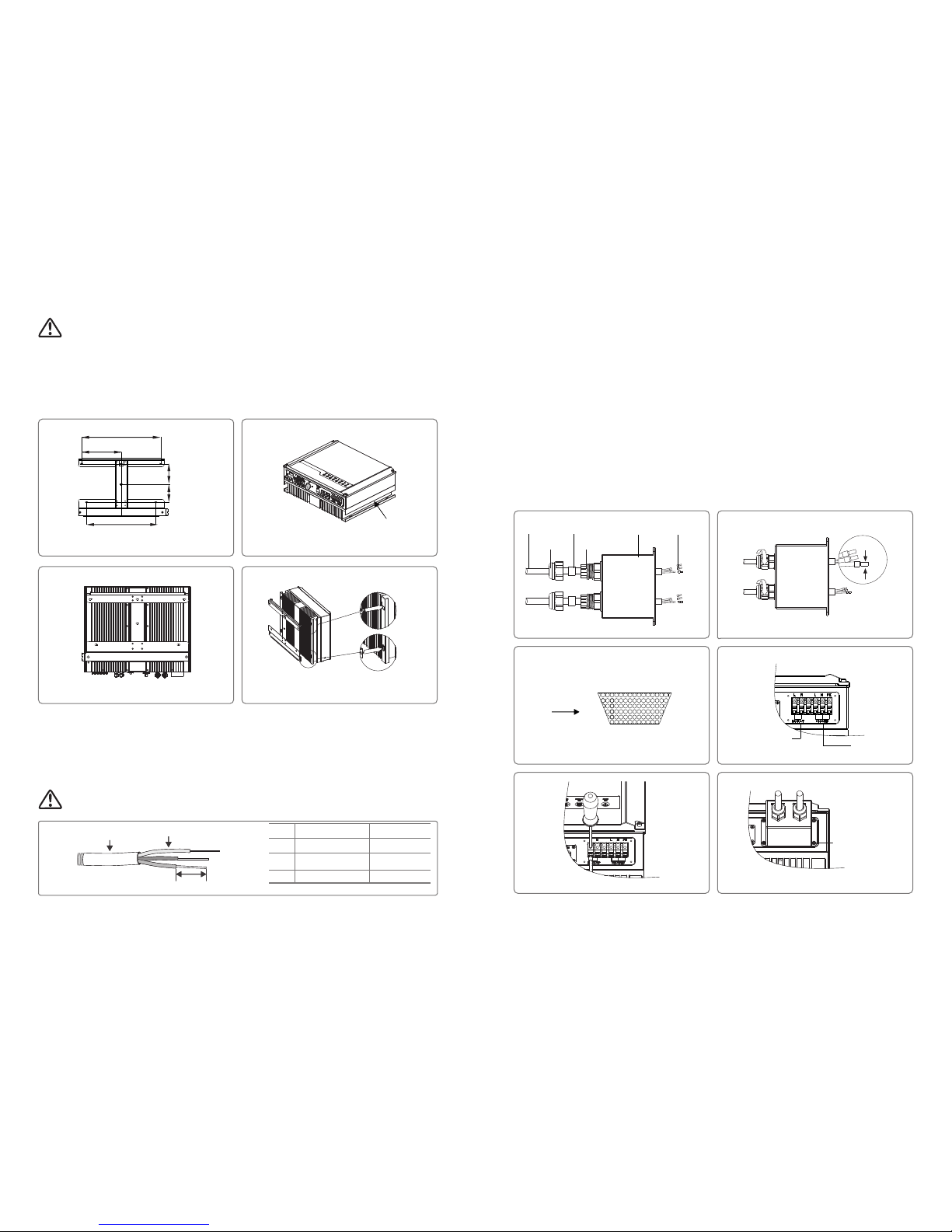

Figure 1-1 Basic hybrid PV system overview

2.1 Symbols

Product should not be disposed as

household waste.

CE Mark

Keep dry; the package/product must be

protected from excessive humidity and must be

stored under cover.

Signals danger due to electrical shock and indicates the time (5 minutes) to allow after the

inverter has been turned off and disconnected to ensure safety in any installation operation.

The package/product should be handled

carefully and never be tipped over or slung.

2.2 Safety

● Installation, maintenance and connection of inverters must be performed by qualified personnel, in compliance with local electrical

standards, wiring rules and the requirements of local power authorities and/or companies (for example : AS 4777 and AS/NZS

3000 in Australia).

● To avoid electric shock, DC input and AC output of the inverter must be terminated at least 5 minutes before performing any

installation or maintenance.

● The temperature of some parts of the inverter may exceed 60℃ during operation. To avoid being burnt, do not touch the inverter

during operation. Let it cool before touching it.

● Ensure children are kept away from inverters.

● Do not open the front cover of the inverter. Apart from performing work at the wiring terminal (as instructed in this manual),

touching or changing components without authorization may cause injury to people, damage to inverters and may void the

warranty.

● Static electricity may damage electronic components. Appropriate procedures must be adopted to prevent such damage to the

inverter; otherwise the inverter may be damaged and the warranty will be voided.

● Ensure the output voltage of the proposed PV array is lower than the maximum rated input voltage of the inverter; otherwise the

inverter may be damaged and the warranty will be voided.

● When exposed to sunlight, the PV array generates dangerous high DC voltage. It will cause potential danger to people. Please

strictly follow the instruction provided.

● PV modules should have an IEC61730 class A rating.

● If the equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

● To completely isolate the inverter: switch off the DC switch, disconnect the PV terminal, disconnect the battery terminal, and

disconnect the AC terminal.

● Completely isolate the inverter before maintenance. Do not service other areas of the inverter when undertaking maintenance!

● Do NOT insert or extract the AC and DC terminals when the inverter is in operation.

● In Australia, the inverter internal switching does not maintain the neutral integrity, neutral integrity must be addressed by external

connection arrangements like the example proposed in the diagram 4.10.

● In Australia, the output of backup side in switchbox should be labeled 'main switch UPS supply', the output of normal load side in

switchbox should be labeled 'main switch inverter supply'.