Amendment of the original operating

instructions

Inspection of the bolted connection of the

worm wheel of the elevator machines

ZAS0, ZAS1, ZAS2, ZAS3

A-TIA19_04-GB

ZIEHL-ABEGG SE | Heinz-Ziehl-Straße | 74653 Künzelsau | Tel. +49 7940 16-0 | drives@ziehl-abegg.de | www.ziehl-abegg.de

A-TIA19_04-GB Ausgabe: 1912 Index 001 Erstellt am: 22.03.2019

Seite 4/8

As an option, the empty elevator car can be sent to the lowest floor, by a light and controlled

activation of the manual hand release, the worm wheel can be brought to the required position as

well.

2.3.3 Inspection of tightening

The elevator must be switched off by the main

switch and protected against restart.

Do not activate the manual hand release!

Inspection goal:

Identi

ication of loose nuts.

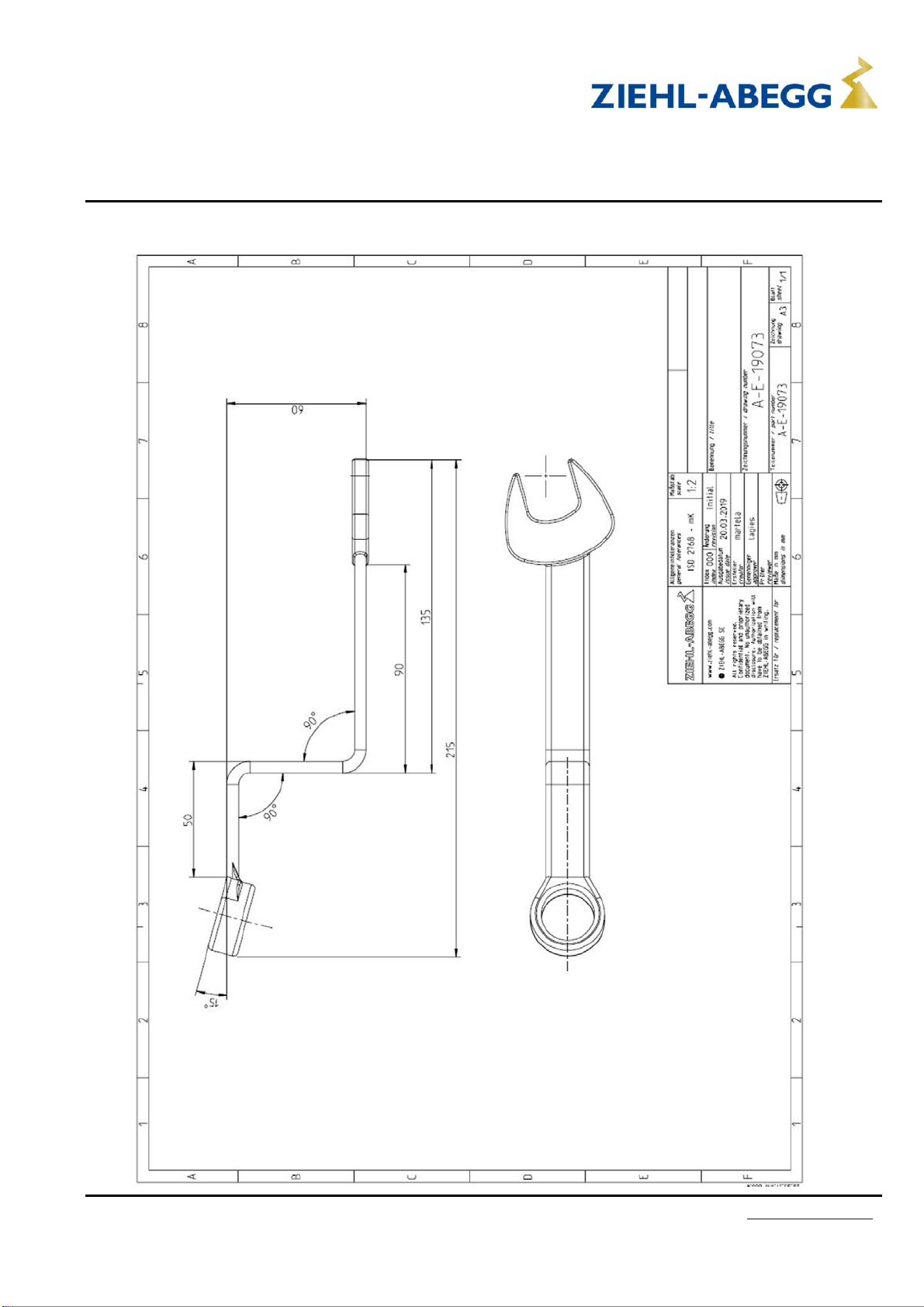

pply the suitable tool (2) onto the nut (1) of the

bolted connection and turn clockwise with

moderate force according to the following table

ithout any jerk.

On the side of the fitting bolt no spanner is

applied for counterholding.

Figure 4: Direction of the rotation of spanner for

inspection of tightening the nuts

Gearbox SW

Nut

Inspection

torque

approx

Lever

length

approx

Force

approx Force

approx

Nm mm N kg

SWG0 16 / 17 20 200 100 10,0

SWG1 18 / 19 35 220 150 15,0

SWG2 18 / 19 35 220 150 15,0

SWG3 21 / 22 55 180 300 30,0

Table 1: Overview gearboxes – spanner sizes – test forces

After the evaluation of the tightening, according to 2.3.4, the next nut has to be brought into

position according to 2.3.2.

The inspection of the bolt connection of the worm wheel of the gearbox, is completed when all 6

nuts of the worm wheel have been inspected according to the described method above.