– 8 –

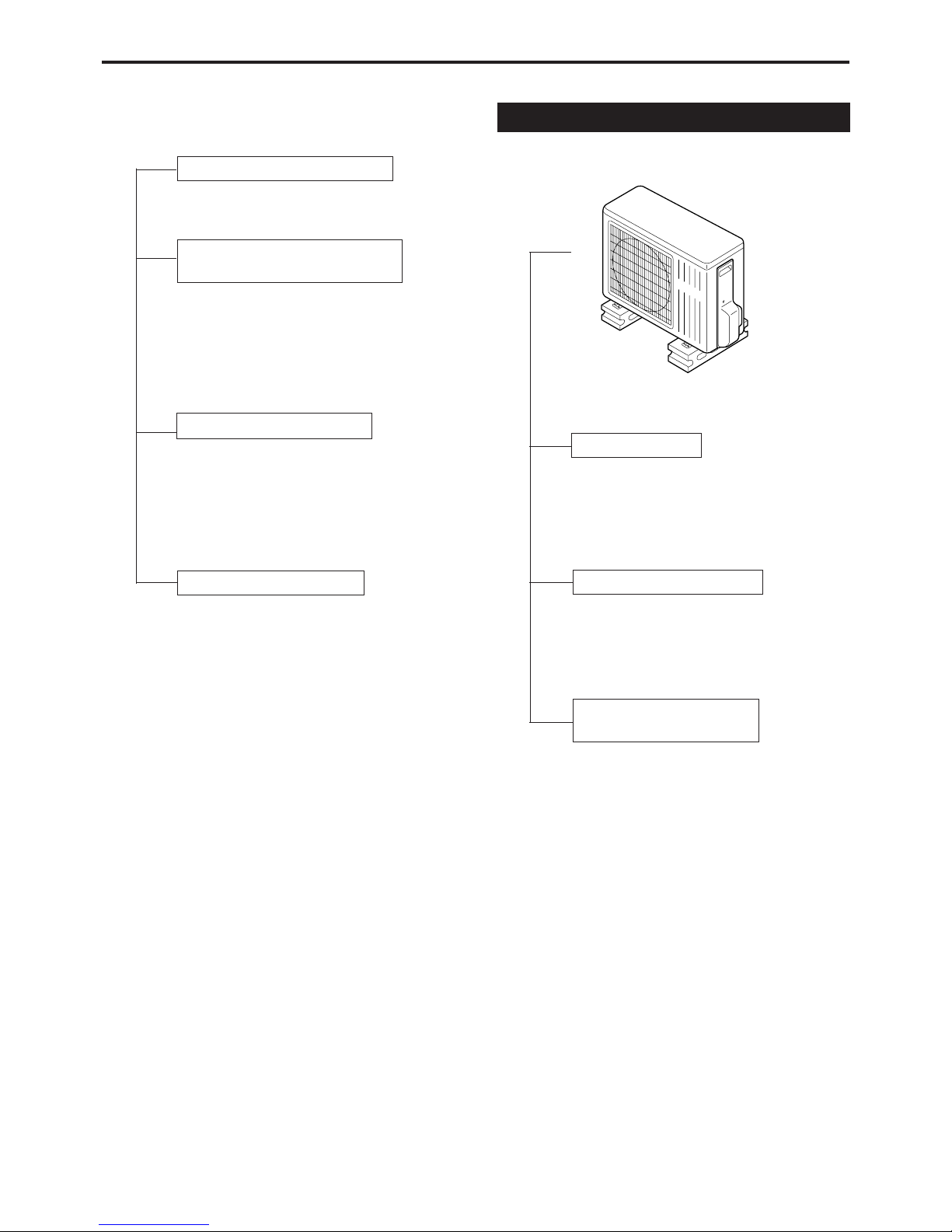

OUTDOOR UNIT

Inverter control

Inverter control reduce the ON/OF times

of compressor,so can keep the room

temperature changeless during

operation.

Electricity consumption

Inverter control can operate with less

electricity consumption than normal air

conditioner.

Deice(Defrost) control

(for outdoor unit panel)

Deice operation automatically starts

when the outdoor temperature is lower

than 2℃and the ice is formed on the

bottom of outdoor unit.

Hot-start control (heating)

The indoor fan stops until the evaporator

piping temperature will be reached.

Anti-freezing control for the

evaporator

Compressor will be stopped when the

evapolator’s piping temperature is below

2℃for one minute.

Compressor will be restarted when the

evaporator’s piping temperature is above

2℃.

Airflow direction control

Automatic airflow direction control

The louver automatically swings up and

down (cooling, dry)...horizontal and 35°

downward.

The louver is set at 70°downward

during heating operation.

Auto recovery function

If there is any power failure during

operation, operation status before power

failure is memorized.

3〜4 minutes after power recovery, the

unit restarts automatically with previous

operation status memorized.

(3〜4 minutes is protective time for

compressor.)

Attention

Because of Auto recovery function, if

shutting off the power supply during

operation, the unit may restart

irrespective your intention when turning

on the power supply next time.

If the unit is not to be used for a long

time, shut off the power supply after

terminating all operation with remote

controller.

FUNCTIONS