DDOC00188 enu / 2016-08-31 / Index a

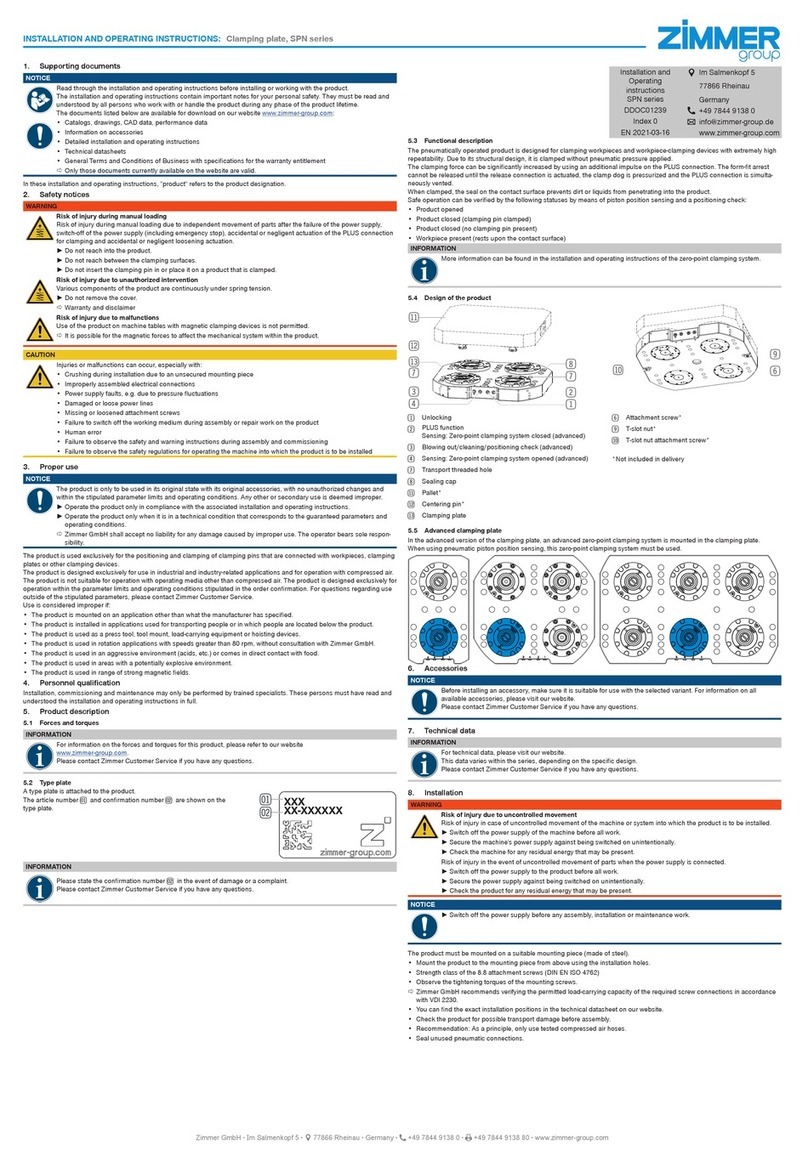

INSTALLATION AND OPERATING INSTRUCTIONS: Pneumatic GSI series O-Ring gripper

Zimmer GmbH ●Im Salmenkopf 5 ●77866 Rheinau, Germany ●Phone: + 49 7844 9138-0 ● Fax: + 49 7844 9138-80 ●www.zimmer-group.de

Spread jaws:

►Retract clamping jaws 4,

No interference contour when retracting them into the workpiece.

►Adjust the immersion depth of the spread jaws into the workpiece

Contact surface Aon the spread jaw 1must be the

same height as the bottom edge Cof the annular

groove in the workpiece.

►Retract the gripper from the installation position.

►Increase the stroke of the spread jaw 1until it touches the workpiece using

adjustment ring 7.

►After, reduce the stroke by approximately 0.5 mm.

Check the distance by pushing in a workpiece.

Twisting the adjustment ring 7is only possible in a depressurized

state.

The gripper jaws must not touch the workpiece when they are

extended.

►The jaw set and the retraction depth are not set,

some fine adjustments using the adjustment rings may be neces-

sary after a test.

►Attach the sensors.

►Perform a test run in a single step procedure

Please adhere strictly to the gripper's flow diagram

A 1 C

0.5 mm

Note:

The stroke limitation of the piston must occur via the

internal limit stop of the gripper (adjustment ring),

► not indirectly via the workpiece!

6.6. Position sensing sensors

em

en

eo

em Piston position query dm

for clamping jaws

en Piston position query dn

for spread jaws

eo Piston position query do

for wiper

The clamping position query via magnetic eld sensors takes place indirectly via

a magnet xed to the piston.

The magnetic eld sensor cr is inserted into the integrated slot (9) to set the

switch point.

► Insert the magnetic eld sensor cr into the integrated slot 9

► Turn the mounting screw cq using an Allen key

Observe the maximum tightening torque;

refer also to the magnetic eld sensor operating instructions

► Move the respective pistons into the respective end position and adjust the

magnetic eld sensor there

2 positions for each piston

► Push the magnetic eld sensor cr until it reaches the switch-on point (LED on).

► Mark the point

► Push the magnetic eld sensor cr until it reaches the switch-o point (LED o).

► Mark the point

► Then push the sensor back again until it reaches the switch-on point (LED on).

The optimum magnetic eld sensor position cr is between the two

tagged points.

► Repeat the process for each piston end position

cq

cr

9

10