INSTALLATION AND OPERATING INSTRUCTIONS: 2-jaw parallel grippers with long stroke, electric, GEH6000IL series

INSTALLATION AND OPERATING INSTRUCTIONS: 3-jaw concentric grippers with long stroke, electric, GED6000IL series

3

DDOC00212 / lEN / 2019-10-28

Zimmer GmbH ●Im Salmenkopf 5 ●77866 Rheinau, Germany ●+49 7844 9138 80 ● +49 7844 9138 80 ●www.zimmer-group.com

Content

1. Supporting documents.......................................................................................................................................................5

2. Safety instructions...............................................................................................................................................................5

3. Proper use............................................................................................................................................................................6

4. Personnel qualication .......................................................................................................................................................6

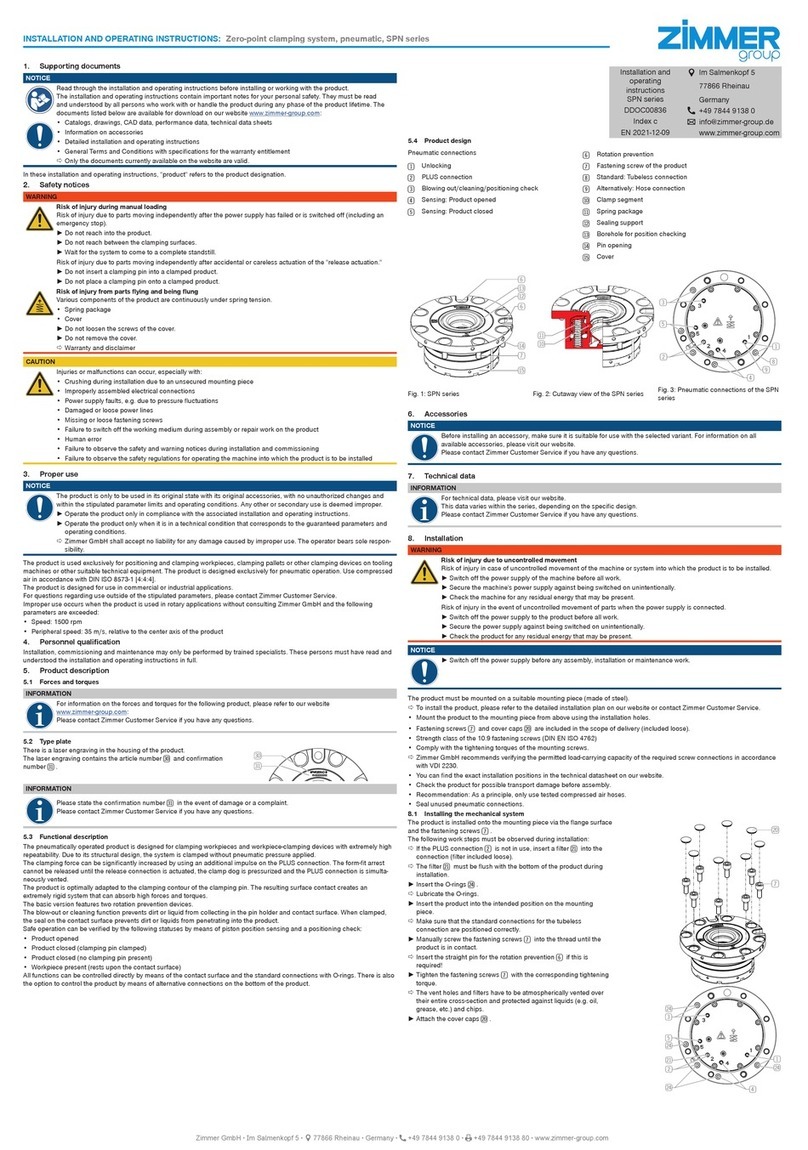

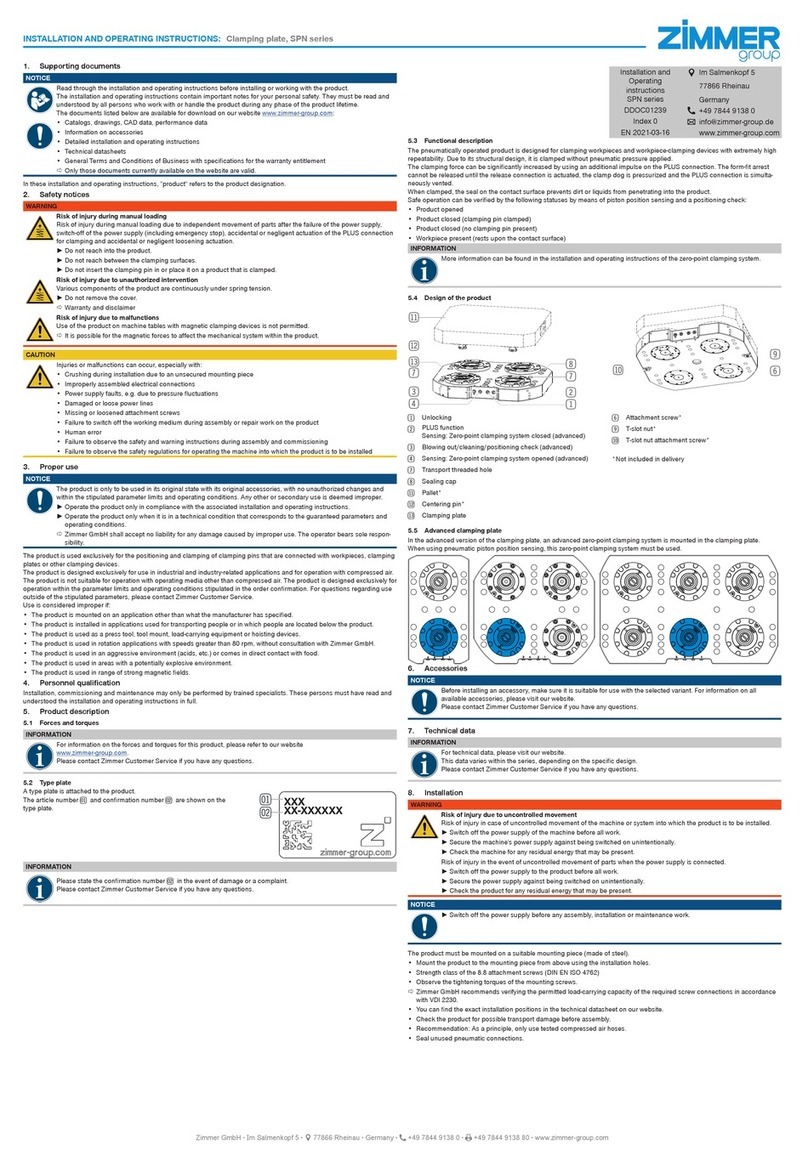

5. Product description.............................................................................................................................................................7

5.1 Possible applications........................................................................................................................................................................................7

5.2 Forces and torques...........................................................................................................................................................................................7

5.3 Type plate .........................................................................................................................................................................................................7

6. Function ...............................................................................................................................................................................8

6.1 Electrical specications....................................................................................................................................................................................8

6.2 LED display .......................................................................................................................................................................................................9

6.3 Veried conguration........................................................................................................................................................................................9

6.4 Protection classes.............................................................................................................................................................................................9

6.5 Technical data ...................................................................................................................................................................................................9

6.6 Self locking mechanism ...................................................................................................................................................................................9

7. Installation..........................................................................................................................................................................10

7.1 Safety instructions...........................................................................................................................................................................................10

7.2 Installation of the mechanical system GEH6000IL ......................................................................................................................................10

7.3 Installation of the mechanical system GED6000IL ......................................................................................................................................11

7.4 Installation of the electrical system GEH6000IL + GED6000IL ...................................................................................................................12

7.4.1 Installation of the wiring ................................................................................................................................................................12

7.4.2 “IO-Link” installation ......................................................................................................................................................................12

7.4.3 Installation of “Special gripper with a second cable” (STO connecting cable) ........................................................................13

7.5 Static charge ..................................................................................................................................................................................................14

7.6 Heat dissipation...............................................................................................................................................................................................15

7.7 Installation of accessories ..............................................................................................................................................................................15

8. Commissioning..................................................................................................................................................................15

8.1 Process data....................................................................................................................................................................................................15

8.1.1 IODD import ...................................................................................................................................................................................16

8.2 “Handshake” data transmission method ......................................................................................................................................................16

8.3 Parameter ........................................................................................................................................................................................................17

8.3.1 “ControlWord” parameter .............................................................................................................................................................17

8.3.2 “DeviceMode” parameter..............................................................................................................................................................18

8.3.3 Movement proles .........................................................................................................................................................................19

8.3.4 “WorkpieceNo” parameter............................................................................................................................................................24

8.3.5 “PositionTolerance” parameter .....................................................................................................................................................24

8.3.6 “GripForce” parameter ..................................................................................................................................................................24

8.3.7 “DriveVelocity” parameter .............................................................................................................................................................25

8.3.8 “BasePosition” parameter.............................................................................................................................................................25

8.3.9 “ShiftPosition” parameter..............................................................................................................................................................25

8.3.10 “TeachPosition” parameter ...........................................................................................................................................................26

8.3.11 “WorkPosition” parameter.............................................................................................................................................................26

8.3.12 “StatusWord” parameter ...............................................................................................................................................................26

8.3.13 “Diagnosis” parameter ..................................................................................................................................................................28

8.3.14 “ActualPosition” parameter ...........................................................................................................................................................28

8.4 “Cold start”......................................................................................................................................................................................................28

8.5 Minimum travel path .......................................................................................................................................................................................28

8.6 Referencing by “Homing” .............................................................................................................................................................................29

8.6.1 “DeviceMode” 10...........................................................................................................................................................................30

8.6.2 “DeviceMode” 14...........................................................................................................................................................................30

8.6.3 “DeviceMode” 16...........................................................................................................................................................................31

8.6.4 “DeviceMode” 17...........................................................................................................................................................................32