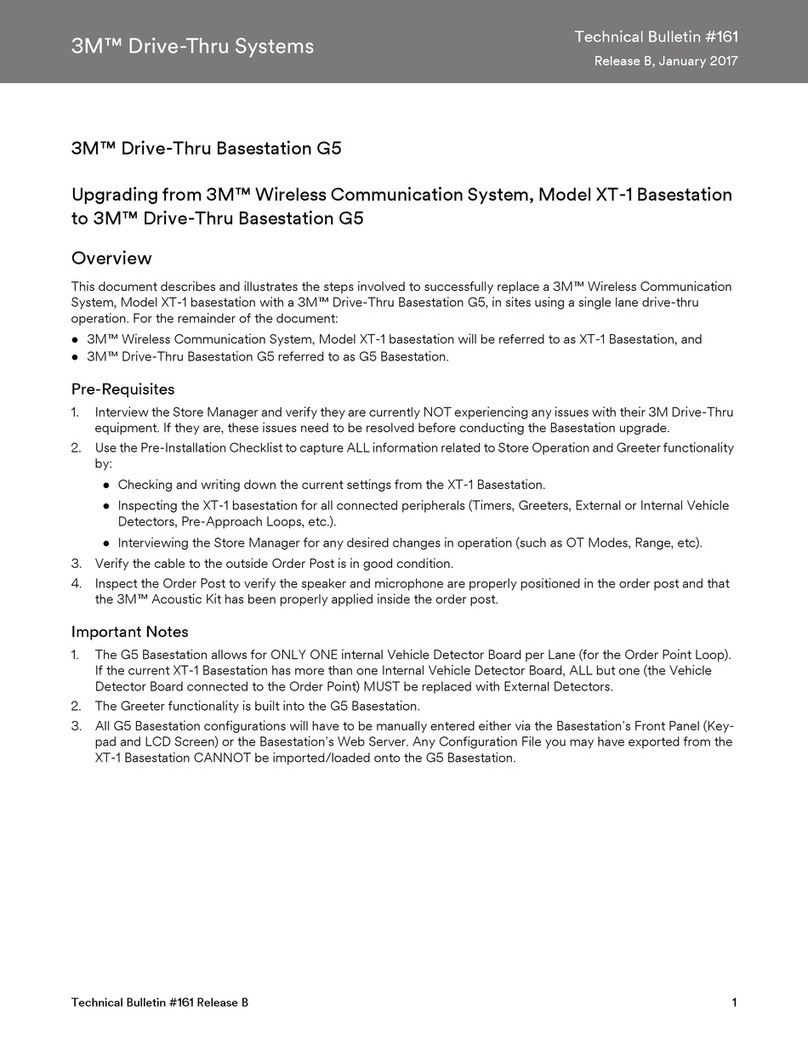

ElectronicsSide:

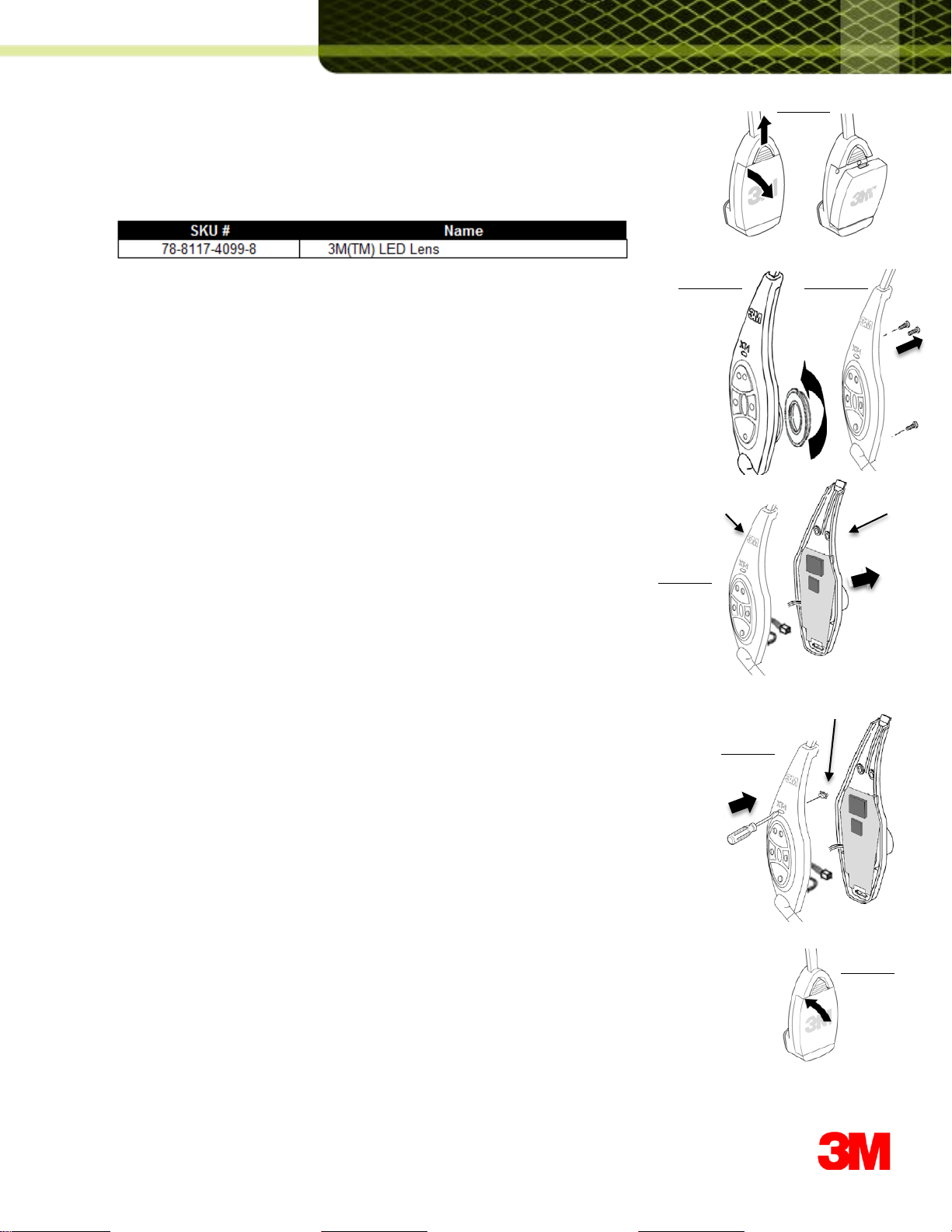

1. Removethe ear pad, ear cup, and the three screws fromthe inner case of the headset.

.

2. Separatethe case halves, ever so slightly.Carefullyraisethe inner case just over

the On-Off buttonand slide down slightly to separate.See Fig 31-a.

Support the innercase so the speakerwires are not strained.

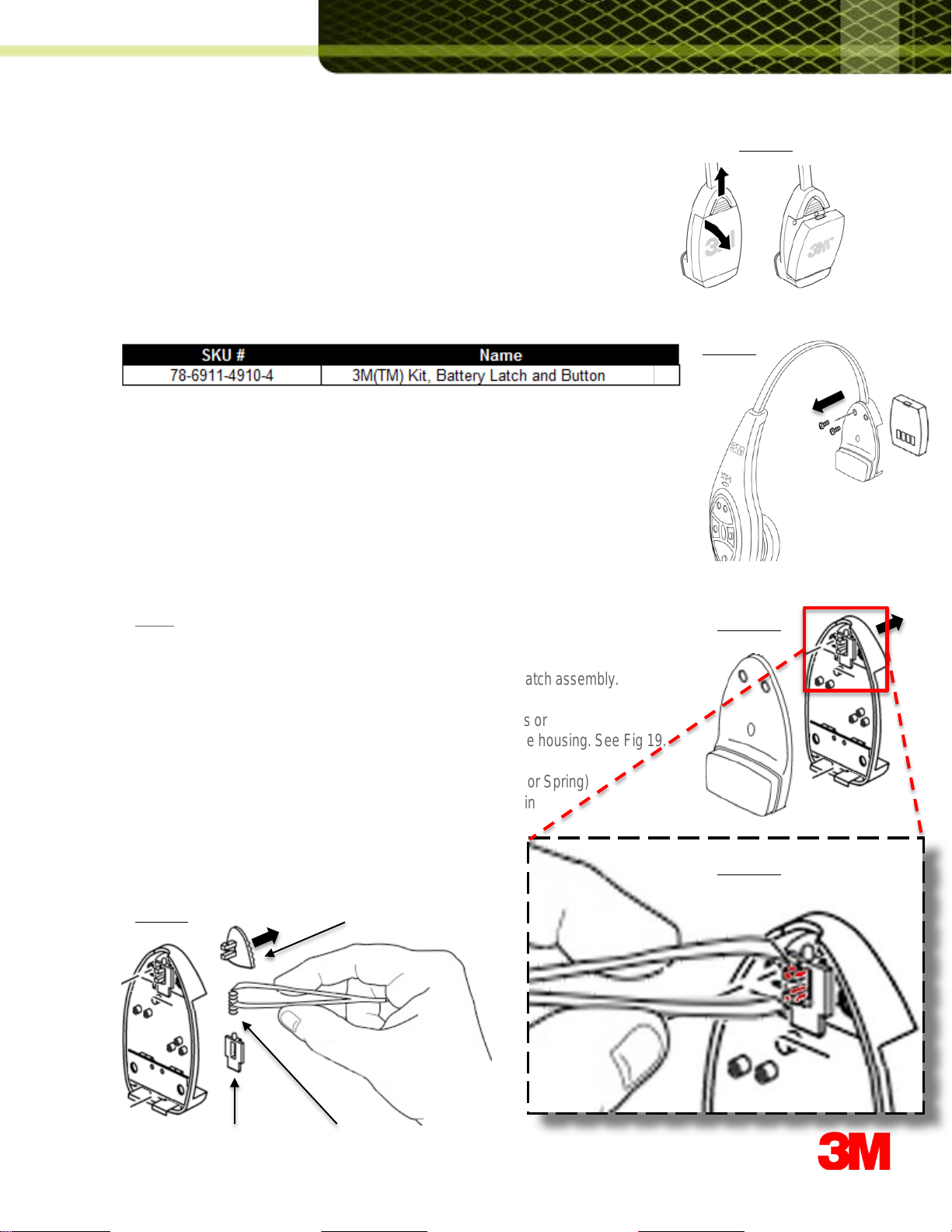

4. Disconnectthe headband's power wiring connectorlocatedat the

top of the main circuit board. See Fig 31-a.

5. Locatethe headbandclip positioned just underthe headbandentry

opening on the outer case assembly.

6.Carefullypull the power wire cable out of the top grooveof the headbandclip.

See Fig 31-b.

7. Removethe headbandclip from the headband end by rotatingit 90 degrees

and pulling it free of the headband.See Fig 31-b and Figs 32-a,b,cand d.

8. Pull the headbandassembly (including the wiring cable) free of the outer case.

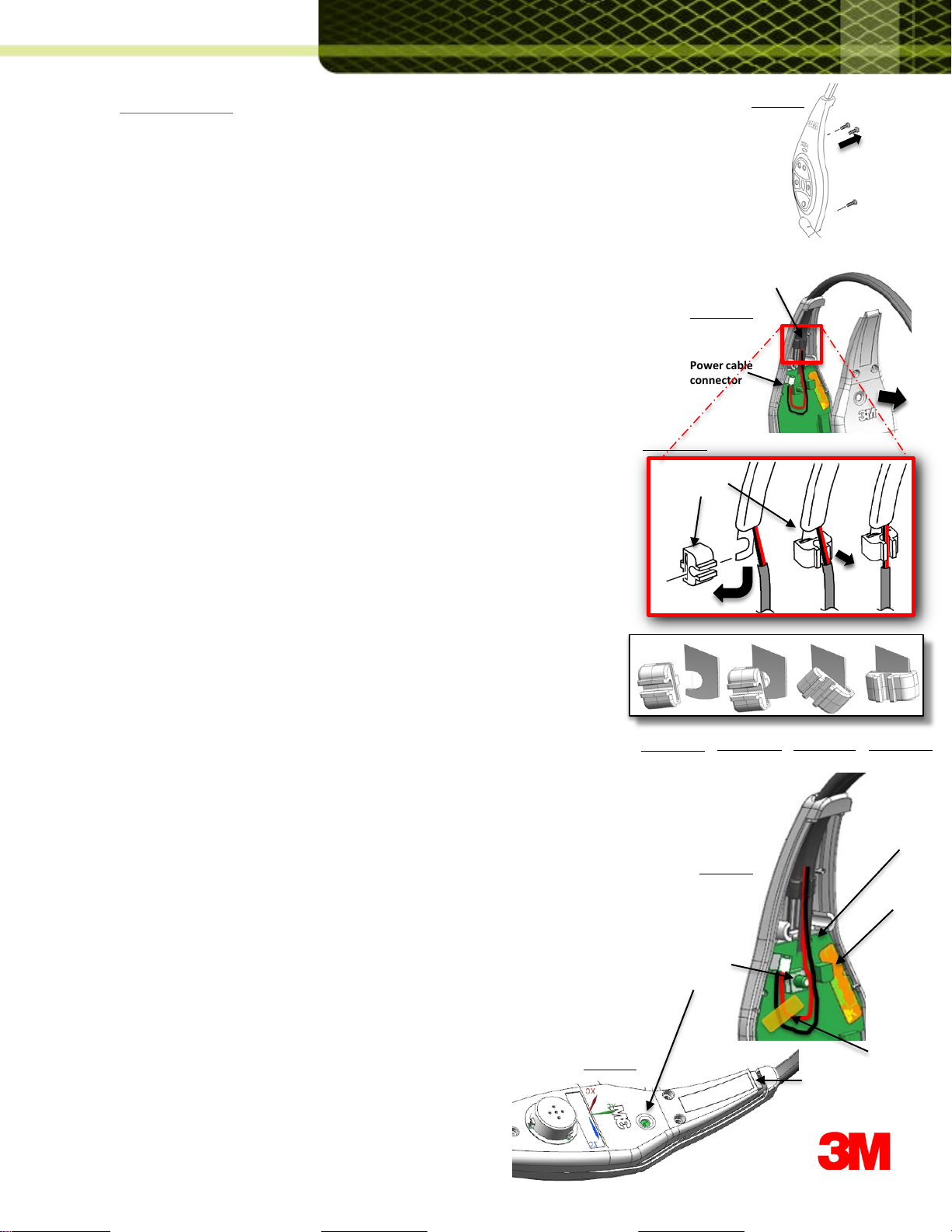

9. Insert the power cable from the replacementHeadband throughthe top of the

outer case.

Hold replacementHeadband Clip with the open wire groove facing up.

Hold the Clip so the curved portioninside the slot of the Clip faces next to the

curved sectionof the Headband end. See Fig 32-a.

Rotate the Clip 90 degreesas youslide it into the curvedsectionof

the Headbandendas shown in illustration.See Fig 32-b,32-c and 32-d.

10.Carefullypress the power wires, one on top of the other, into the

top wire groove of the Clip.

Be sure to press the wires completelydown into the wire groove.

11.Plugin the power cableconnector.

Route the power cablebetween the On-Off buttonand the large

capacitor on the PWA. See Fig 33.

NOTE: The power cable MUST routedown the center of the PWA or

the Headbandwill not extendproperly.

12.Applya strip of 3MTM ¼’’PolyimideFilm Tape to make sure the wires are

held in place as shown in Fig 29.

13. Makesure the LED Lens is still in place.Otherwise,follow the procedure

Replacing the IndicatorLED Lens to re-install the LED Lens.

14.Assemblethe case halves by insertingthe tab at the top of the inner case

through the slot at the top of the outer case and carefullylower it over

the On-Off buttonand snapit shut at the bottom. See Fig 34.

Care must be taken not to pinch anywires.

15.Replacethree case screws, ear cup, andpad.

FIGURE 31-a

FIGURE 30

Power cable

connector

Headband

Clip

FIGURE 32-a FIGURE 32-b FIGURE 32-c

Center of

the PWA

Large

capacitor

On-Off

button

Tab on top of the

inner case

FIGURE 33

FIGURE 34

3MTM 1/4’’

Polyimide Film

Tape

FIGURE 32-d

FIGURE 31-b

Headband

Clip