9

1.0 PRODUCT APPLICATION

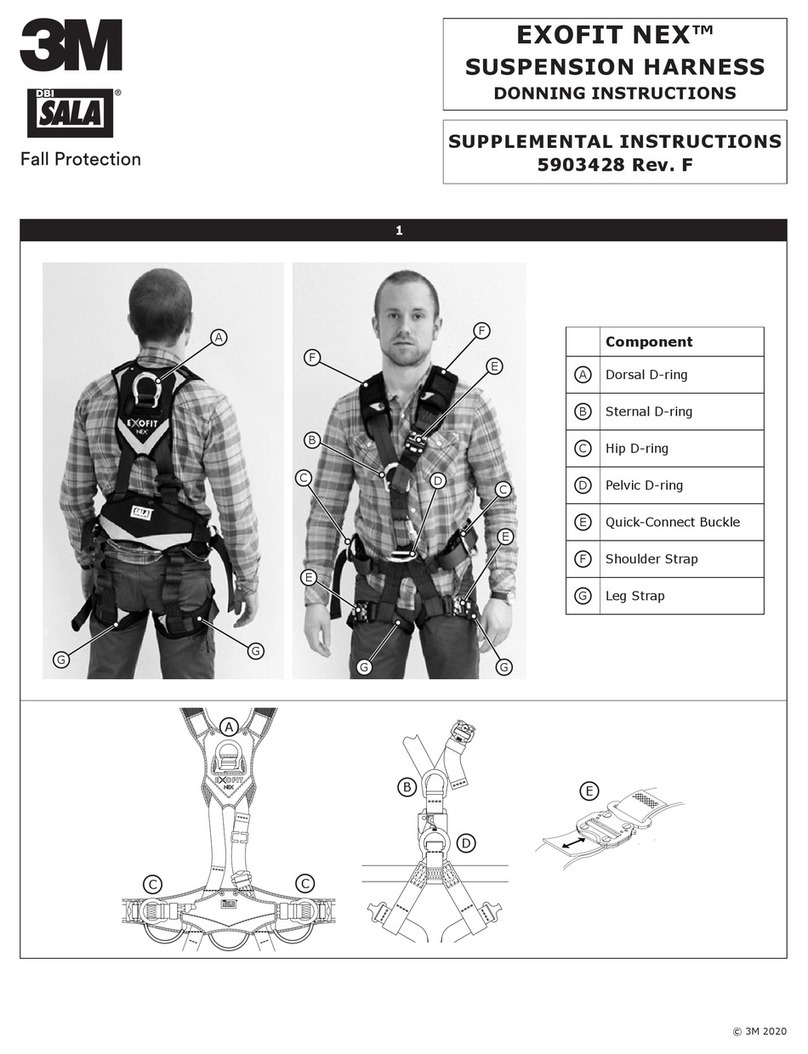

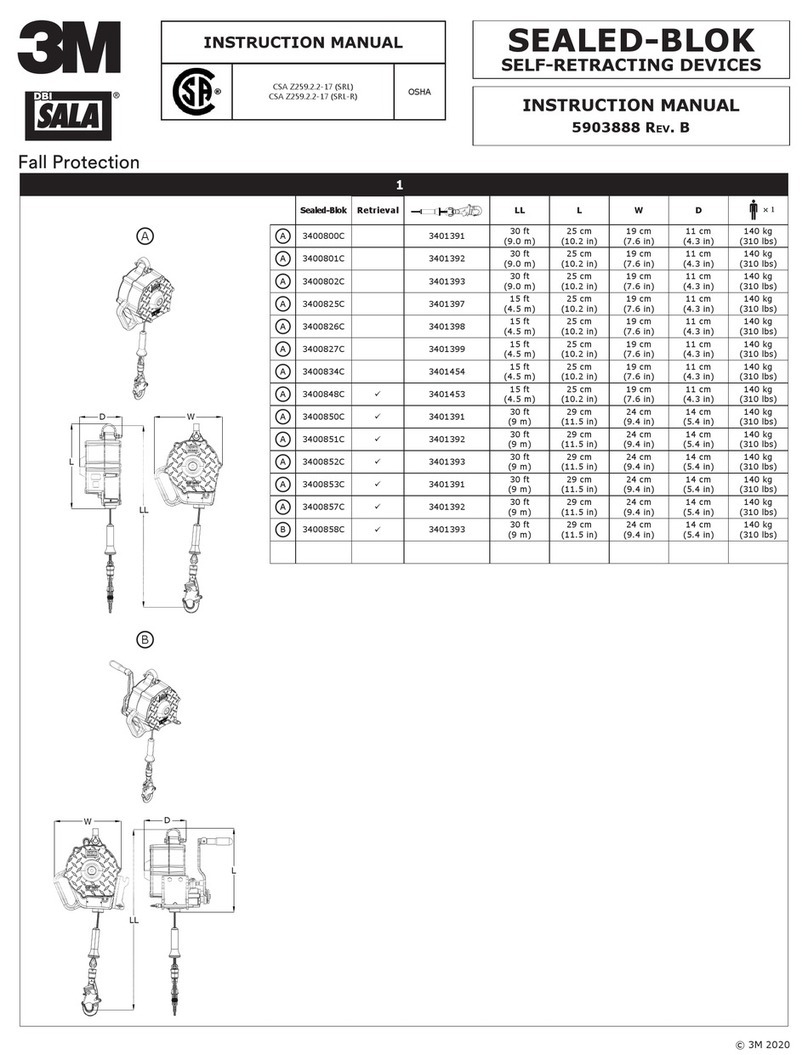

1.1 PURPOSE: Rope Grabs are designed to be a component in a Fall Arrest1or Fall Restraint2system. See Figure 9 for system

applications. Figure 9.1 shows a typical Fall Arrest System and gure 9.2 shows a typical fall restraint system. Each

system should contain a full body harness (E) connected to a lanyard (D or F). The lanyard is connected to the Rope Grab

(A), which is installed on a vertical lifeline (B) connected to an anchorage connector (C). An Energy Absorbing Lanyard (D)

must be used in a fall arrest system and a Restraint Lanyard (F) must be used in a fall restraint system.

1.2 STANDARDS: Your Rope Grab conforms to the national or regional standard(s) identied on the front cover of these

instructions. If this product is resold outside the original country of destination, the re-seller must provide these

instructions in the language of the country in which the product will be used.

1.3 TRAINING: This equipment must be installed and used by persons trained in its correct application. This manual is to

be used as part of an employee training program as required by ANSI and OSHA, and/or regional regulations. It is the

responsibility of the users and installers of this equipment to ensure they are familiar with these instructions, trained in

the correct care and use of this equipment, and are aware of the operating characteristics, application limitations, and

consequences of improper use of this equipment.

1.4 RESCUE PLAN: When using this equipment and connecting subsystem(s), the employer must have a rescue plan and

the means at hand to implement and communicate that plan to users, authorized persons3, and rescuers4. A trained, on-

site rescue team is recommended. Team members should be provided with the equipment and techniques to perform a

successful rescue. Training should be provided on a periodic basis to ensure rescuer prociency.

1.5 AFTER A FALL: If the Rope Grab or its attaching lanyard or vertical lifeline are subjected to the forces of arresting a fall,

it must be removed from service immediately and destroyed. Do not attempt maintenance or repair.

2.0 SYSTEM REQUIREMENTS

2.1 ANCHORAGE: Anchorage structure requirements vary with the system application and whether it is a certied anchorage5

or non-certied anchorage6. The structure to which a fall arrest, restraint, positioning, or rescue system is attached must

sustain static loads applied in the directions permitted as shown in the following table. Anchorage Strength requirements,

along with system applications, are specied below, unless noted or dened otherwise in Table 1:

Fall Protection System Certied Anchorage Non-Certied Anchorage Dened by

Fall Arrest 2 times maximum arresting force 5,000 lbs (22.2 kN) OSHA, ANSI

Restraint/Travel Restraint 2 times foreseeable force 1,000 lbs (4.4 kN) per ANSI

5,000 lbs (22.2 kN) per OSHA OSHA, ANSI

Work Positioning 2 times foreseeable force 3,000 lbs (13.3 kN) OSHA, ANSI

Rescue 5 times applied load 3,000 lbs (13.3 kN) ANSI

When more than one system is attached to an anchorage, the strengths stated above must be multiplied by the number

of systems attached to the anchorage. See ANSI Z359.2 for more information.

2.2 PERSONAL FALL ARREST SYSTEM: Figure 9 illustrates the application of this Rope Grab. The Personal Fall Arrest

System (PFAS) must meet applicable Fall Protection standards, codes, and requirements. The PFAS must incorporate a

Full Body Harness and limit Arresting Force to the following values:

Maximum Arresting Force Free Fall

PFAS with Energy-Absorbing Lanyard 1800 lbs (8 kN) 6 ft. (1.82 m)

2.3 LANYARDS: Refer to the instruction(s) included with your Lanyard for limitations specic to Lanyard use. See Table 1

for limitations of Lanyard use specic to this Rope Grab. Do not lengthen Lanyards for use with this Rope Grab without

consulting 3M. All Lanyards must have a minimum breaking strength of 5,000 lbs (22.2 kN).

2.4 HAZARDS: Use of this equipment in areas with environmental hazards may require additional precautions to prevent

injury to the user or damage to the equipment. Hazards may include, but are not limited to: heat, chemicals, corrosive

environments, high voltage power lines, explosive or toxic gases, moving machinery, sharp edges, or overhead materials

that may fall and contact the user or Personal Fall Arrest System.

2.5 FALL CLEARANCE: Figure 3 illustrates the components of a Fall Arrest system. There must be sufcient Fall Clearance

(FC) to arrest a fall before the user strikes the ground or other obstruction. Clearance is affected by a number of factors

including: Anchorage Location, (A) Lanyard Length, (B) Lanyard Deceleration Distance, (C) Harness Stretch, D-Ring/

Connector Length and Settling, (D) Rope Grab Lock-Up Distance, (E) Vertical Lifeline Length and Stretch, and (SF) Safety

Factor. Lanyard Length and Lanyard Deceleration Distance will vary with the Lanyard model.

Refer to Table 1 for details on Fall Clearance requirements. Figure 4 illustrates how positioning of the Rope Grab affects

the required Fall Clearance. Figure 5 gives the specic Fall Clearance value that is necessary, based on the exact

positioning of the Rope Grab. See Figure 4 and Figure 5 to determine Fall Clearance requirements. Fall Clearance values

include a Safety Factor of 1.5 ft and already account for stretch in the rope.

1 Fall Arrest System: A collection of Fall Protection Equipment congured to arrest a free fall. Protects the user in the event of a fall. Free fall is permitted up to

the limits allowed by the connecting device (for use with an Energy-Absorbing Lanyard only).

2 Restraint System: A collection of Fall Protection Equipment congured to prevent the person’s center of gravity from reaching a fall hazard. Prevents the user

from reaching a hazard. No vertical free fall is permitted.

3 Authorized Person: A person assigned by the employer to perform duties at a location where the person will be exposed to a fall hazard.

4 Rescuer: Person or persons other than the rescue subject acting to perform an assisted rescue by operation of a rescue system.