1.2 Packaging and Shipping, Receiving and Inspection, Handling

and Storage

1.2.1 Packaging and Shipping: Unless otherwise defined in the

purchase order and agreed byAAF, the FAH and filters are

packaged for domestic transit and shipped FOB theAAF factory.

The method of shipment will be as specified in the customers

purchase order toAAF.

1.2.2 Receiving and Inspection: Obtain a copy of the purchase

order, the product drawing that was submitted by AAF in

association with the order, and a copy of the bill of lading, along

with any other shipping papers. Upon receipt of the equipment, or

any part thereof, these documents shall be used to ensure that the

correct product has been received.

For maximum protection, complete the following steps upon receipt

of the FAH filter bank and filters:

— Inspect the shipment and all associated documentation. Notify

the carrier immediately if there is any visible damage to the

packaging or the equipment, or a discrepancy in the shipping

papers and, if necessary, file an immediate claim with the carrier

against such damage or discrepancy.

— Confirm that the equipment received agrees with the contents

of the shipping papers.

— Confirm that the shipping documents agree with the purchase

order. Refer to the product drawing submitted for the order as

necessary.

— If it is determined that any equipment ordered on the purchase

order has not been delivered and is not accounted for in the

shipping papers contactAAF international immediately by calling

1-800-477-1214. Reference theAAF control number which will

be listed on the shipping papers.

Each shipment may include:

— Individually packaged FrontAccess Housings.

— Packaged particulate filters.

— Packaged gas phase chemical filter cassettes.

Note that the housings and the particulate and gas phase filters

may ship from different locations and be received at different times.

1.2.3 Handling and Storage: Following receipt, inspection, and

acceptance of the equipment, and prior to assembly and installation,

the FAH and the particulate and gas phase filters shall be handled

with great care. The components shall be retained and stored in their

protective packaging until immediately prior to installation. Care shall

be taken to ensure that the packages are not dropped or subjected to

any impact loads.

At all times the equipment shall be protected from exposure to weather.

The equipment shall be stored in a clean, dry, temperature controlled

environment.All items shall be stored on pallets so that they are

elevated above grade. The FrontAccess Housings and particulate and

gas phase filters shall not be stacked more than three (3) cartons high

to prevent crushing. Only FAH shall be stacked on FAH, particulate

filters on particulate filters, and gas phase filters on gas phase filters.

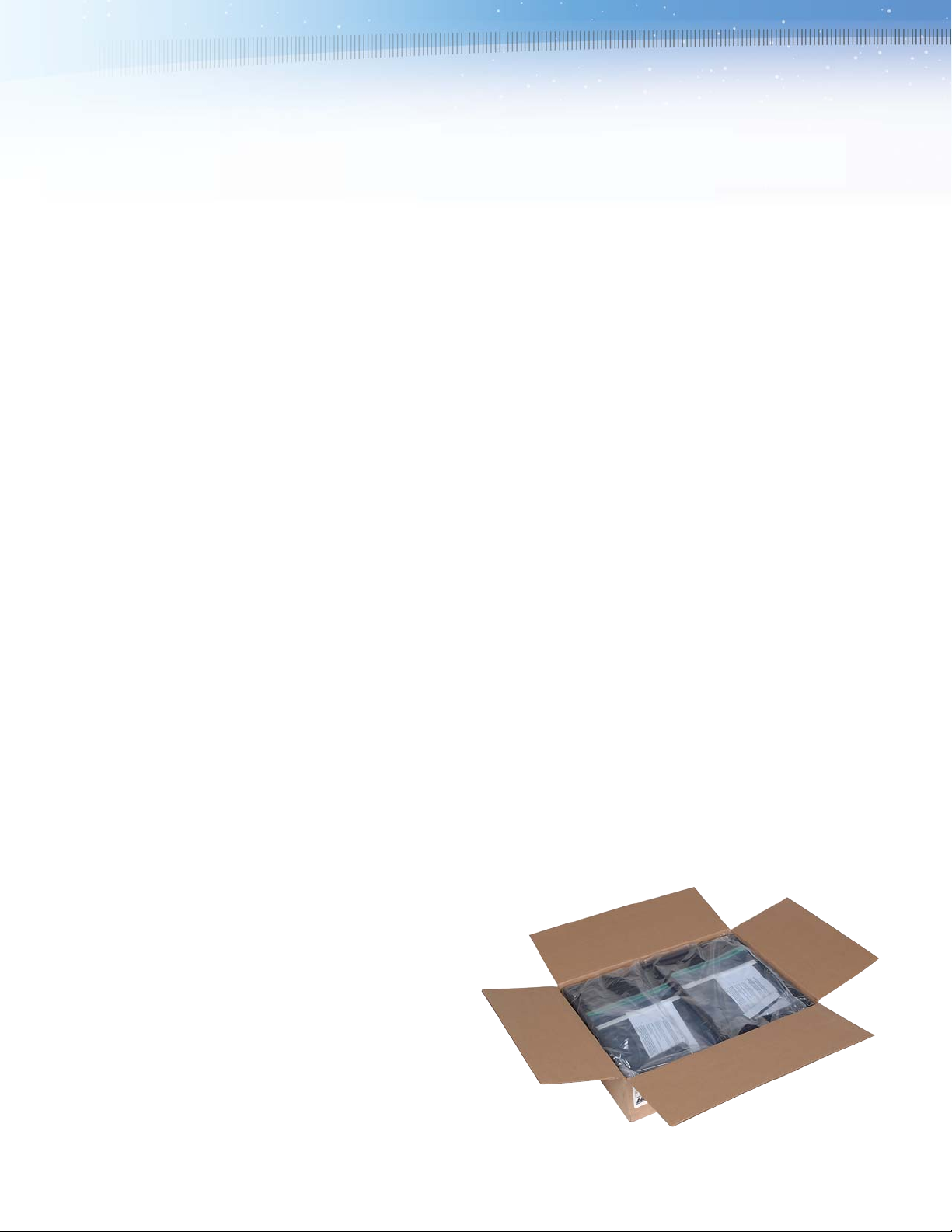

The gas phase filters ship inside a carton enclosed in transparent

protective plastic. Under no circumstances shall the filters be removed

from this plastic protection until immediately prior to installation.

Filter products shall not be stored in areas where they may become

contaminated by chemicals, either acids or alkalis, in liquid, vapor, or

gaseous form.

1.3 Product Descriptions

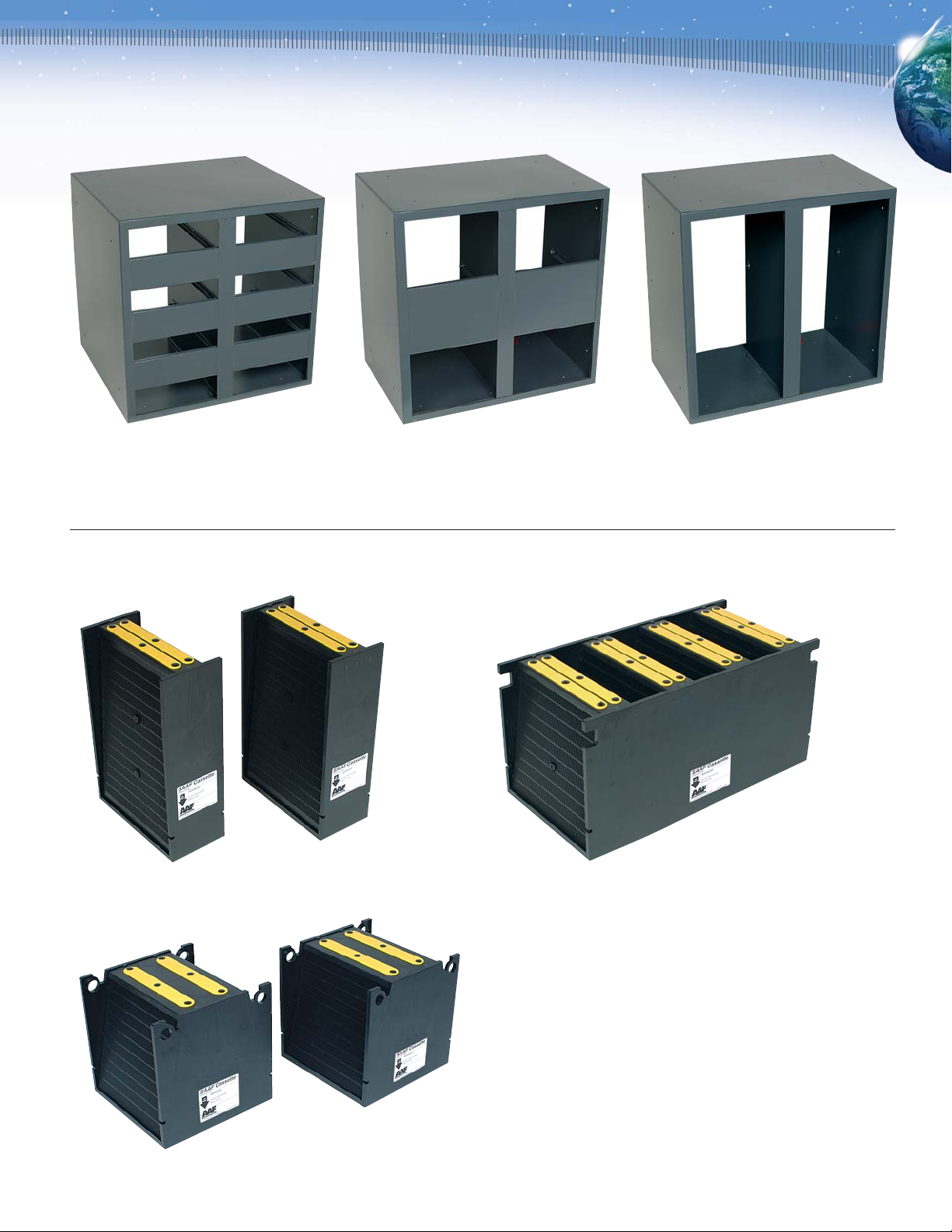

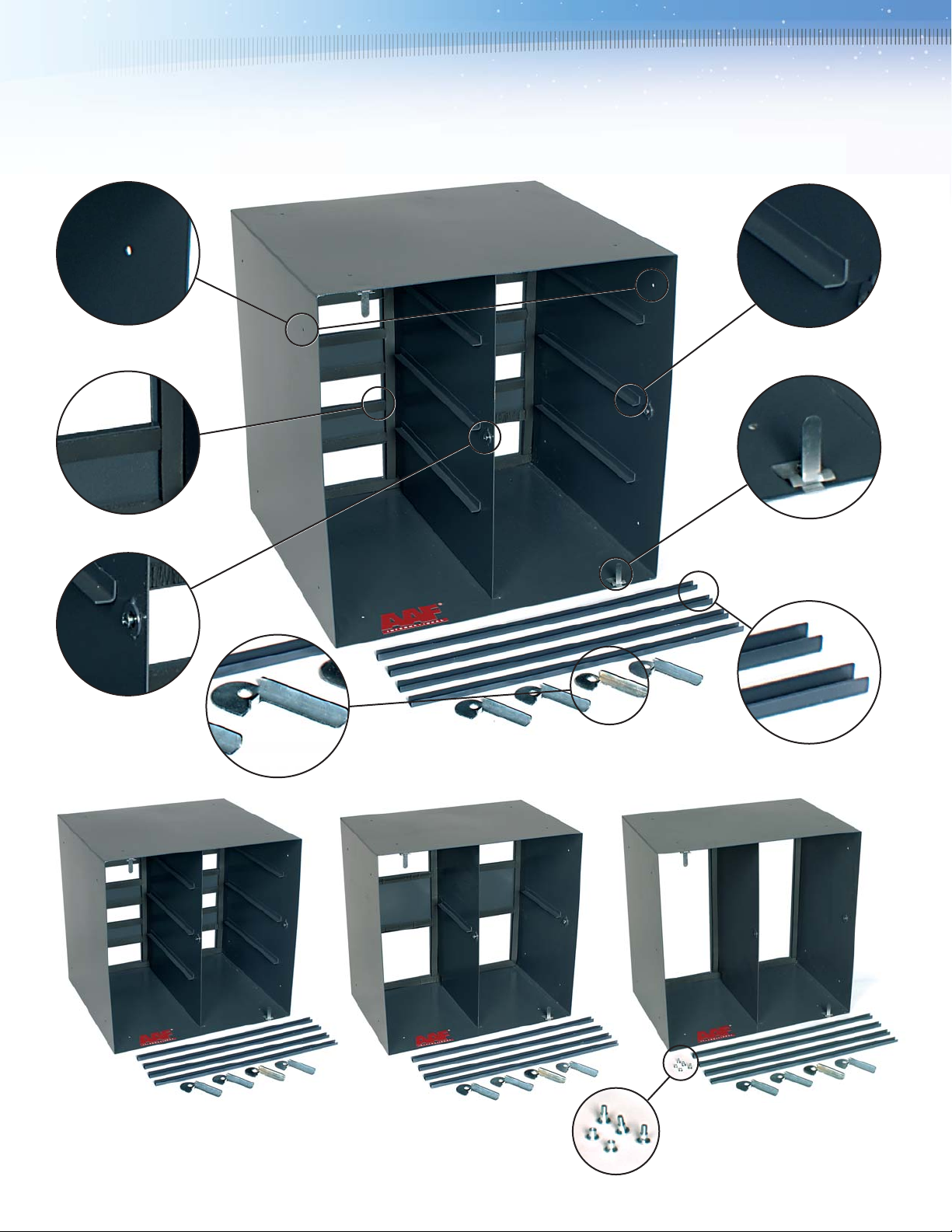

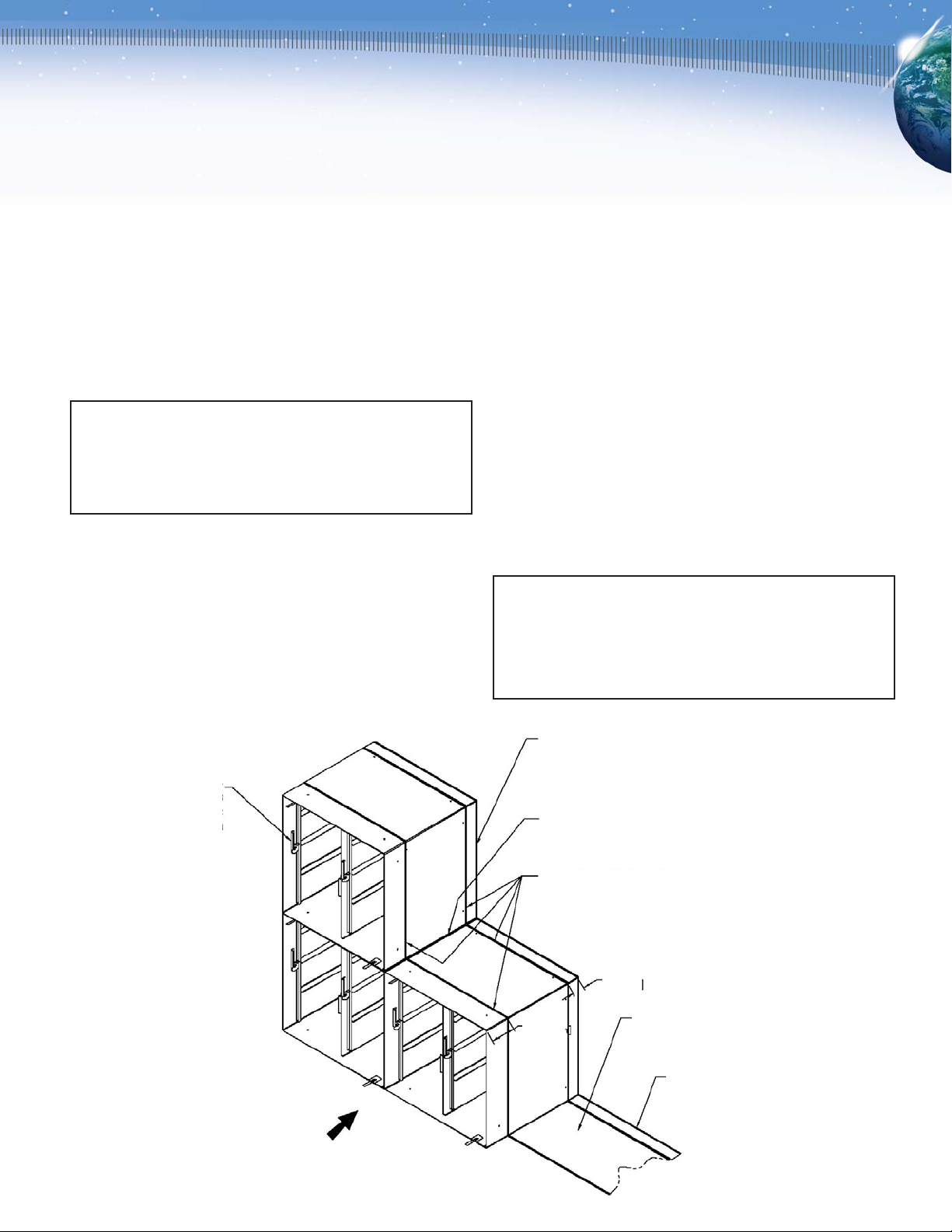

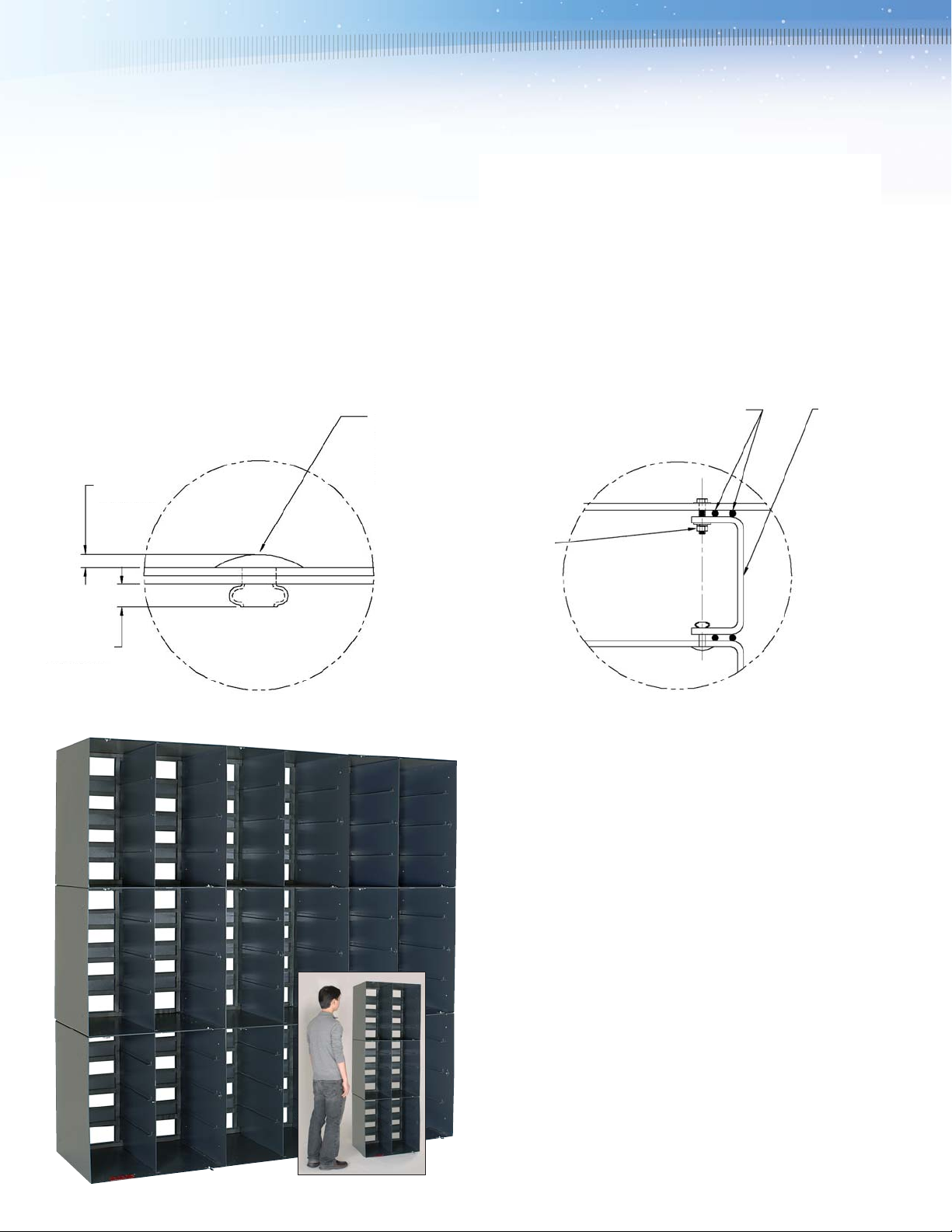

1.3.1 Front Access Housing (FAH): Each FAH will be received

individually in a carton. Depending on the quantity supplied, these

cartons may be palletized and banded together. The FAH is supplied

in three styles: Type MD, Type HD, or Type CG (as shown at top of

page 3) and will be the full size 2 high x 2wide housings shown, or

depending on the size of the filter bank required, may include half

size housings. Half size housings are available in half height (1 high

x 2wide) or half width (2high x 1 wide) sizes, except for the Type

CG which is only provided in the half width size. Half size housings

hold half the number of gas phase cassettes as full size housings

and use half size particulate filters.

Any particular filter bank will be assembled using only one type of

housing (Type MD, Type HD or Type CG). Housing types will never

be mixed in a single filter bank.

1.3.2 Gas Phase Chemical Filter Cassettes: Gas phase filter

cassettes are shipped in cartons and plastic bags. The carton

shown contains a single 6 high x 24 wide x 18 deep Type MD

cassette which is supplied as two (2) 6 high x 12 wide x 18 deep

half cassettes.

2