ABB ControlMaster CM10 Training manual

Other ABB Controllers manuals

ABB

ABB Welcome M2300 User manual

ABB

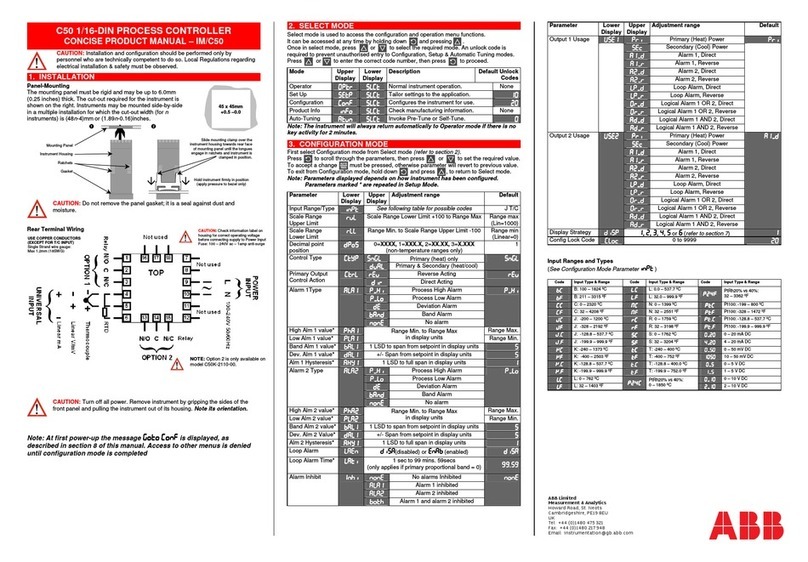

ABB C50 User manual

ABB

ABB COMMANDER 310 User manual

ABB

ABB COM600 series User manual

ABB

ABB ACS 501 Installation and operation manual

ABB

ABB TZIDC-110 User manual

ABB

ABB M10 Series User manual

ABB

ABB i-bus KNX User manual

ABB

ABB Relion RER615 User manual

ABB

ABB MotiFlex e180 User manual

ABB

ABB TCC300 User manual

ABB

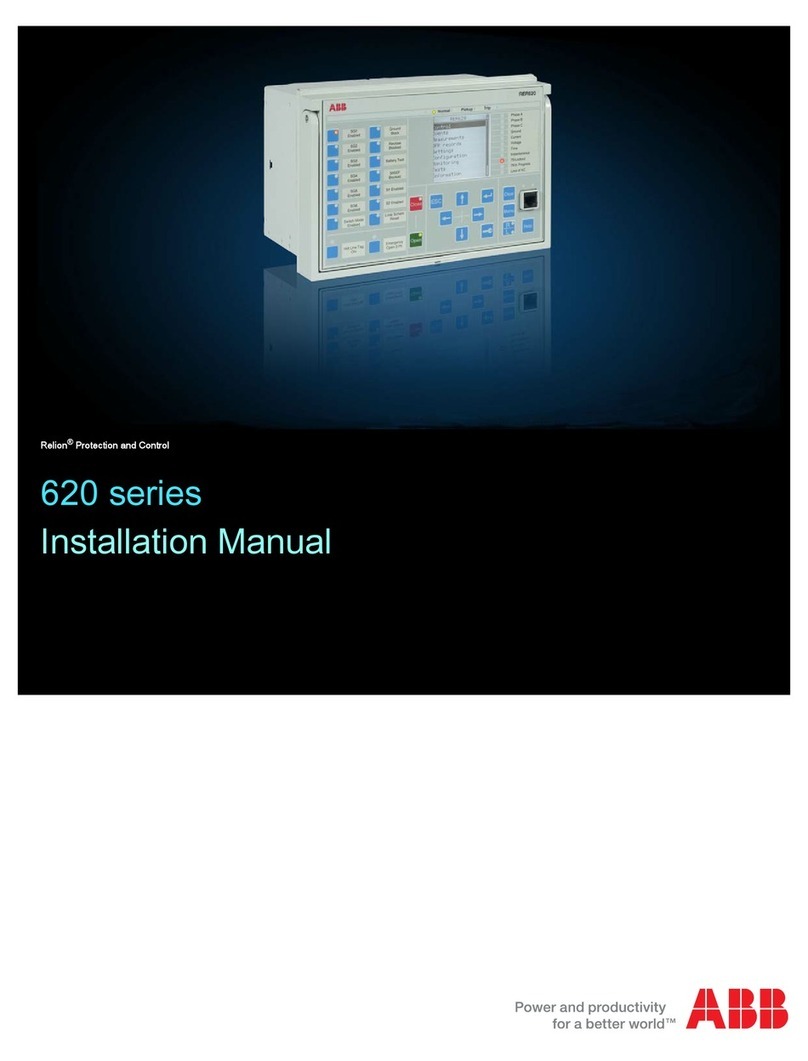

ABB Relion 620 Series User manual

ABB

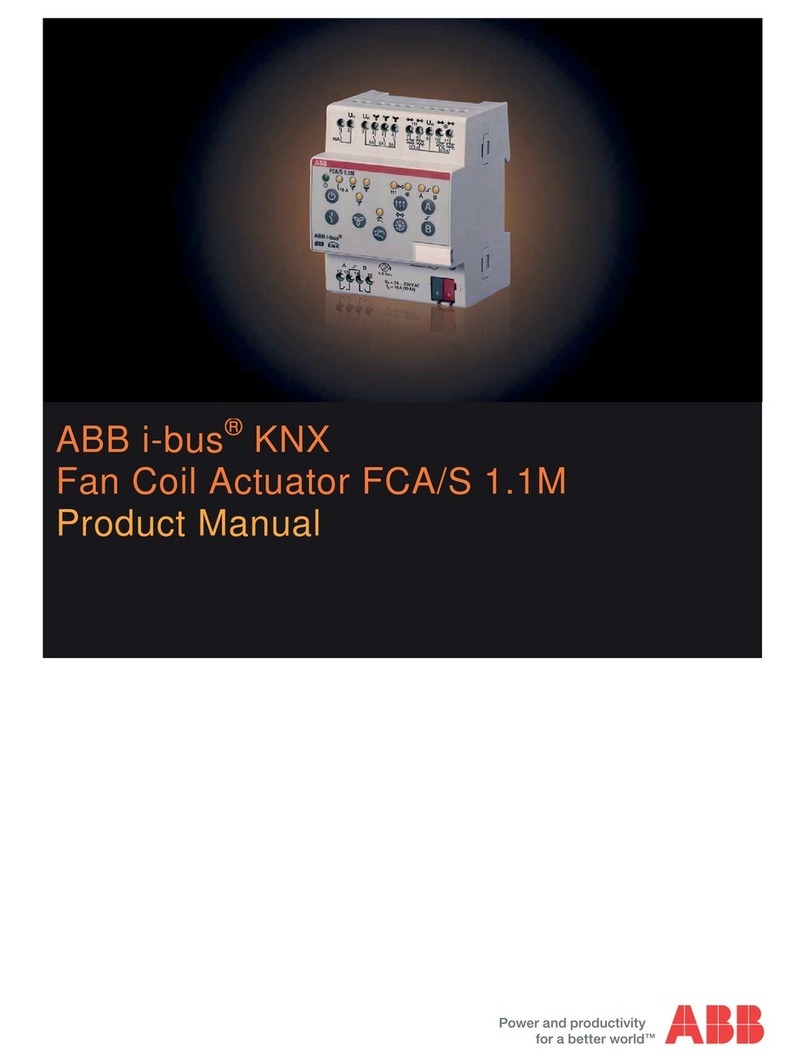

ABB i-bus KNX FCA/S 1.1M User manual

ABB

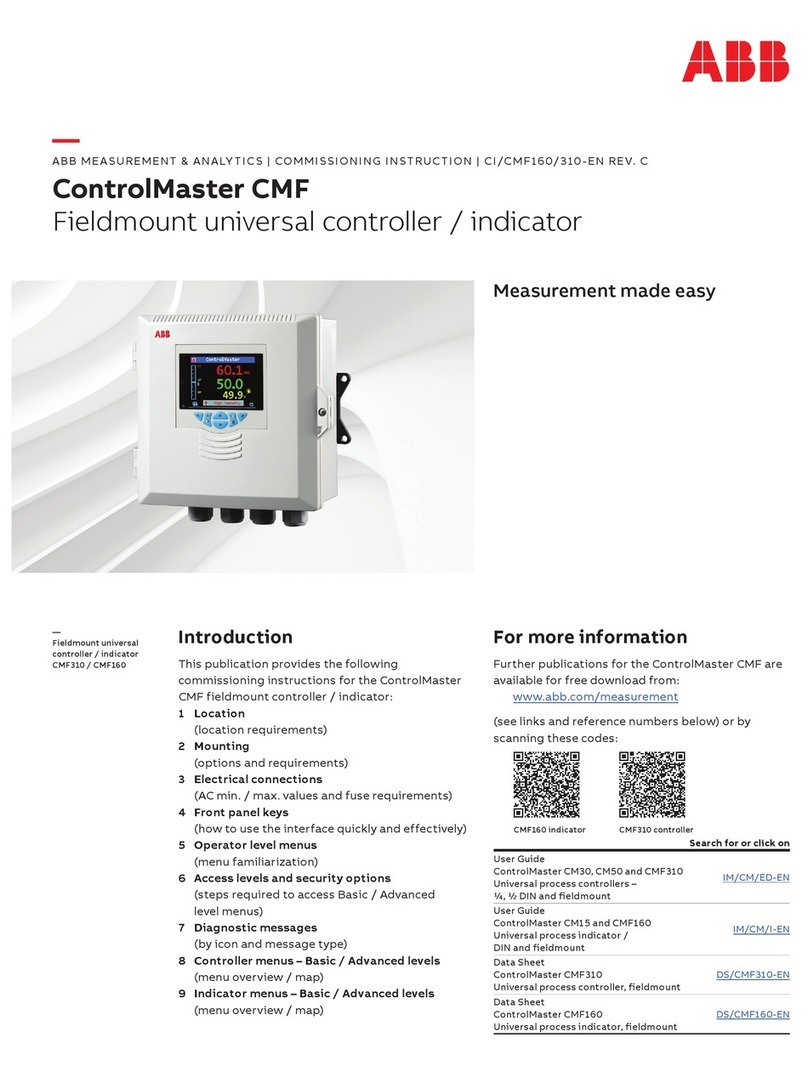

ABB ControlMaster CMF User manual

ABB

ABB ControlMaster CM30 User manual

ABB

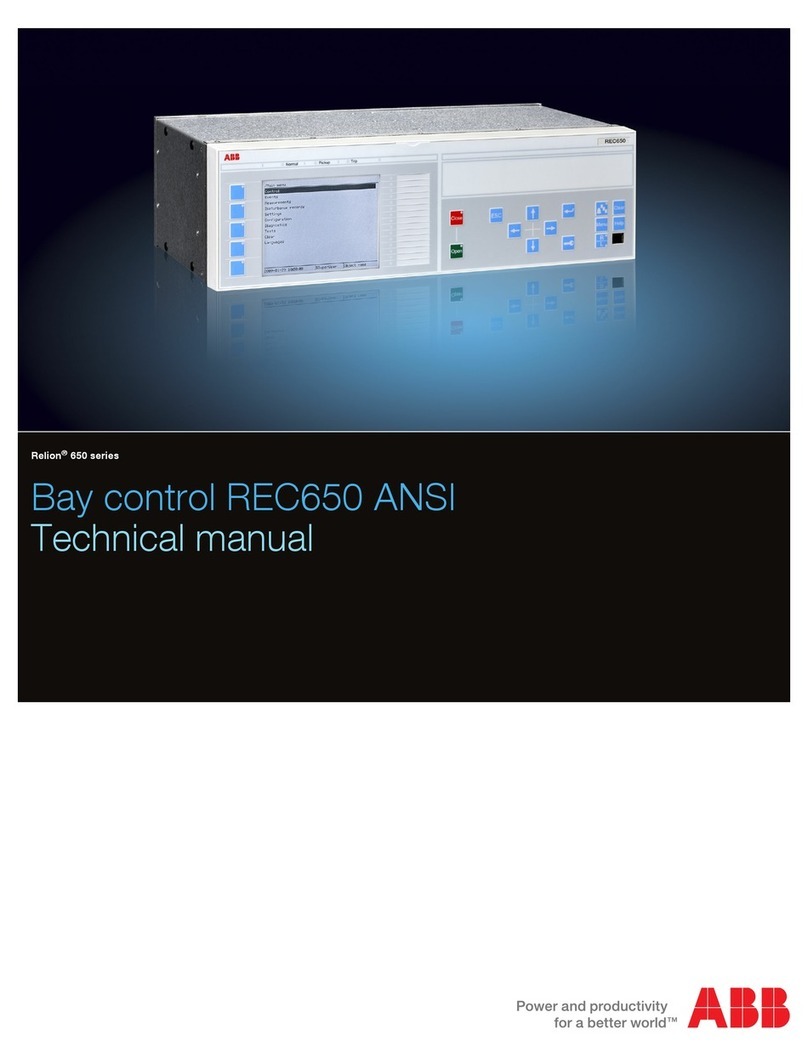

ABB REC650 ANSI User manual

ABB

ABB CBT-STAT User manual

ABB

ABB ACS 6000 Quick start guide

ABB

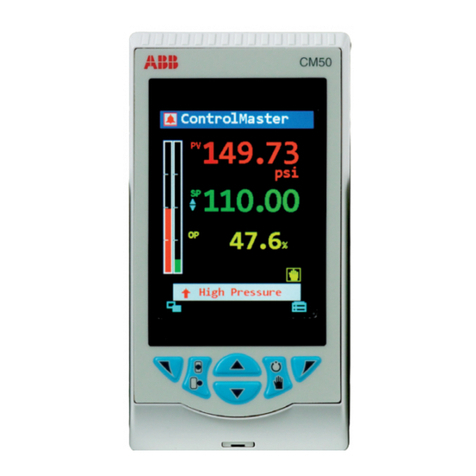

ABB ControlMaster Series User manual

ABB

ABB GPS2436 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions