Safety

—

—

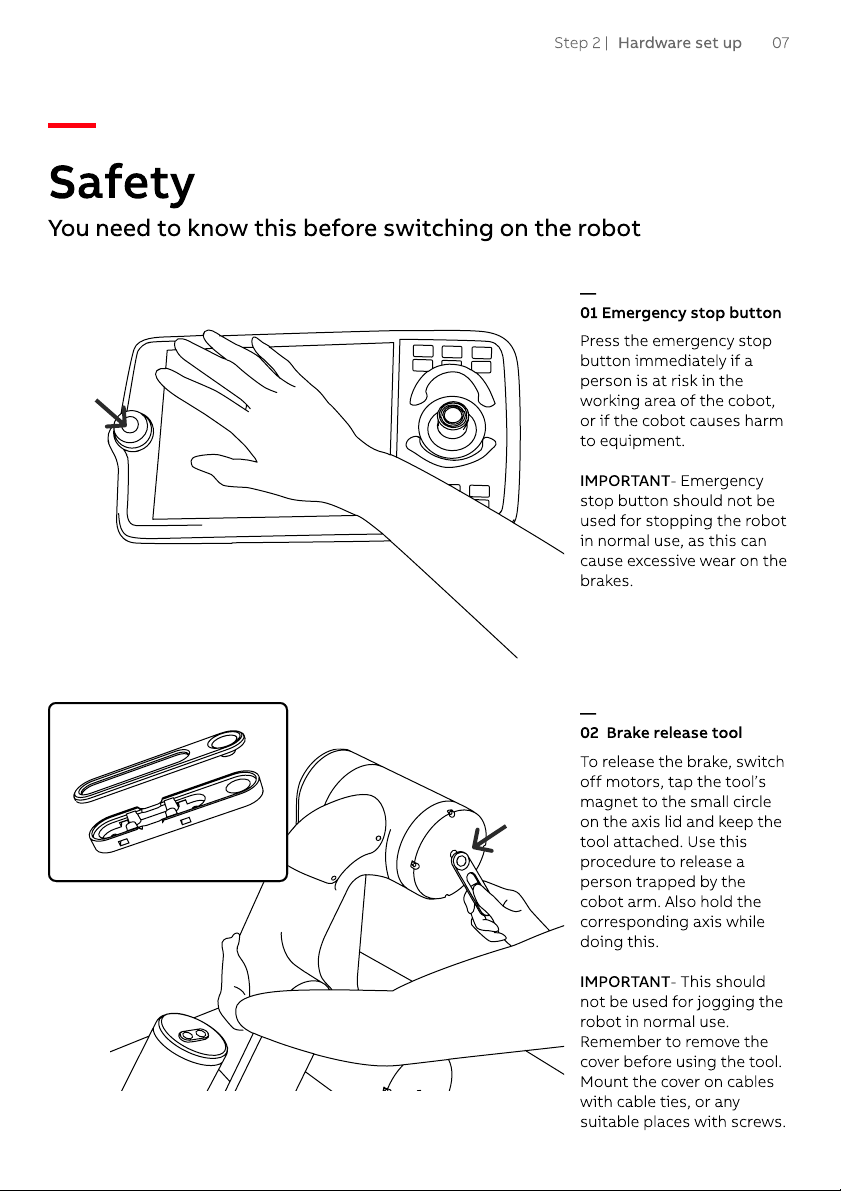

01 Emergency stop button

Press the emergency stop

button immediately if a

person is at risk in the

working area of the cobot,

or if the cobot causes harm

to equipment.

I PORTANT- Emergency

stop button should not be

used for stopping the robot

in normal use, as this can

cause excessive wear on the

brakes.

—

02 Brake release tool

To release the brake, switch

off motors, tap the tool’s

magnet to the small circle

on the axis lid and keep the

tool attached. Use this

procedure to release a

person trapped by the

cobot arm. Also hold the

corresponding axis while

doing this

I PORTANT- This should

not be used for jogging the

robot in normal use.

Remember to remove the

cover before using the tool.

Mount the cover on cables

with cable ties, or any

suitable places with screws.

07Step 2 | Hardware set up

You need to know this before switching on the robot