4EMAX LINK 2 ABBREVIATED LV SWITCHGEAR APPLICATION GUIDE

ABB Emax Link 2 Abbreviated Low Voltage

Switchgear is manufactured with rugged 12-gauge

steel and electrodeposition coated gray paint to

stand up to normal industrial environments. The

switchgear is compartmentally designed to enclose

all electrical parts. Emax Link 2 is UL Recognized to

UL 1558 and is designed, manufactured, and tested

in accordance with ANSI/ IEEE C37.20.1 and C37.51.

Front and rear doors/panels and doors are

manufactured in 12-gauge and 14-gauge steel

NEMA Type 1 ratings as standard.

All sections include a top and a bottom horizontal

wireway for control wiring.

Units feature front, hinged doors held closed by

one or more latches.

The rear door is secured by a swing handle with a

door-lock mechanism that secures the door at four

points of contact. A bolted rear cover is optional.

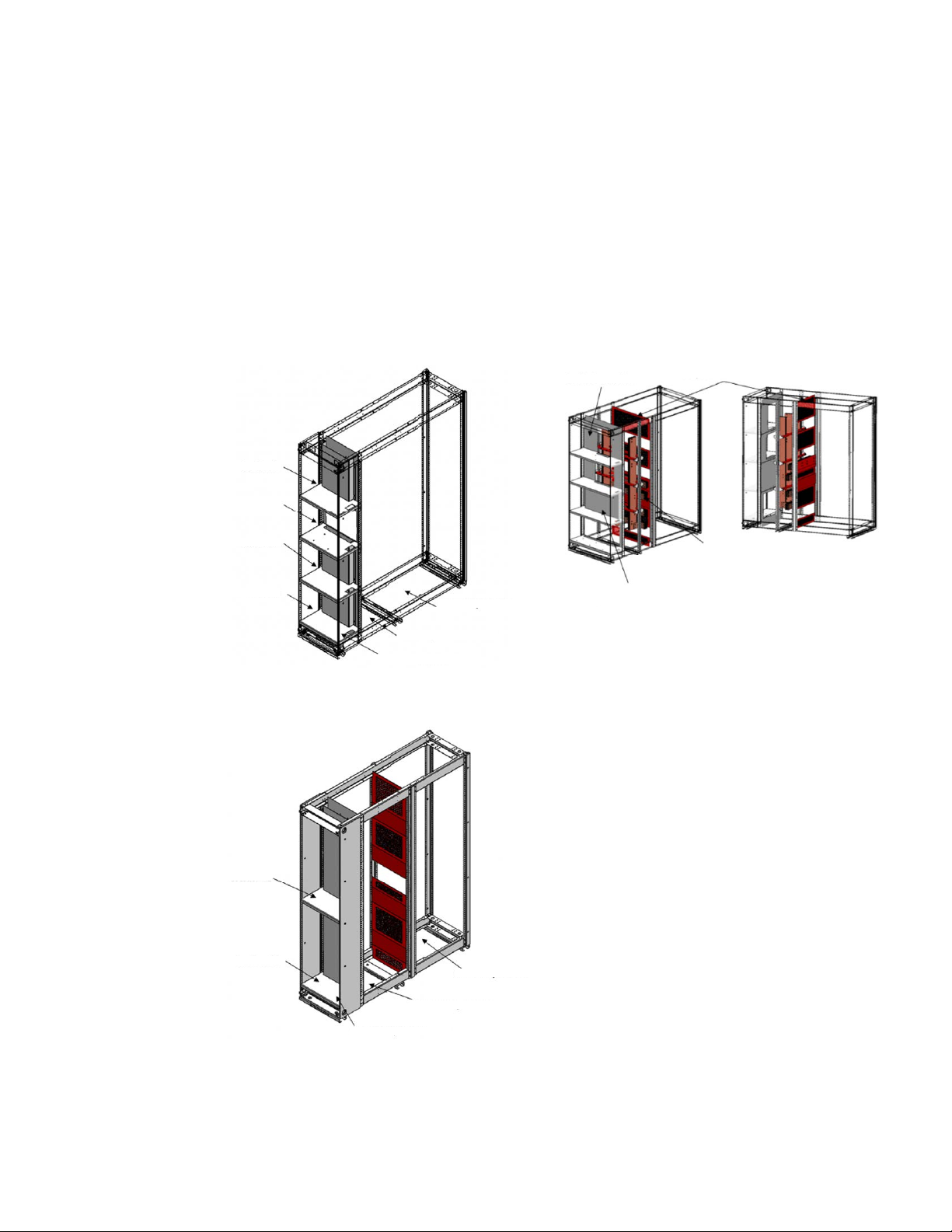

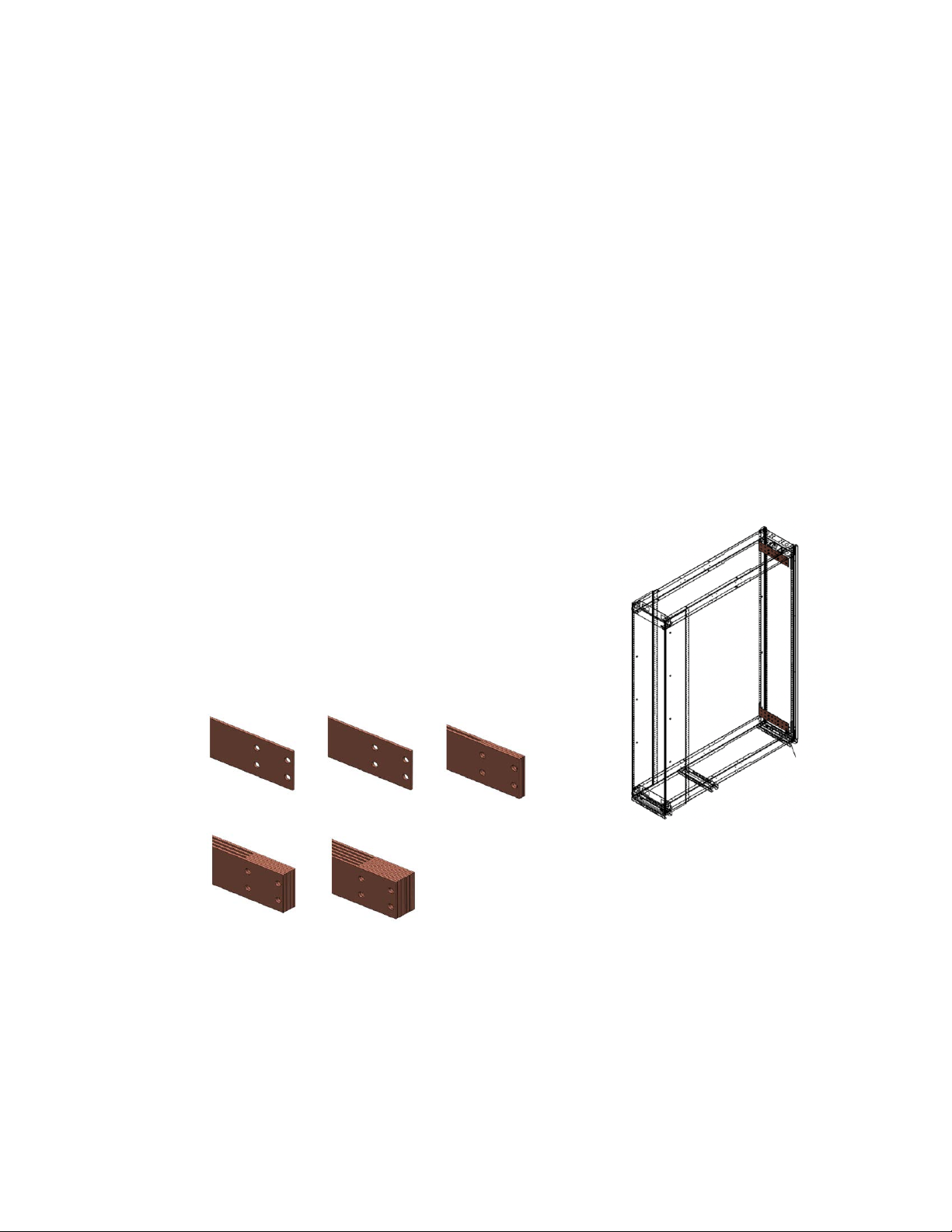

The switchgear assembly consists of one or more

metal-enclosed vertical sections joined side-by-

side with a horizontal bus. Each vertical section is

an enclosed, vertical metal cabinet that contains

devices, wireways and other internal components.

Up to three vertical sections are arranged and

joined side-by-side at the factory. This facilitates

shipping, handling and installation. A lineup may

include more than one shipping split depending on

the configuration.

Each vertical section is divided into several areas:

The instrumentation/device compartment in the

front of the section, the bus compartment in the

middle and the cable compartment for the end

terminal connections at the back.

The front compartment within a section can be

divided into smaller modules to accommodate

devices of different heights. One section may be

divided into as many as four of these modules.

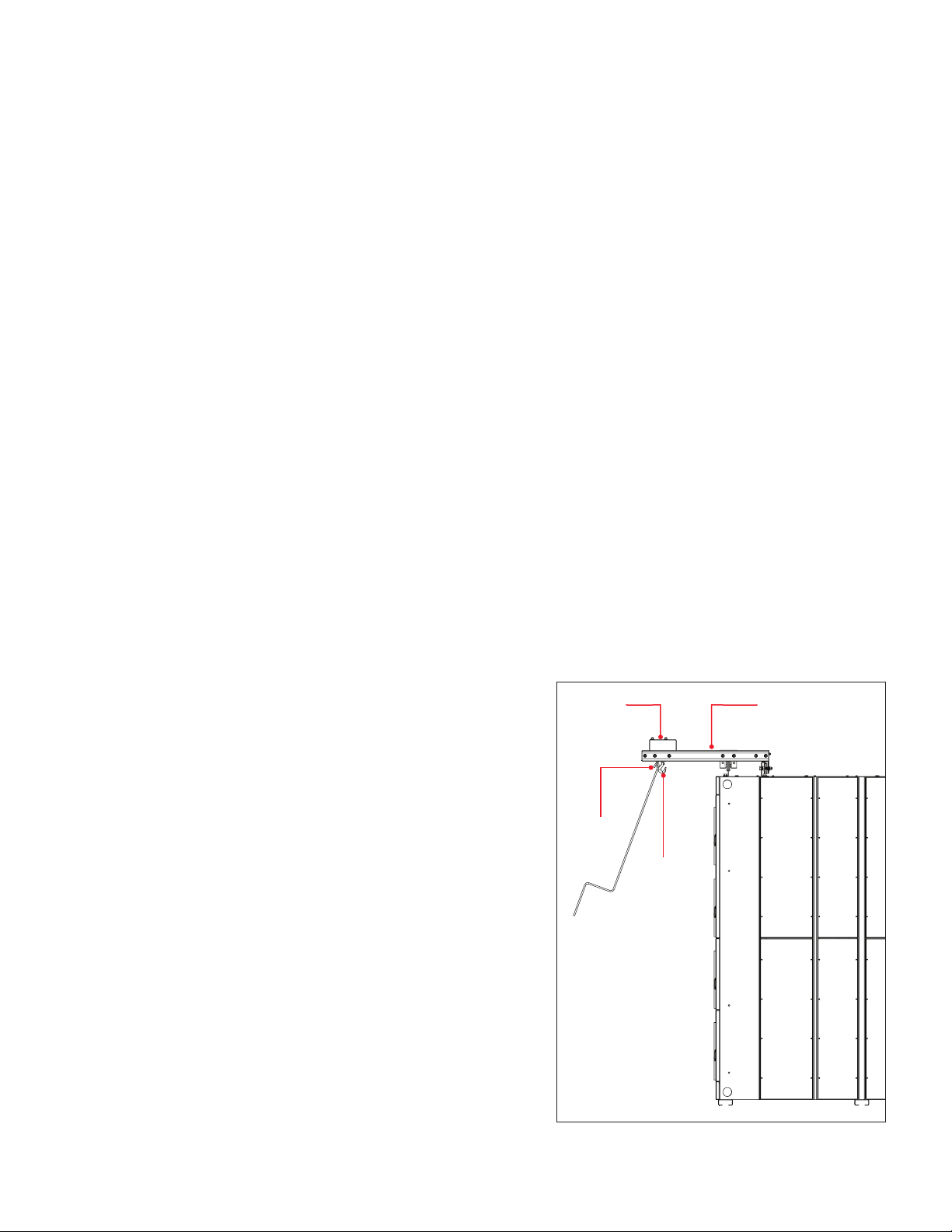

A traveling, overhead lifting device is available to

assist with handling breakers. The front section of

the switchgear provides support for the lifting

device. The device travels the full width of the

switchgear. Utilizing a lifting yoke, the breaker lifts

from a completely withdrawn circuit breaker cradle.

A worm-gear-driven mechanism and wire rope,

operated by a removable hand crank, provide

lifting power.

—

General description

Enter the ever-growing low voltage switchgear market without the high overhead

costs of labor, design and testing. The ABB Emax Link 2 UR 1558 structures provide a

turnkey solution for OEMs. Emax Link 2 combined with SACE®Emax 2 circuit breakers

provides advanced power distribution technology and helps enhance safety in a fast,

flexible and cost-effective solution for the OEM low voltage switchgear market.

Lifting

hook

Winch

hook

Carriage

assembly

Winch

mechanism