Operation Manual / TPL85-B14/-B15/-B16

Table of contents

© Copyright 2018 . All rights reserved. HZTL2491_EN Revision C August 2018

5.4 Cleaning the compressor during operation ............................................................ 53

5.5 Cleaning turbine blades and nozzle ring in operation........................................... 58

6 Troubleshooting..................................................................................................... 72

6.1 Malfunctions when starting........................................................................................ 72

6.2 Surging of the turbocharger....................................................................................... 73

6.3 Malfunctions during operation .................................................................................. 74

6.4 Malfunctions when stopping ...................................................................................... 77

6.5 Speed measurement system ...................................................................................... 78

7 Removal and installation...................................................................................... 79

7.1 Turbocharger weights.................................................................................................. 79

7.2 Removing the turbocharger........................................................................................ 79

7.3 Installing the turbocharger ......................................................................................... 81

8 Disassembly and assembly .................................................................................. 82

8.1 Introduction ................................................................................................................... 82

8.2 Module weights ............................................................................................................ 84

8.3 Silencer casing .............................................................................................................. 86

8.4 Removing and installing the filter silencer.............................................................. 90

8.5 Axial clearance ............................................................................................................... 92

8.6 Removing internal part of compressor casing........................................................ 93

8.7 Removing gas inlet casing........................................................................................... 97

8.8 Fitting gas inlet casing ............................................................................................... 99

8.9 Fitting internal part of compressor casing .......................................................... 100

8.10 Dry-cleaning device..................................................................................................... 103

8.11 Table of tightening torques..................................................................................... 106

9 Short-term turbocharger shut-down ............................................................... 108

9.1 Possibilities for emergency repair.......................................................................... 108

9.2 Locking the rotor......................................................................................................... 109

9.3 Shutting off inlets and outlets ................................................................................. 112

9.4 Bypass the turbocharger ........................................................................................... 113

10 Storing turbocharger........................................................................................... 114

10.1 Taking out of operation for up to 12 months........................................................ 114

10.2 Taking out of operation for more than 12 months............................................... 114

11 Disposing of turbocharger components........................................................... 116

12 Spare parts............................................................................................................ 117

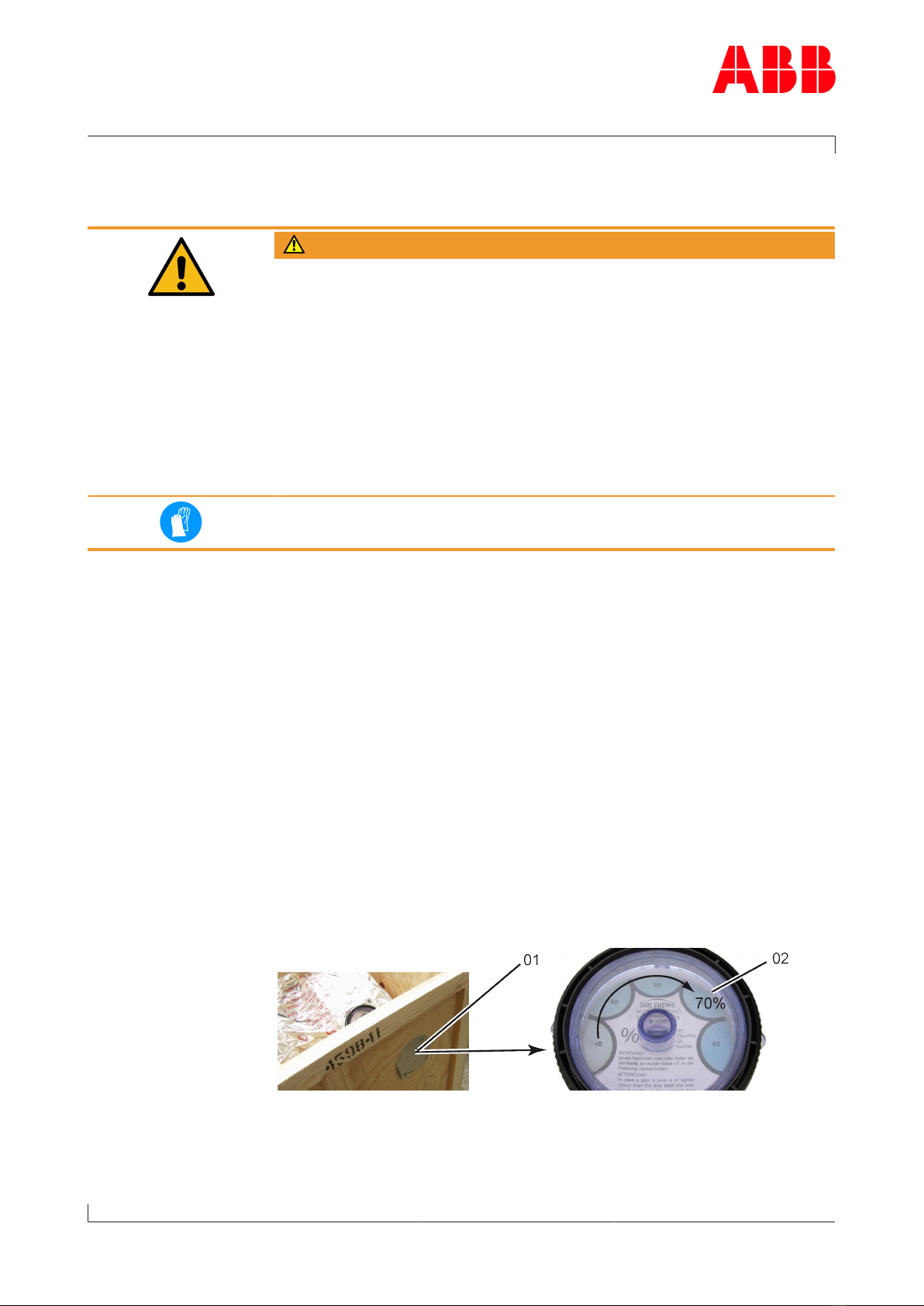

12.1 Ordering spare parts.................................................................................................. 117

12.2 View of turbocharger with part numbers .............................................................. 120

12.3 View of cartridge group with part numbers.......................................................... 122