1

This guide is applicable to the global product types. There is a separate guide for the North American product types.

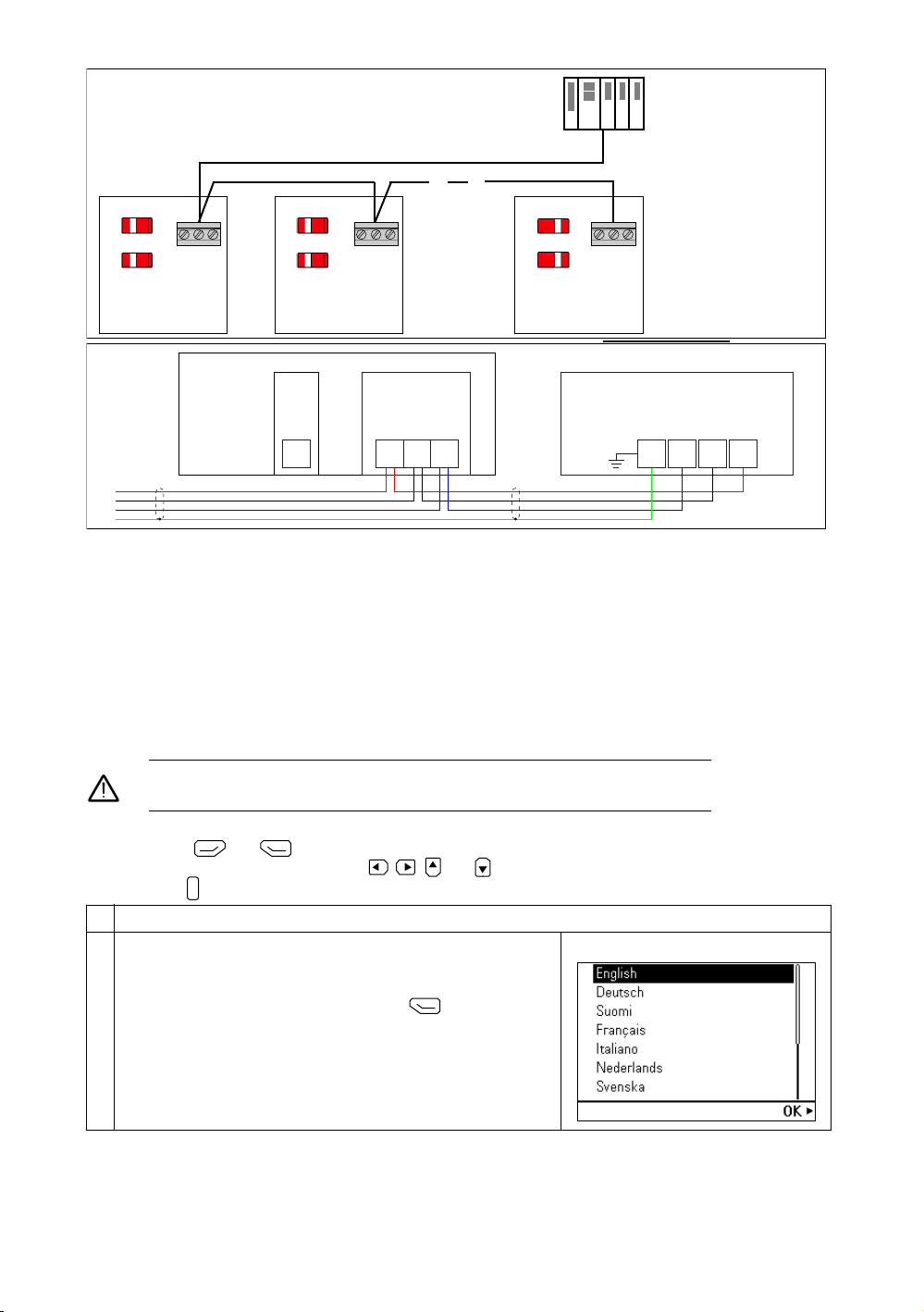

Safety instructions

WARNING! Obey these instructions. If you ignore them, injury or death, or damage to the equipment can occur. If

you are not a qualified electrical professional, do not do electrical installation or maintenance work.

WARNING! Before you activate the automatic fault reset or automatic restart functions of the drive control

program, make sure that no dangerous situations can occur. These functions reset the drive automatically and

continue operation after a fault or supply break. If these functions are activated, the installation must be clearly

marked as defined in IEC/EN/UL 61800-5-1, subclause 6.5.3, for example, “THIS MACHINE STARTS AUTOMATICALLY”.

•Do not do work on the drive, motor cable, motor, or control cables when the drive is connected to the input power.

Before you start the work, isolate the drive from all dangerous voltage sources and make sure that it is safe to start

the work. Always wait for 5 minutes after disconnecting the input power to let the intermediate circuit capacitors

discharge.

•Do not do work on the drive when a rotating permanent magnet motor is connected to it. A rotating permanent

magnet motor energizes the drive, including its input and output terminals.

•Do not tilt the drive. The drive is heavy and has a high

center of gravity. It can topple accidentally.

•All frames have lifting eyes to assist with lifting.

•Frames R3: Lifting the drive with a lifting device is

recommended since weight exceeds 50 lb (23 kg)

1. Unpack the drive

Keep the drive in its package until you are ready to install it.

Make sure that these items are included:

•drive

•mounting template

•control panel (factory-installed inside the cover)

•quick installation and start-up guide

•multilingual residual voltage warning stickers

•hardware and firmware manuals, if ordered

•options in separate packages, if ordered.

Make sure that there are no signs of damage to the items.

2. Reform the capacitors

If the drive has not been powered up for a year or more, you must reform the DC link capacitors. See Related documents or

contact ABB technical support.

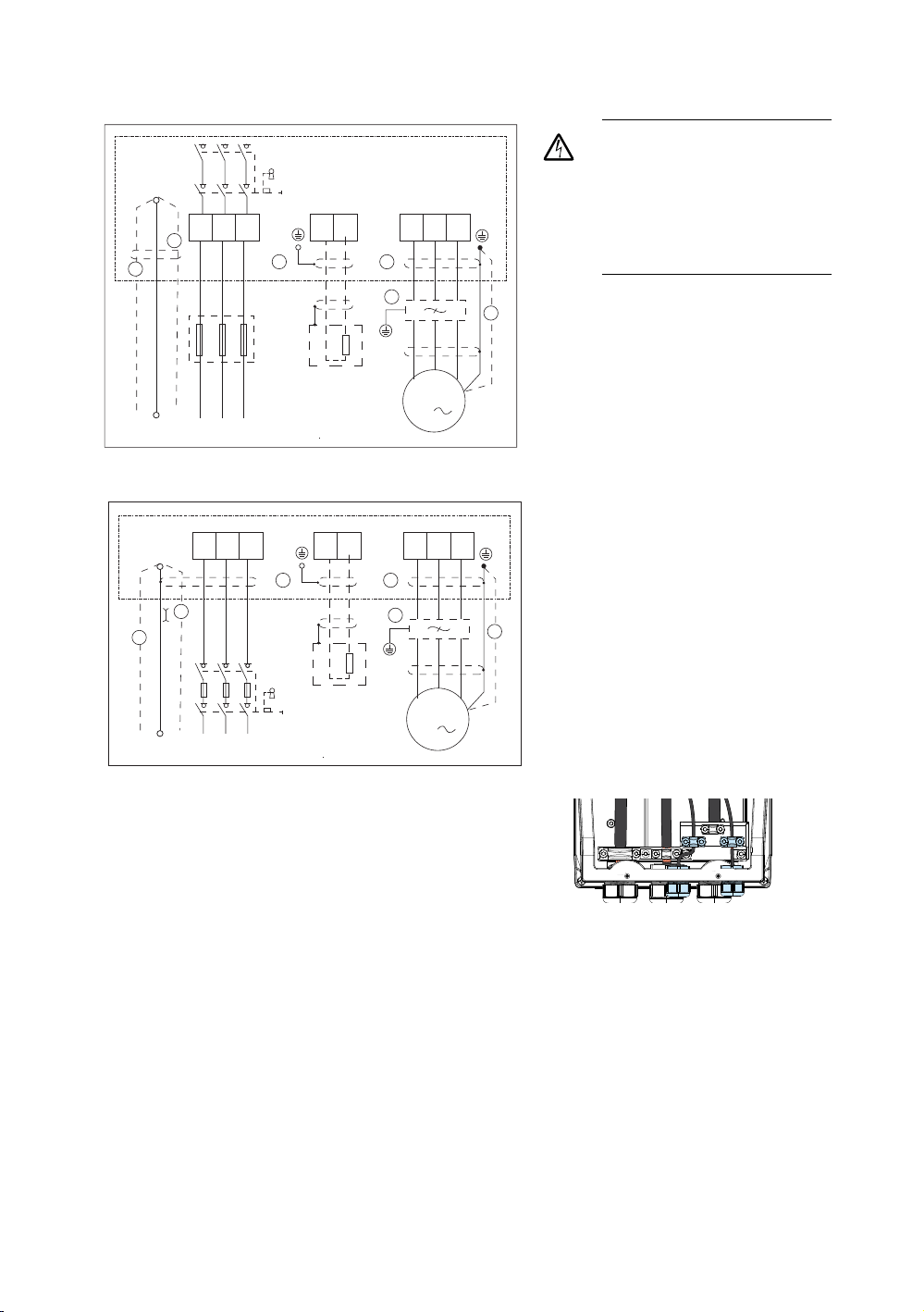

3. Select the cables and fuses

Obey the local regulations for the environment in which the drive will be installed.

Input power cable: Use symmetrical shielded cable (VFD cable) for the best EMC performance.

Motor cable: Use symmetrically shielded VFD motor cable to reduce bearing current and wear and stress on motor

insulation to provide the best EMC performance.

Documentation in other languages Ecodesign information

(EU 2019/1781 and SI 2021 No. 745) About this document

3AXD50001020170 Rev A EN

2023-07-10

© 2023 ABB. All rights reserved.

Original instructions.

—

DRIVES FOR WATER

ACQ580-01 IP66 (UL Type 4X) drives, IEC types

Quick installation and start-up guide