6PB/F - PB/FL type PowerCube - INSTALLATION AND SERVICE INSTRUCTIONS

—

4. Handling

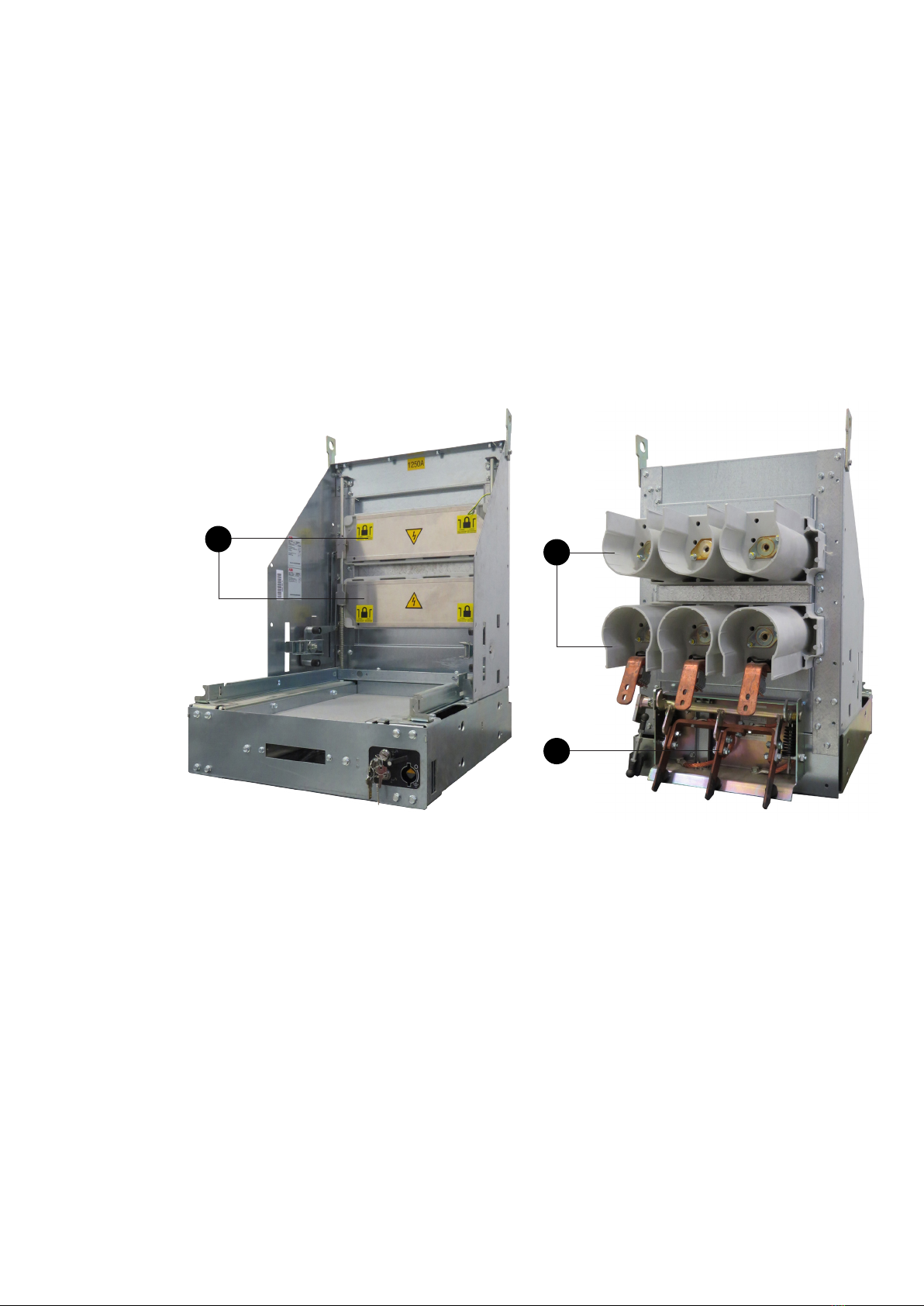

4.1. Fixed parts

Each fixed part is usually fixed onto a wooden

platform.

Handling should preferably be carried out by means

of bridge or mobile cranes. Otherwise, use rollers or

fork lift trucks.

Weights and dimensions of the various sections are

indicated in the shipping documents and on the plant

drawings.

Fixed parts handling

To handle the fixed parts containing the

apparatus (circuit breaker, contactor or

service truck), it is compulsory to use the

lifting eyebolts provided with the module.

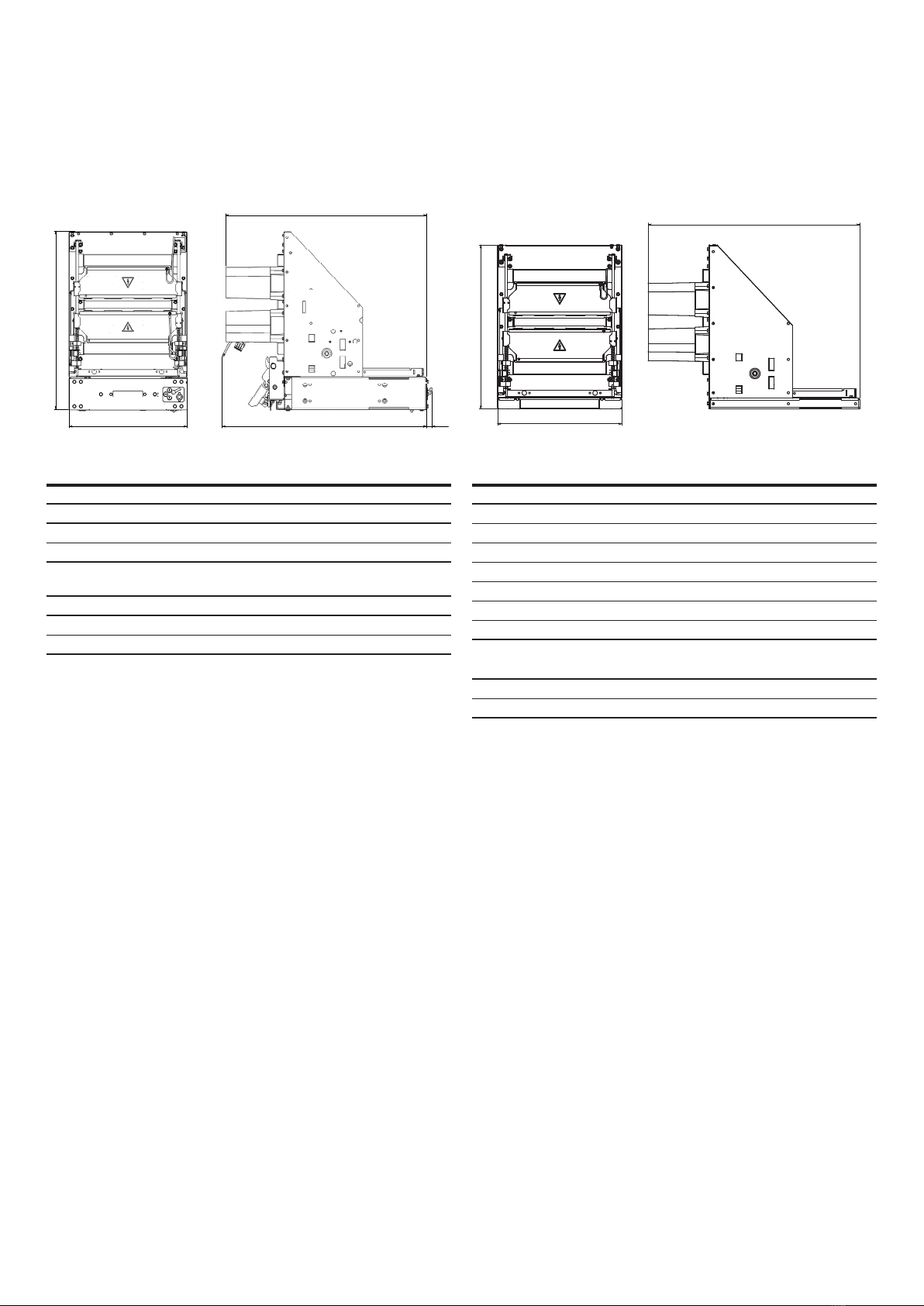

4.1.1. Handling with bridge or mobile crane and

unpacking

Handling the fixed part in the wood packing

Lifting by means of a crane must be carried out using

the circular slings (1) (fig. 2).

The slings must be inserted according to the lifting

symbols marked on the crate.

Weight and lifting opening angle must be taken into

account when choosing the circular slings.

Unpacking

• Remove the nails and crate lid and sides;

• loosen the screws fixing the fixed part to the pallet

(if present);

• lift the module by means of the crane;

• slide the pallet out from under the fixed part;

• position the unloading shims;

• lower the module onto the shims using the crane.

After unpacking it, lift the module by means of a

crane, using the special eyebolts (1) (fig. 3) and the

ropes fitted with safety spring catches.

After installation, remove the eyebolts (1).

4.1.2. Handling by means of transpallets or fork

lift trucks

fork lift trucks run must be completely

which might turn it over.

For greater stability, only lift the fixed part enough to

allow handling. Also check levelness of the forks.