2

1MRS 752014-MUM EN

Issued 2000-11-22

Version A (replaces 34 SACO 64 1 EN1)

Checked

Approved

Data subject to change without notice

SACO 64D4

Annunciator unit

Table of contents Features .......................................................................................................................... 3

General ........................................................................................................................... 3

Areas of appIication ........................................................................................................ 3

Ilustration of function .................................................................................................... 4

General system data ................................................................................................... 4

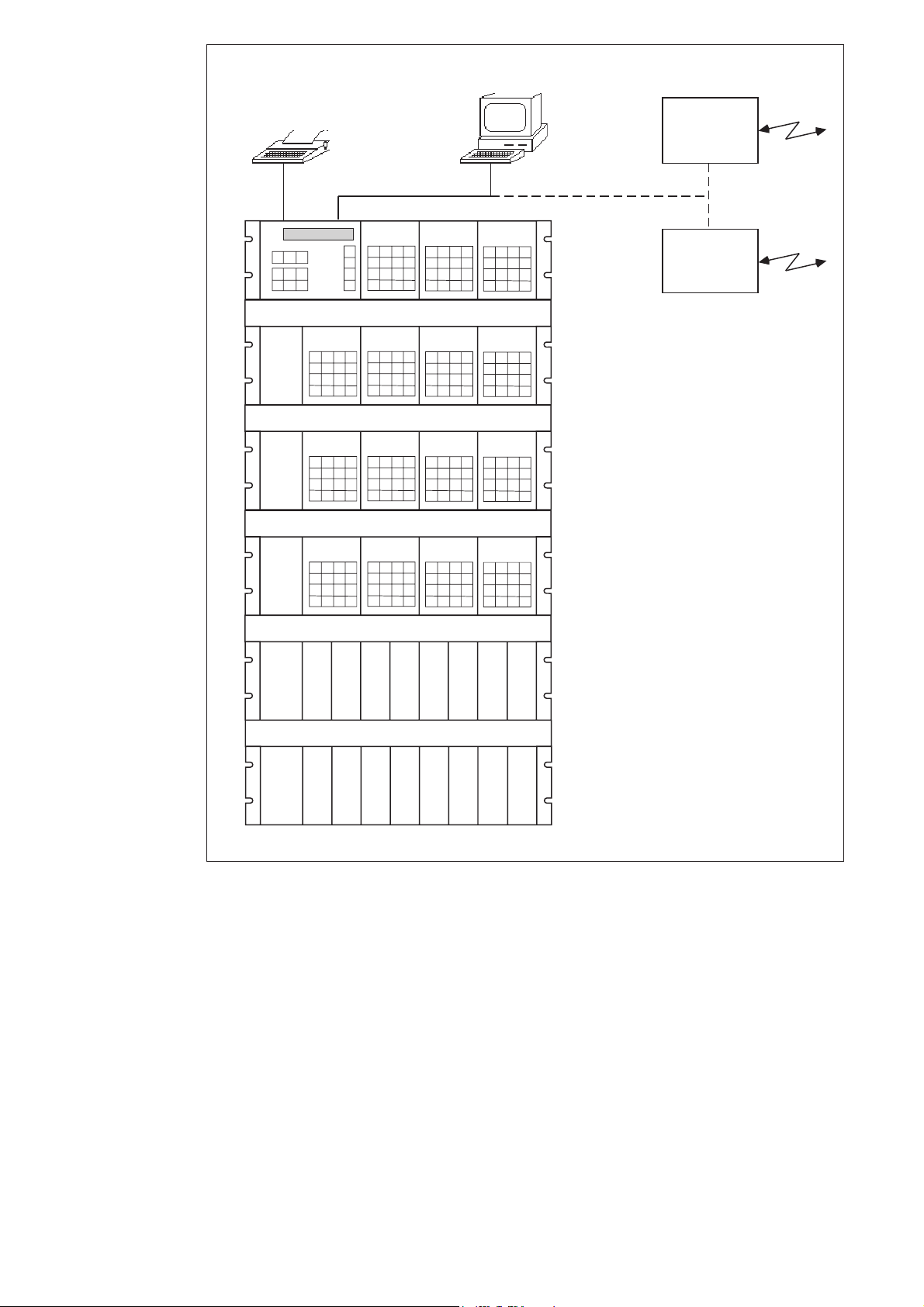

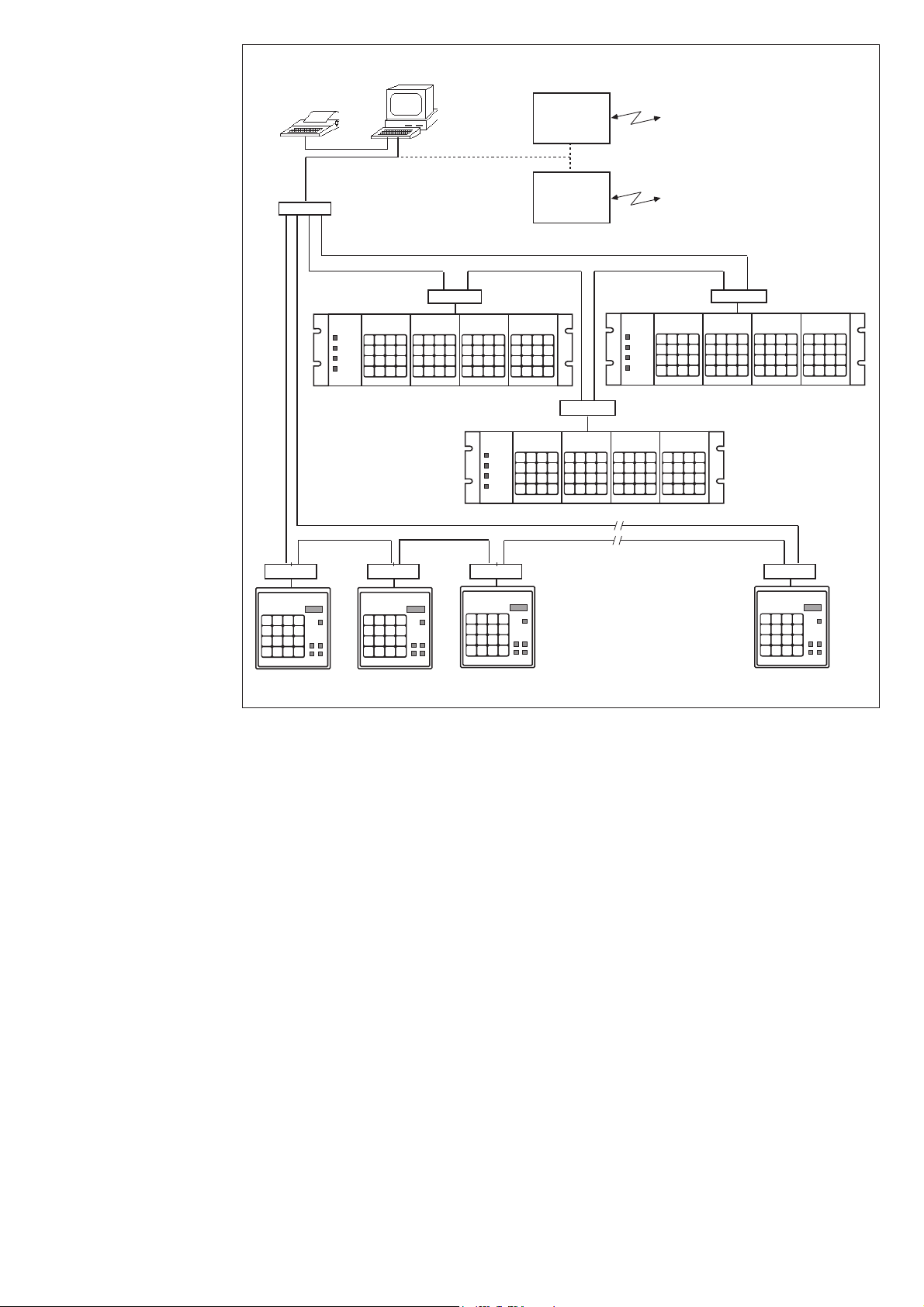

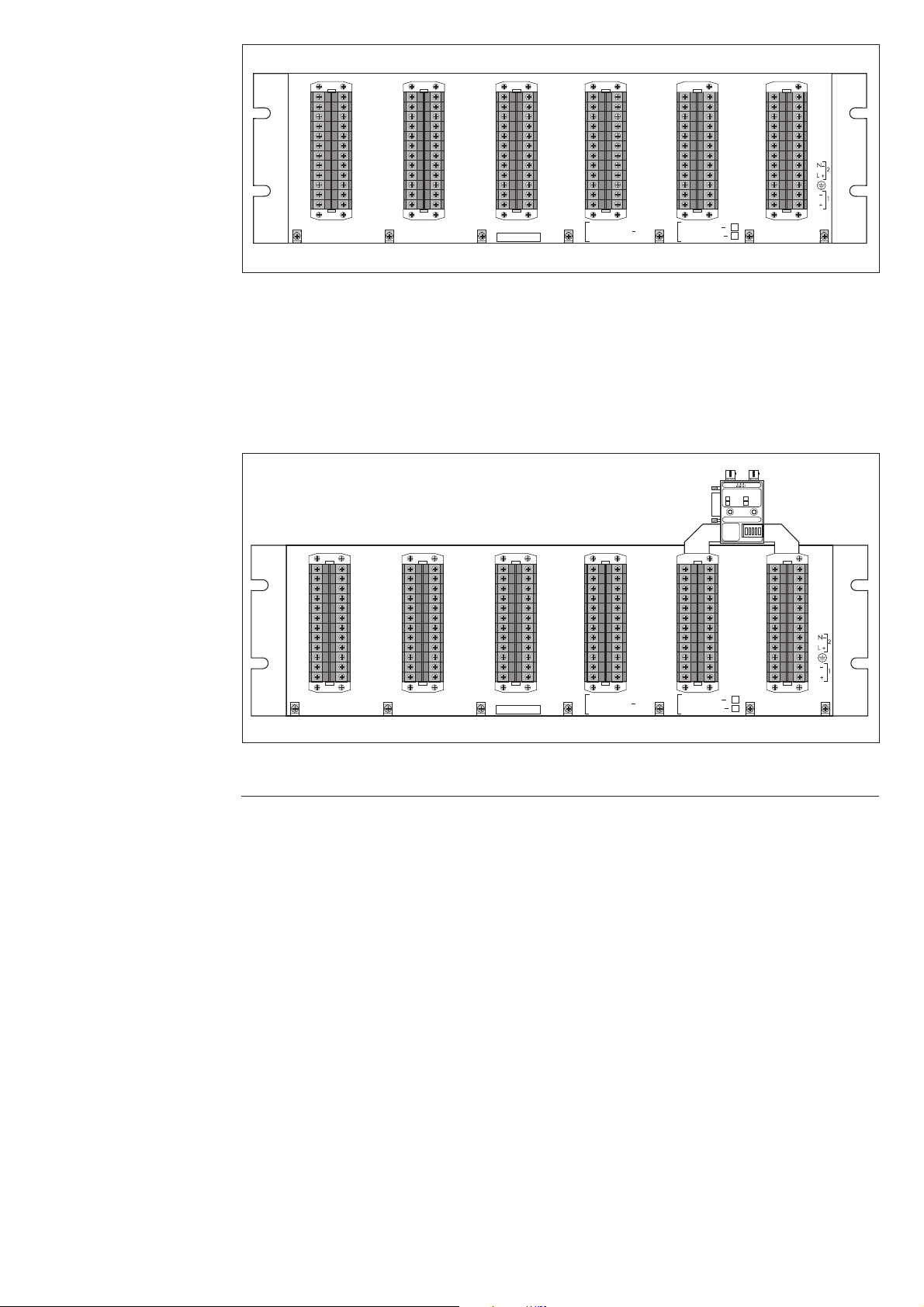

Example of system arrangement ................................................................................ 6

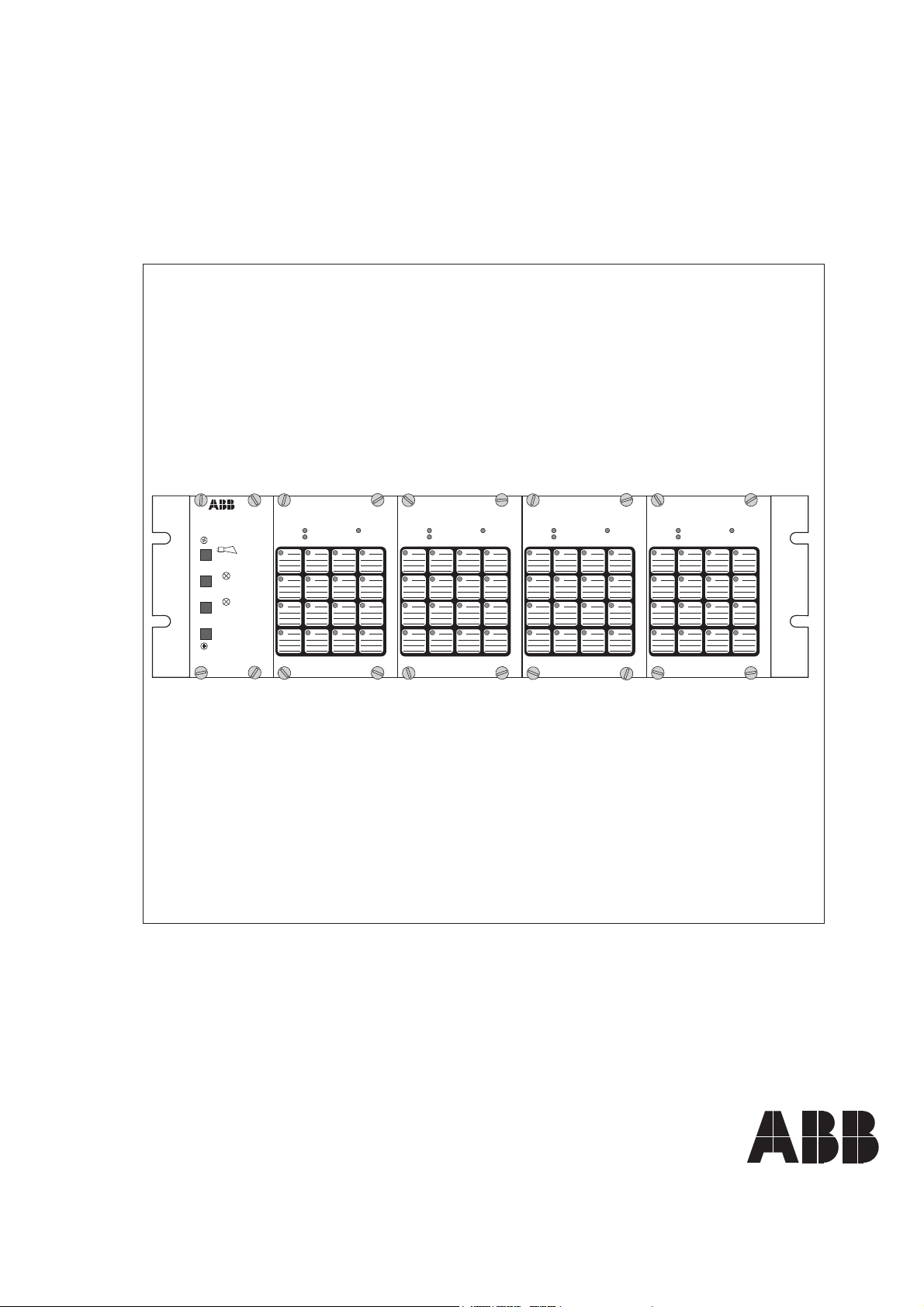

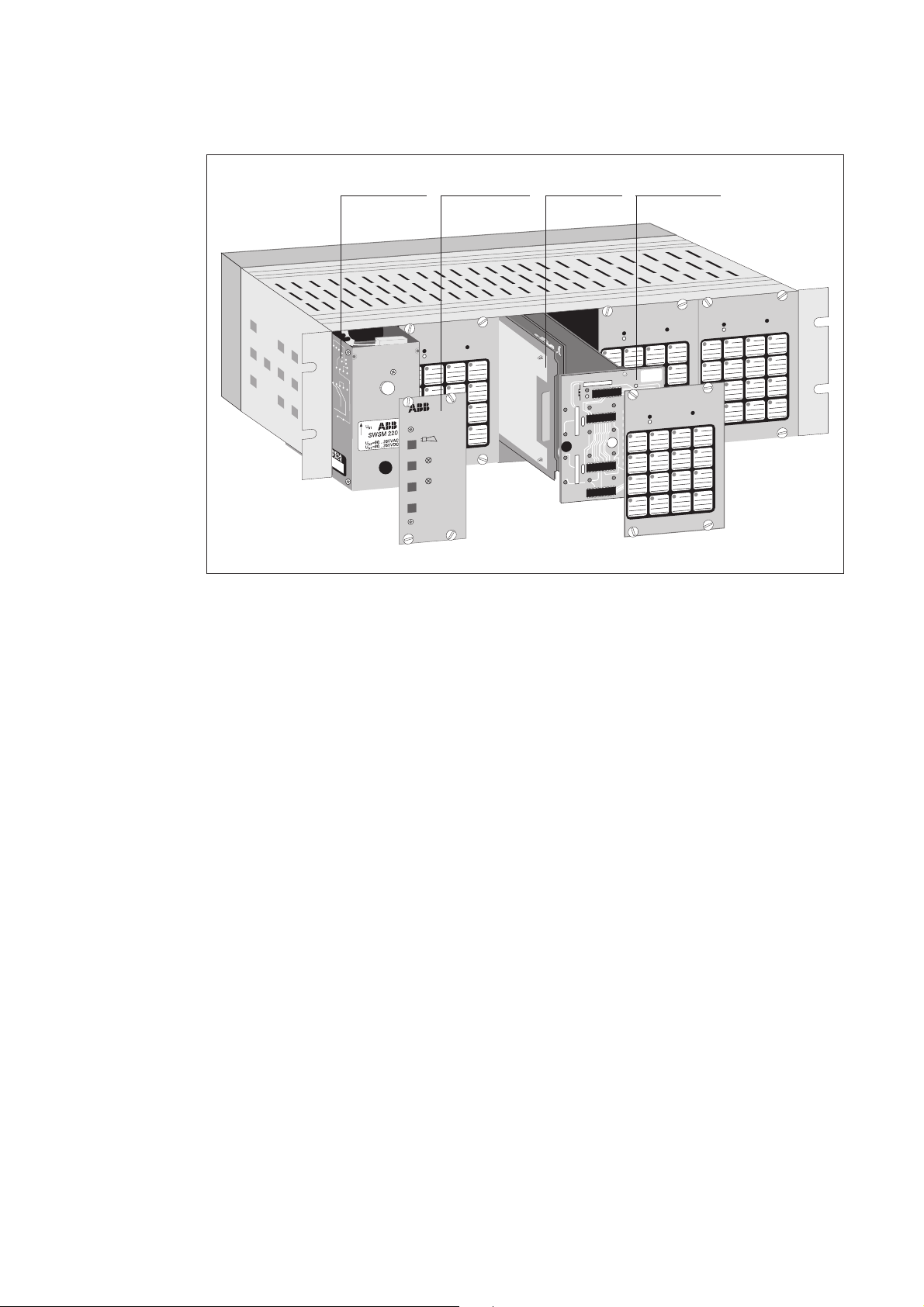

Mechanical design ..................................................................................................... 8

Function of the annunciator module .................................................................... 9

Field contact circuits .......................................................................................... 10

Alarm channel functions .................................................................................... 10

Visual alarm indication....................................................................................... 12

Standardized operational sequences .................................................................... 12

Event register for the serial communication ........................................................ 14

Auxiliary outputs ................................................................................................ 15

Group alarm reflash signals................................................................................. 15

Field contact follower output.............................................................................. 16

Lamp follower output......................................................................................... 17

Audible device output ........................................................................................ 17

Interlockings ...................................................................................................... 18

Example of channel interlocking configuration .................................................. 19

Serial communication interface ............................................................................... 20

Synchronizing of the blinking sequence ............................................................. 20

Parameterization ...................................................................................................... 21

Auxiliary power supply system ................................................................................. 21

Self-supervision output ............................................................................................ 22

Application .............................................................................................................. 23

Mounting ........................................................................................................... 23

Connection diagram ........................................................................................... 24

Terminals and wiring .......................................................................................... 25

Mounting and connection of acknowledge module SWDM 3A1 ....................... 26

Connection to a distributed system with or without event sequence reporting ... 27

Connection to a distributed system .................................................................... 27

Connection of a relay output extension unit type SACO 128R4........................ 28

Start-up .............................................................................................................. 28

Operational test .................................................................................................. 28

Legend plate ....................................................................................................... 29

Programming ................................................................................................................ 30

Signalling and reporting functions ........................................................................... 30

Parameter selection key............................................................................................ 32

Parameter chart........................................................................................................ 32

Channel interlocking scheme................................................................................... 33

Remote information to and from the alarm annunciator ......................................... 34

Event codes.............................................................................................................. 38

Technical data ............................................................................................................... 38

Testing .......................................................................................................................... 40

Maintenance and repair ................................................................................................ 40

Spareparts ..................................................................................................................... 41

Order information ........................................................................................................ 42

Troubleshooting ............................................................................................................ 42