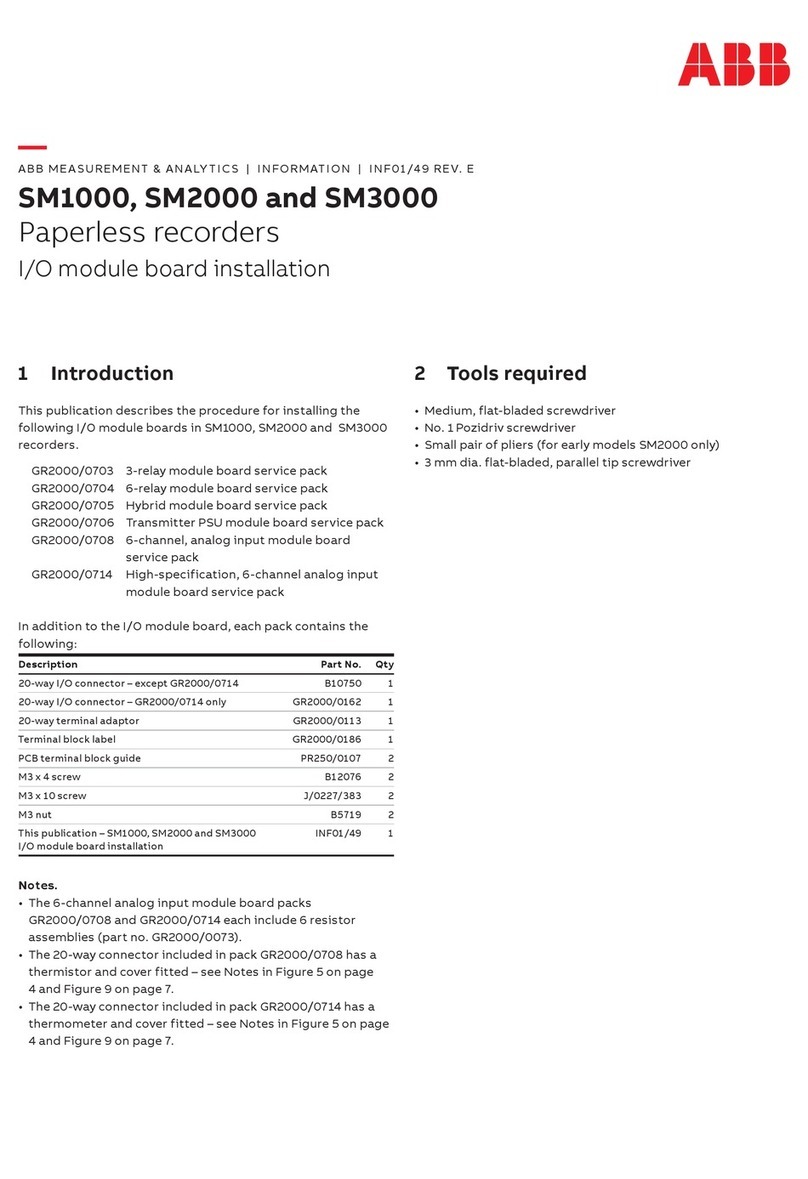

Contents

General information and instructions . . . . . . . . . . . . . . . .2

Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Agency Approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Component Material List . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Product identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Mounting the Positioner. . . . . . . . . . . . . . . . . . . . . . . . . . .7

Tubing Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Electrical Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

General information and instructions

These instructions are an important part of the product and

must be retained for future reference. Installation, commission-

ing, and maintenance of the product may only be performed by

trained specialist personnel who have been authorized by the

plant operator accordingly. The specialist personnel must have

read and understood the manual and must comply with its in-

structions.

For additional information or if specific problems occur that

are not discussed in these instructions, contact the

manufacturer. The content of these instructions is neither part

of nor an amendment to any previous or existing agreement,

promise or legal relationship.

Introduction

This document is intended for control engineers with in-depth

knowledge of positioners and positioner applications. The quick

start guide highlights the major points of installation and

calibration. Detailed installation and calibration information is

contained in the Operating Instruction (OI/AV12). It is strongly

recommend to download and use the Operating Instruction

manual for initial setup and operation.

Return of Equipment

All equipment being returned to the factory for repair must be

free of any hazardous materials (acids, alkalis, solvents, etc.). A

Material Safety Data Sheet (MSDS) for all process liquids must

accompany returned equipment. Contact the factory for

authorization prior to returning equipment.

Contacting the Factory

Should assistance be required with any of the company’s

products, contact the following:

Telephone: 1-800-HELP-365

E-Mail: automationsupport@us.abb.com

Trademarks and Registrations

Registrations and trademarks used in this document include:

Registered trademark of

® Delrin E.I. DuPont de Nemours Company, Incorporated

® Dow Corning Dow Corning Corporation

® Lexan General Electric Company, GE Plastics Division

® Monel International Nickel Company

® Noryl General Electric Company, GE Plastics Division

® PowerRac DeZurik, a Unit of General Signal

® Rynite E.I. DuPont de Nemours Company, Incorporated

® Teflon E.I. DuPont de Nemours Company, Incorporated

® Valox General Electric Company, GE Plastics Division

® Viton E.I. DuPont de Nemours Company, Incorporated

POSSIBLE PROCESS UPSETS.

Maintenance must be performed only by qualified personnel

and only after securing equipment controlled by this product.

Adjusting or removing this product while it is in the system

may upset the process being controlled. Some process up-

sets may cause injury or damage.

and is issued in strict confidence. Its use, or reproduction for

use, for the reverse engineering, development or manufacture

of hardware or software described herein is prohibited. No part

of this document may be photocopied or reproduced without

the prior written consent of ABB Inc..

2 AVI and AV2 POSITIONERS | SOI/AV12 R E V. A

Warnings

The warnings in these instructions are structured as follows:

DANGER

The signal word ‘DANGER’ indicates an imminent danger.

Failure to observe this information will result in death or

severe injury.

WARNING

The signal word ‘WARNING’ indicates an imminent danger.

Failure to observe this information may result in death or

severe injury.

CAUTION

The signal word ‘CAUTION’ indicates an imminent danger.

Failure to observe this information may result in minor or

moderate injury.

NOTICE

The signal word ‘NOTICE’ indicates potential material

damage.

Note - ‘Note’ indicates useful or important information

about the product.

Do not install, maintain or operate this equipment without

reading, understanding and following the proper factory-sup-

plied instructions and manuals, otherwise injury or damage

may result.