1

Shunt Resistors

(1 per analog input)

Mounting Clamps (x4)

Keys

CONTENTS

1INTRODUCTION .............................................................. 2

2OPERATION ..................................................................... 3

2.1 Powering Up the Instrument .............................................. 3

2.2 Displays and Controls ....................................................... 3

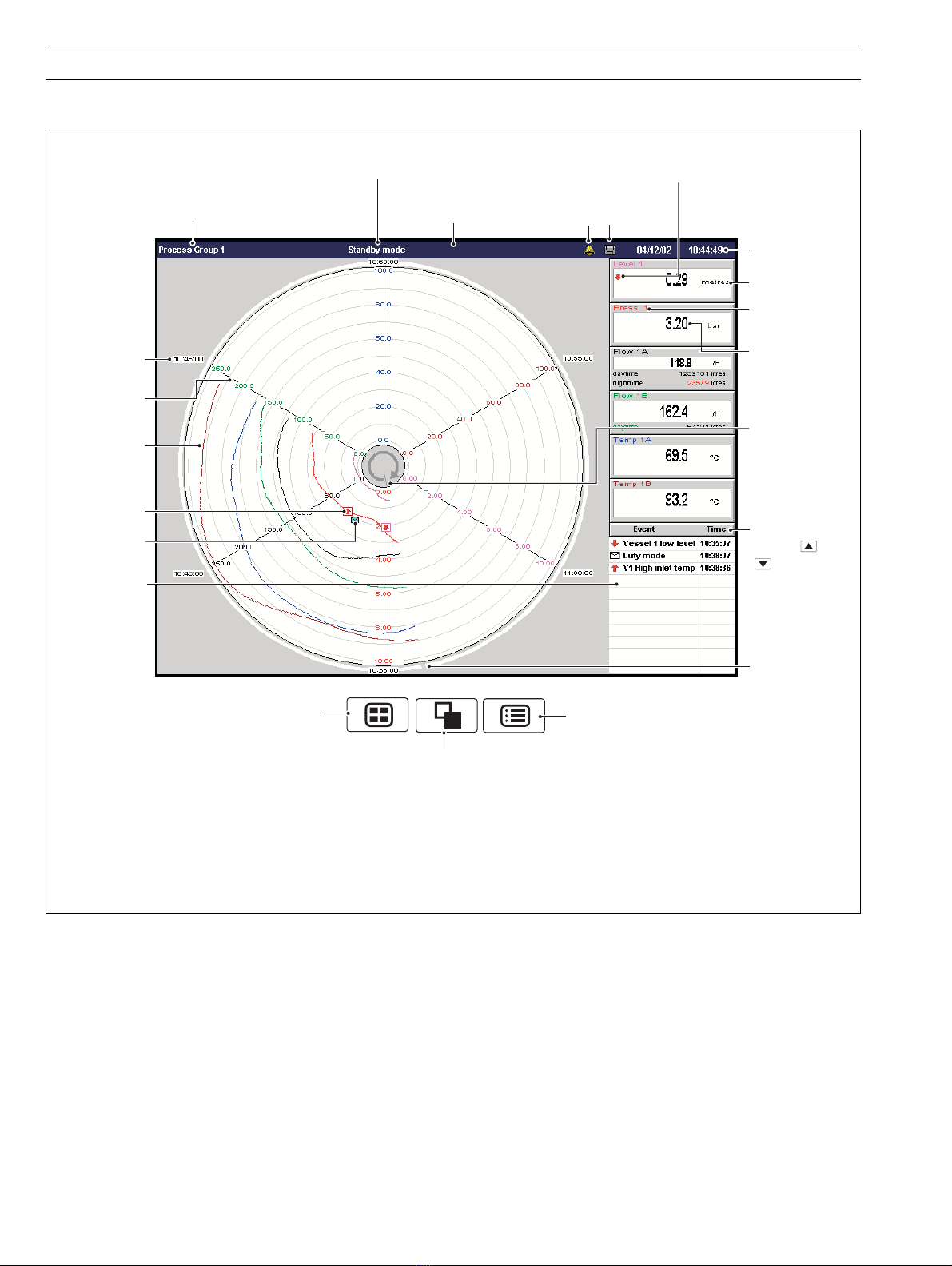

2.3 Chart Views ....................................................................... 5

2.3.1 Electronic Signatures .......................................... 13

2.4 Bargraph Views ............................................................... 14

2.5 Digital Indicator View ....................................................... 16

2.6 Process View .................................................................. 19

2.7 Instrument Status / Audit Log View ................................. 21

2.7.1 Instrument Status View ....................................... 22

2.7.2 Audit Log View ................................................... 23

2.8 Alarm Event Log .............................................................. 24

2.9 Totalizer Log .................................................................... 26

3SETUP ............................................................................ 28

3.1 Introduction ..................................................................... 28

3.2 Accessing the Setup Level .............................................. 28

3.3 Password Entry ............................................................... 29

3.4 Setup Menu .................................................................... 30

3.5 Archiving ......................................................................... 32

3.5.1 SmartMedia Handling and Care .......................... 32

3.5.2 Media Status ...................................................... 32

3.5.3 Inserting and Removing Media ........................... 33

3.5.4 Archive File Types ............................................... 34

3.5.5 Archive Filenames ............................................... 34

3.5.6 Channel Data Files .............................................. 34

3.5.7 Log files .............................................................. 35

3.5.8 On-line/Off-line ................................................... 35

3.5.9 Data Verification and Integrity.............................. 35

3.5.10 Backing Up Archived Data .................................. 35

3.5.11 File Formats ........................................................ 36

4CONFIGURATION .......................................................... 38

4.1 Introduction ..................................................................... 38

4.1.1 Configuration Level Security ............................... 38

4.1.2 Configuration Level Access ................................ 38

4.2 Overview of Configuration ............................................... 41

4.3 Making Changes to Parameters ...................................... 42

4.4 Common Configuration ................................................... 48

4.4.1 Setup ................................................................. 48

4.4.2 Security .............................................................. 51

4.4.3 Logs ................................................................... 53

4.4.4 Operator Messages ............................................ 53

4.4.5 Ethernet ............................................................. 54

4.4.6 e-mail ................................................................. 55

4.5 Process Group Configuration .......................................... 57

4.5.1 Setting the Recording Parameters ...................... 57

4.5.2 Configuring the Chart View ................................. 59

4.5.3 Configuring the Bargraph View ........................... 61

4.5.4 Configuring the Process View ............................. 62

4.5.5 Configuring the Digital Indicator View .................. 63

4.5.6 Archiving ............................................................ 65

4.6 Channel Configuration ..................................................... 66

4.6.1 Recording Channel Setup ................................... 67

4.6.2 Analog Input Configuration ................................. 69

4.6.3 Digital Input Configuration ................................... 71

4.6.4 Alarm Configuration ............................................ 72

4.6.5 Totalizer Configuration ........................................ 77

4.7 I/O Module Configuration ................................................ 80

4.7.1 Analog Inputs ..................................................... 80

4.7.2 Relay Modules .................................................... 81

4.7.3 Hybrid Modules .................................................. 82

4.7.4 RS485 (Modbus) Modules .................................. 83

4.8 Functions ........................................................................ 84

4.8.1 Custom Linearizers ............................................. 84

4.8.2 Real-time Alarms ................................................ 85

5INSTALLATION .............................................................. 86

5.1 Siting ............................................................................... 86

5.2 Mounting ......................................................................... 87

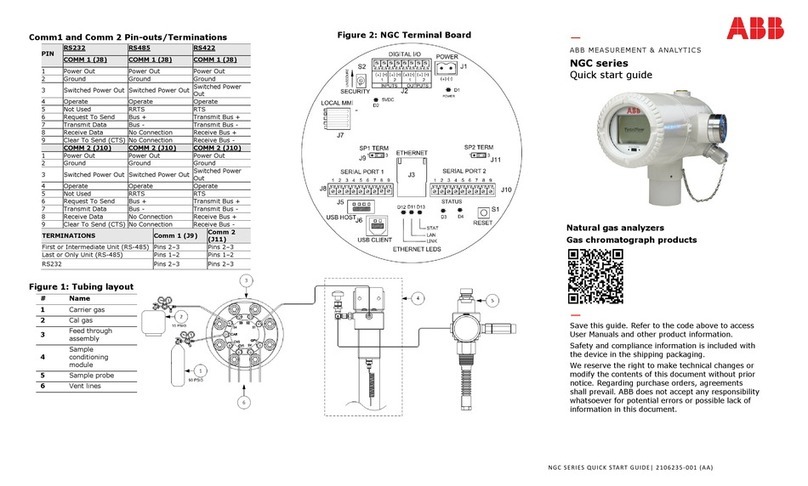

5.3 Electrical Connections ..................................................... 88

5.4 Analog Inputs .................................................................. 90

5.4.1 Current and Voltage ............................................ 90

5.4.2 Thermocouple .................................................... 90

5.4.3 Resistance Thermometer (RTD) .......................... 90

5.4.4 Transmitter Power Supply ................................... 90

5.5 Mains Power Connections ............................................... 91

5.6 Relay Output Board Connections .................................... 91

5.7 Hybrid I/O Module Connections ...................................... 92

5.7.1 Digital Output Connections ................................. 92

5.7.2 Digital Input Connections .................................... 92

5.7.3 Analog Output Connections ............................... 92

5.8 Ethernet Network Connections ........................................ 93

5.8.1 Direct Connection to a Computer ....................... 93

5.8.2 Connection to a Network Hub ............................ 94

5.8.3 Connection to a Dial-Up Router .......................... 94

5.8.4 Connection to an Internet Gateway .................... 94

APPENDIX 1 – SIGNAL SOURCES .................................... 95

APPENDIX 2 – STORAGE CAPACITY ................................ 96

A2.1 Internal Storage Capacity ................................................ 96

A2.2 Archive Storage Capacity ................................................ 97

APPENDIX 3 – DEFAULT SETTINGS ................................. 98

A3.1 Company Standard ......................................................... 98

A3.1.1 Common Configuration ...................................... 98

A3.1.2 Process Groups 1 to 6 ....................................... 98

A3.1.3 Recording Channels ........................................... 99

A3.1.4 I/O Modules ........................................................ 99

A3.1.5 Functions ......................................................... 100

A3.2 QuickStart Templates .................................................... 100

A3.2.1 QSMilliAmp ....................................................... 100

A3.2.2 QSFlow ............................................................ 100

A3.2.3 QSTHC_C ........................................................ 100

A3.2.4 QSTHC_F ......................................................... 100

A3.2.5 QSRTD_C ........................................................ 101

A3.2.6 QSRTD_F ......................................................... 101

A3.2.7 QSDEMO ......................................................... 101

APPENDIX 4 – ETHERNET ............................................... 102

A4.1 Introduction ................................................................... 102

A4.2 Testing a Network Connection ....................................... 103

A4.3 Configuring FTP Access ................................................ 103

A4.4 Using the Instrument's Web Server ............................... 107

A4.5 Glossary of Terms ......................................................... 112

APPENDIX 5 – SPARE PARTS & ACCESSORIES ........... 113

APPENDIX 6 – ERROR &

DIAGNOSTICS INFORMATION ........................................ 114

INDEX ................................................................................ 115

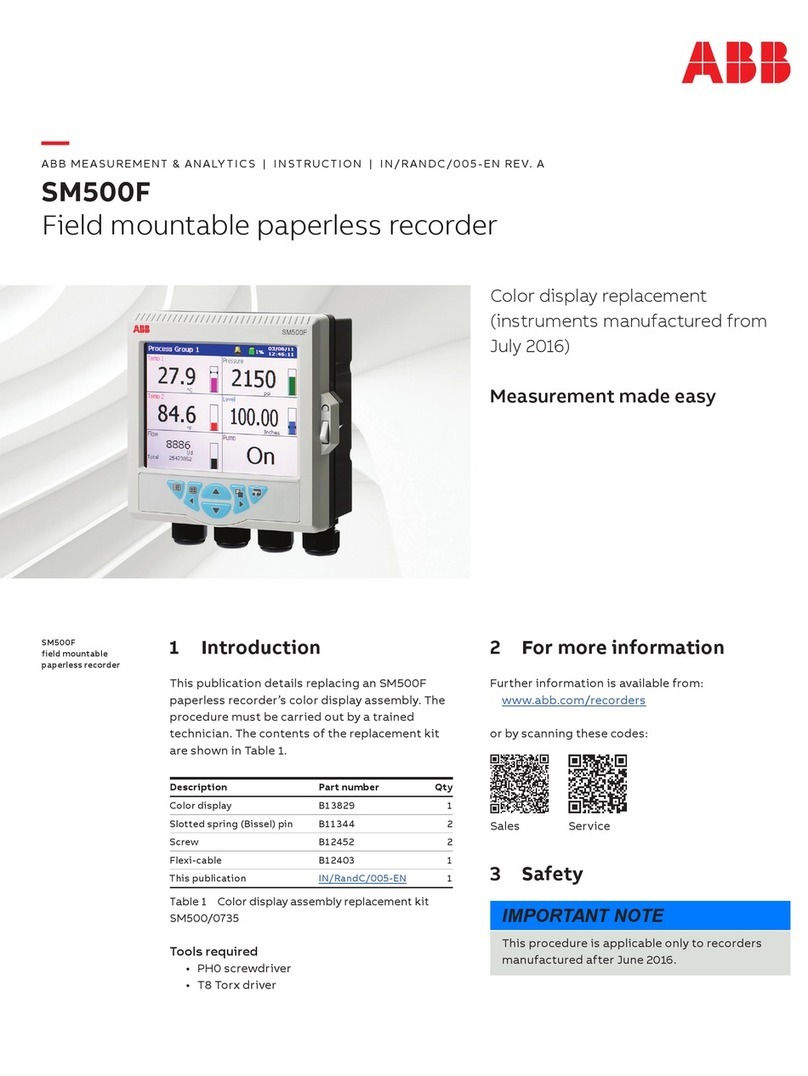

Standard Accessories

Note. For optional accessories, refer to APPENDIX 5.