1

CONTENTS 1 INTRODUCTION

1 INTRODUCTION........................................ 1

2 MECHANICAL INSTALLATION ................2

2.1 Unpacking .........................................3

2.2 Installation Conditions.......................3

2.3 Mechanical Installation......................5

2.3.1 Transmitters..........................5

2.3.2 Sensors.................................5

3 ELECTRICAL INSTALLATION ................. 5

3.1 Grounding..........................................5

3.2 Cables ...............................................6

3.2.1 Cable

(Remote Versions only) ........6

3.2.2 Cable (Alternative Type –

North American Wiring

Practice)................................7

3.2.3 Cable Glands

(IEC Installation Practice) ....7

3.2.4 Conduit Adapters

and Cable Glands

(North American – 0.5in) ......8

3.3 Connection Requirements ................8

3.3.1 Sensors................................. 8

3.3.2 Transmitters

(All versions).......................10

3.3.3 MagMaster-CalMaster

Adapter ............................... 11

3.4 Input/Output Connections ...............12

3.4.1 Frequency Outputs.............12

3.4.2 PLC Interface......................12

3.4.3 Alarm Outputs.....................13

3.4.4 Contact Input ......................13

3.4.5 Current Output....................14

3.4.6 Computer Connection ........15

3.4.7 Power Supply

Connections........................16

4 STARTUP AND OPERATION .................17

4.1 Startup .............................................17

APPENDIX A – ENVIRONMENTAL

PROTECTION ................................................19

APPENDIX B – MAGMASTER BLOCK

DIAGRAM.......................................................20

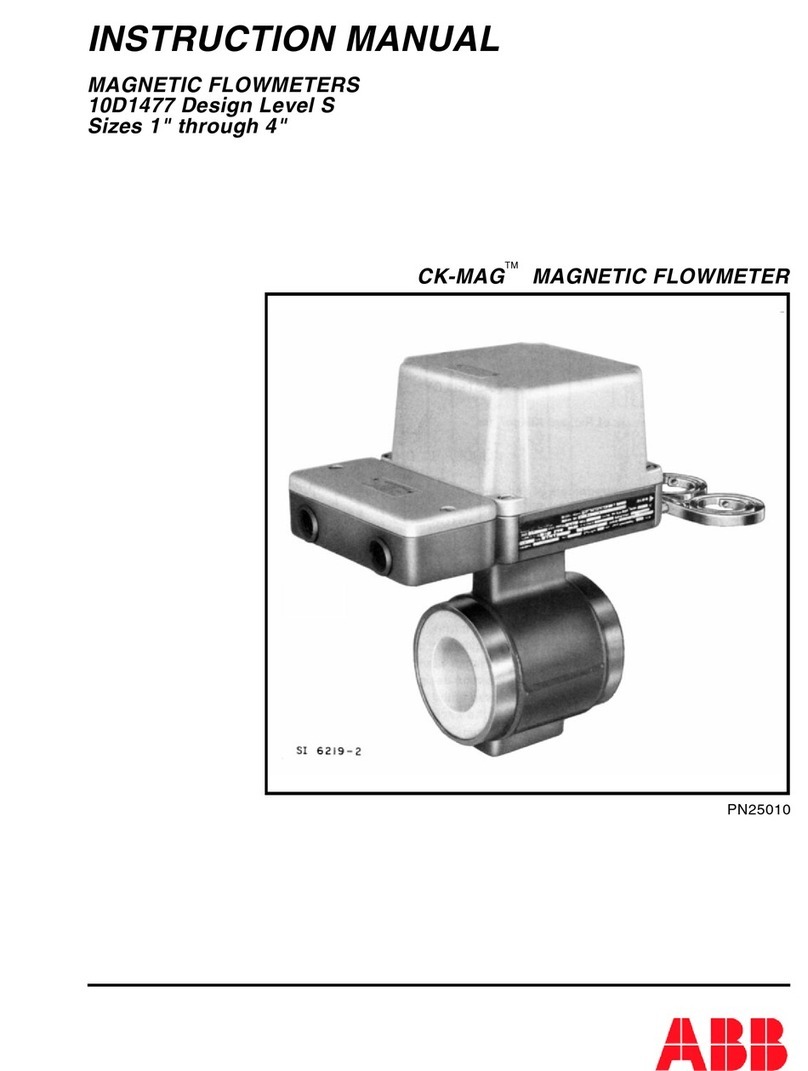

MagMasterTM is a range of high performance

electromagnetic flowmeters for the

measurement of electrically conductive fluids

and slurries, and is normally supplied as a

calibrated system, with the transmitter, factory

configured, to a supplied full-bore or insertion

probe sensor.

A wide range of options is available to suit most

applications, including:

Integral or remote transmitter.

Glass loaded polypropylene or aluminium

transmitter housing.

Combined HartTM and Keypadsupport in

the aluminium housing transmitter.

Flanged or wafer style sensors.

Insertion Probes.

Approved Versions, including:

Hazardous area operation.

Hygienic.

HARTTM communication protocol.

Warning.

For MagMaster Approved /Hazardous

Versions see the full installation manual.

Warning.

• Installation and maintenance must only

be carried out by suitably trained

personnel.

• All relevant sections of this manual must

be read before selecting a location.

• Safety requirements of this equipment,

any associated equipment and the local

environment must be taken into

consideration.

• The installation and use of this

equipment must be in accordance with

relevant national and local standards.