II F 2-5

3ADW000072R0501_DCS600_System_description_e_e

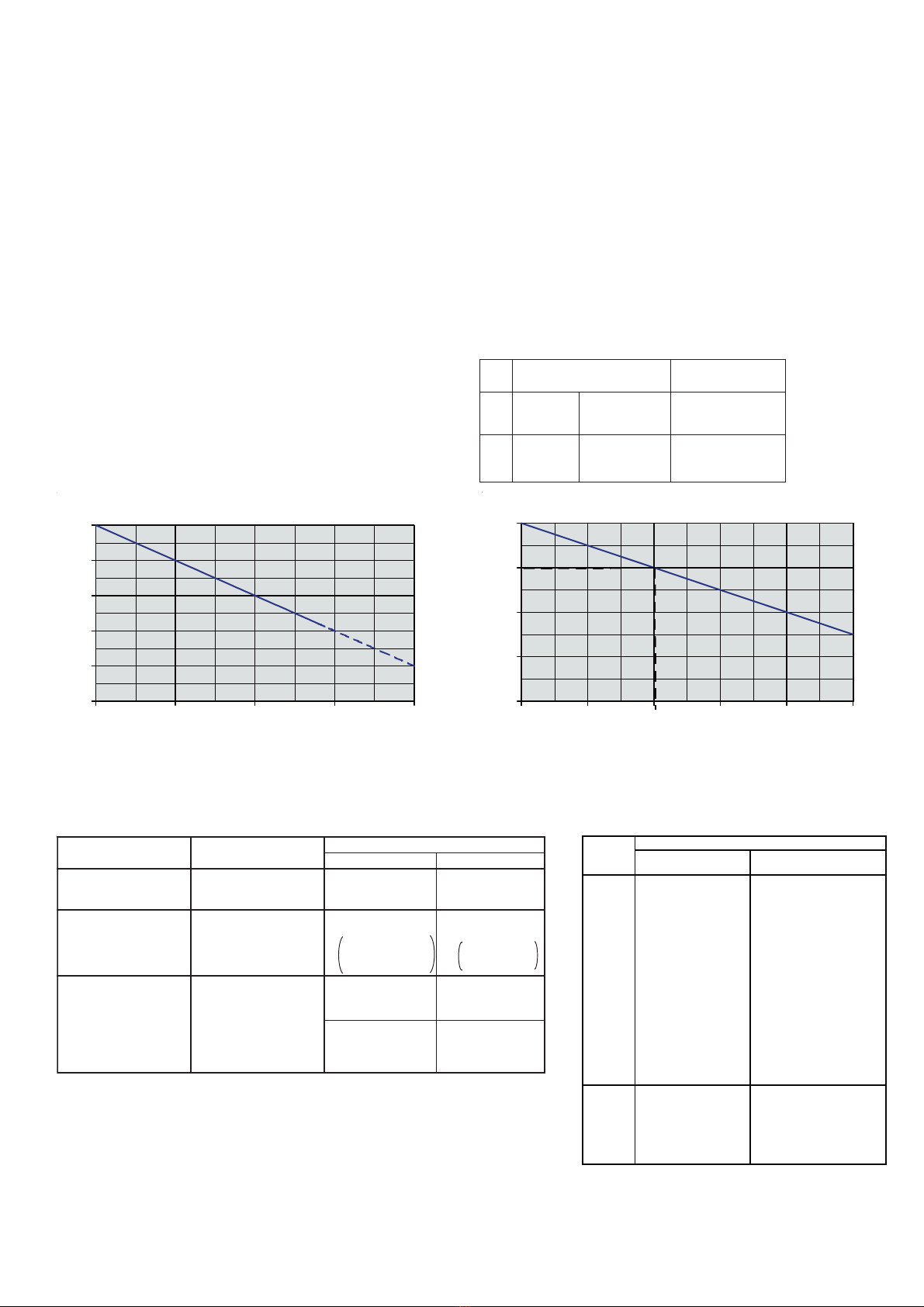

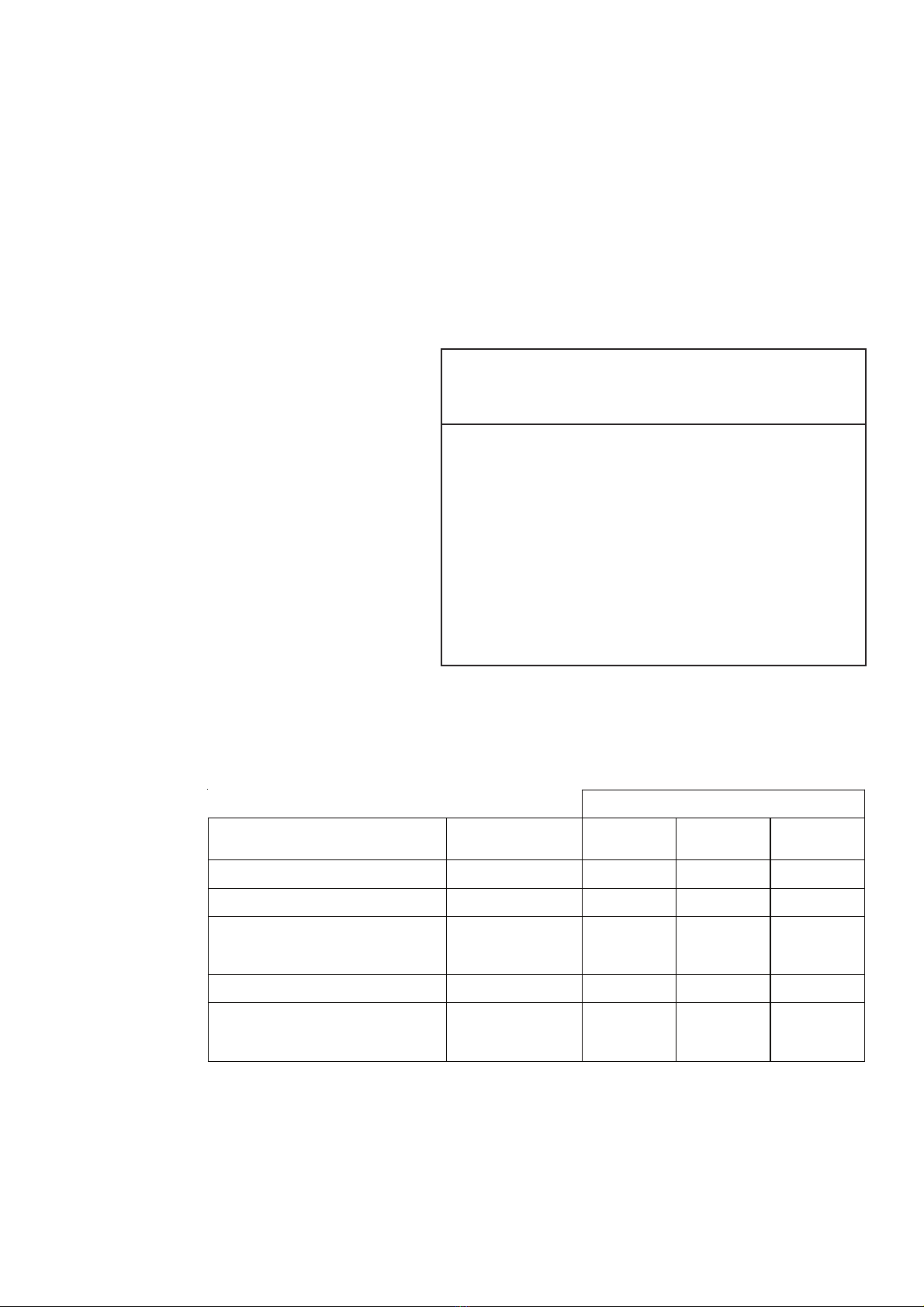

Converter type y→y=4 (400 V) y=5 (500 V) y=6 (600 V) y=7 (690 V)

x=1→2-Q IDC [A] IAC [A] P [kW] P [kW] P [kW] P [kW]

x=2 →4-Q 4Q 2Q 4Q 2Q 4Q 2Q 4Q 2Q 4Q 2Q 4Q 2Q

DCS60x-0025-y1 25 25 20 20 10 12 13 15

DCS60x-0050-y1 50 50 41 41 21 23 26 29

DCS60x-0050-61 50 50 41 41 31 35

DCS60x-0075-y1 75 75 61 61 31 35 39 44

DCS60x-0100-y1 100 100 82 82 42 47 52 58

DCS60x-0110-61 110 100 90 82 69 70

DCS60x-0140-y1 140 125 114 102 58 58 73 73

DCS60x-0200-y1 200 180 163 147 83 84 104 104

DCS60x-0250-y1 250 225 204 184 104 105 130 131

DCS60x-0270-61 270 245 220 200 169 172

DCS60x-0350-y1 350 315 286 257 145 146 182 183

DCS60x-0450-y1 450 405 367 330 187 188 234 235 281 284

DCS60x-0520-y1 520 470 424 384 216 219 270 273

DCS60x-0680-y1 680 610 555 500 282 284 354 354

DCS60x-0820-y1 820 740 670 605 340 344 426 429

DCS60x-1000-y1 1000 900 820 738 415 418 520 522

DCS60x-0903-y1 900 900 734 734 563 630 648 720

DCS60x-1203-y1 1200 1200 979 979 498 558 624 696

DCS60x-1503-y1 1500 1500 1224 1224 623 698 780 870 938 1050 1080 1200

DCS60x-2003-y1 2000 2000 1632 1632 830 930 1040 1160 1400 1600

DCF60x-0025-y1 25 25 20 20 10 12 13 15

DCF60x-0050-y1 50 50 41 41 21 23 26 29

DCF60x-0075-y1 75 75 61 61 31 35 39 44

DCF60x-0100-y1 100 100 82 82 42 47 52 58

DCF60x-0200-y1 200 180 163 147 83 84 104 104

DCF60x-0350-y1 350 315 286 257 145 146 182 183

DCF60x-0450-y1 450 405 367 330 187 188 234 235

DCF60x-0520-y1 520 470 424 384 216 219 270 273

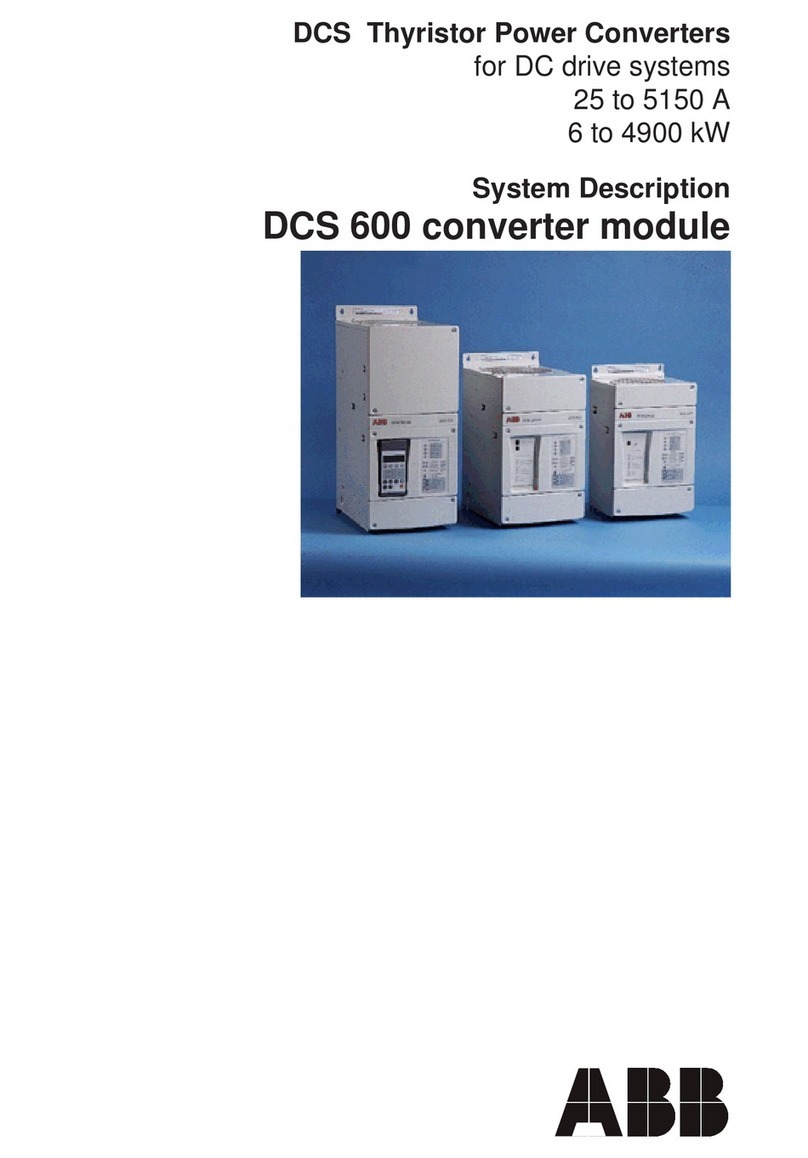

Table 2.2/3: Table of DCS 600 / DCF 600 units - construction types C1, C2, A5

Converter type y→y=4 (400 V) y=5 (500 V) y=6 (600 V) y=7 (690 V) y=8 (790 V) y=9 (1000V) y=1 (1190V)

IDC [A] IAC [A] P [kW] P [kW] P [kW] P [kW] P [kW] P [kW] P [kW] ➀

2-Q converters

DCS601-1903-y1 1900 1550 1740

DCS601-2053-y1 2050 1673 1190 1430 1640

DCS601-2503-y1 2500 2040 1160 1450 1750 2000 2300

DCS601-3003-y1 3000 2448 1395 1740 2090 2400 2750

DCS601-2053-y1 2050 1673 2390

DCS601-2603-y1 2600 2121 3030

on request

DCS601-3303-y1 3300 2693 1540 1925 2310 2660 3040 3850

on request

DCS601-4003-y1 4000 3264 1870 2330 2800 3220 3690 4670

on request

DCS601-4803-y1 4800 3917 3360 3860 4420

DCS601-5203-y1 5200 4243 2430 3030

4-Q converters

DCS602-1903-y1 1900 1550 1560

DCS602-2053-y1 2050 1673 1070 1280 1470

DCS602-2503-y1 2500 2040 1040 1300 1560 1800 2060

DCS602-3003-y1 3000 2448 1250 1560 1880 2150 2470

DCS602-2053-y1 2050 1673 2390

DCS602-2603-y1 2600 2121 3030

on request

DCS602-3303-y1 3300 2693 1375 1720 2060 2370 2720 3440

on request

DCS602-4003-y1 4000 3264 1670 2080 2500 2875 3290 4170

on request

DCS602-4803-y1 4800 3917 3000 3450 3950

DCS602-5203-y1 5200 4243 2170 2710

➀These converters are equipped with additional components. More information on request

Table 2.2/4: Table of DCS 600 units - construction type A6 / A7 Higher currents up to 15,000 A are achieved by

paralleling converters - information on request.