6

vides a latching function after any trip opera-

tion. After having latched the output relay must

be manually reset or reset by remote control.

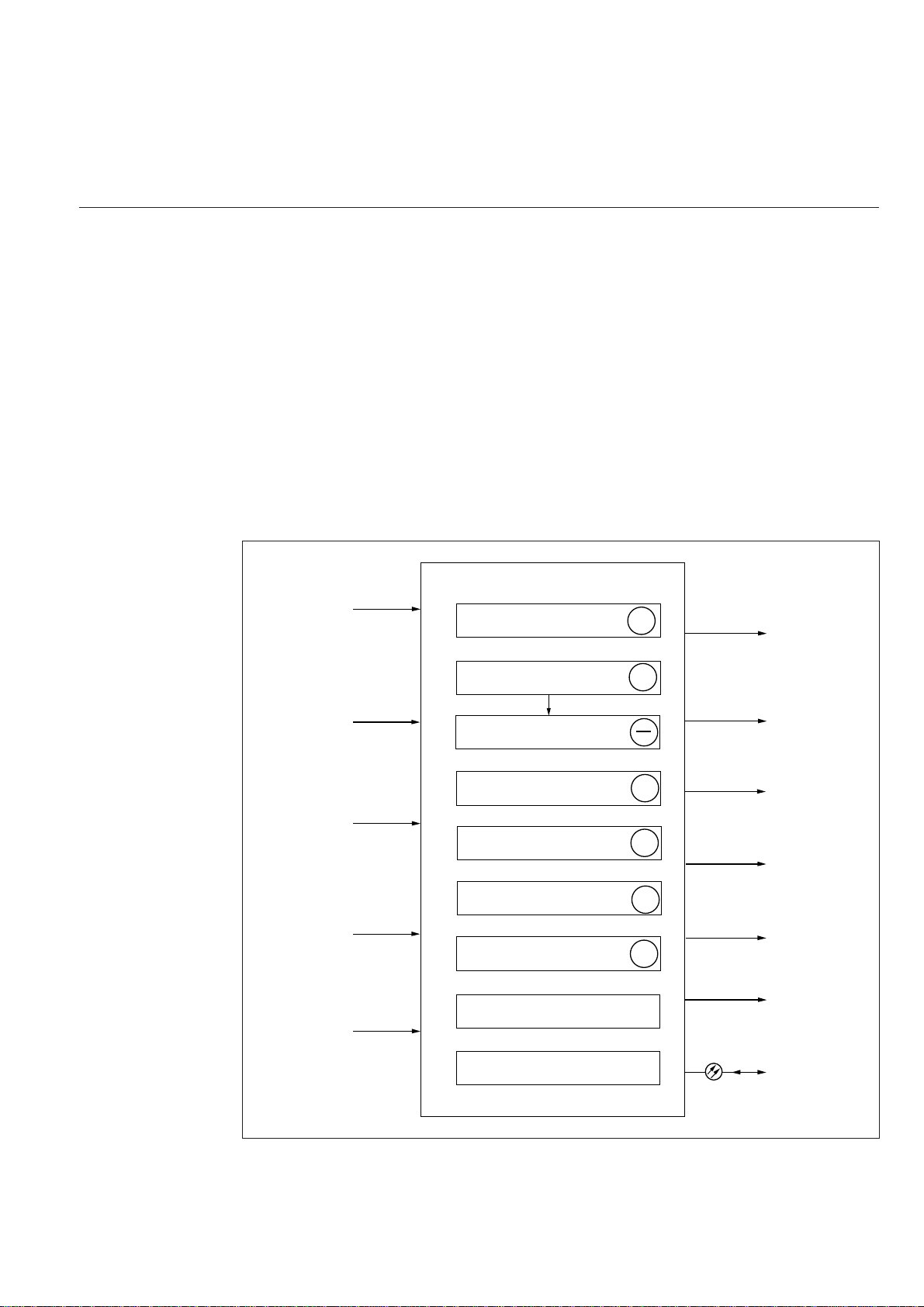

The trip alarm signals from the relay module are

obtained via output relays B and C. The signals

to be routed to these relays are selected with

switches1...7 of switchgroup SGR1 and switches

4...8 of switchgroup SGR2 of the relay module.

Normally the output relays B and C are given

such a configuration that a thermal prior alarm

is obtained over relay C and the trip signals of

the protection units are linked to output relay B

to form an auxiliary trip signal. This is also the

default setting of the relay on delivery from the

factory.

The signals to be routed to the output relay D

are selected with switches 1, 2 and 3 of software

switchgroup SGR2 in the main menu of the

relay module. Switch SGR2/1 routes the ther-

mal prior alarm, switch SGR2/2 routes the

startup information for the motor and switch

SGR2/3 routes the start signal of the high-set

overcurrent stage to output relay D.

Output relay E, terminals 74-75, is a heavy duty

output relay capable of controlling a circuit

breaker, as the main trip relay A. Relay E is used

for controlling the restart of the motor. If the

thermal capacity used exceeds the set restart

inhibit level of the thermal unit, if the allowed

maximum cumulative start-up count is exceeded

or if the external restart inhibit signal is active

the output relay E prevents a motor restart

attempt. This also applies to a condition where

the protective relay is out of auxiliary voltage or

the relay is faulty.

Output relay F, terminals 70-71-72, operates as

the output relay of the integrated self-supervi-

sion system. The relay operates on the closed-

circuit principle, thus under normal service con-

ditions the contact gap 70-72 is closed. If a fault

is detected by the self-supervision system, or if

the auxiliary supply fails, the output relay drops

off, providing an alarm signal by closing the NO

contact 71-72.

The relay is connected to the SPA data bus by

means of bus connection module type SPA-ZC

17 or SPA-ZC21. The bus connection module

is connected to the D type connector marked

SERIAL PORT on the rear panel of the relay.

The fibre-optic cables are connected to the

connectors Tx and Rx of the bus connection

module. The communication mode selector

switches on the bus connection module are set

in position "SPA".

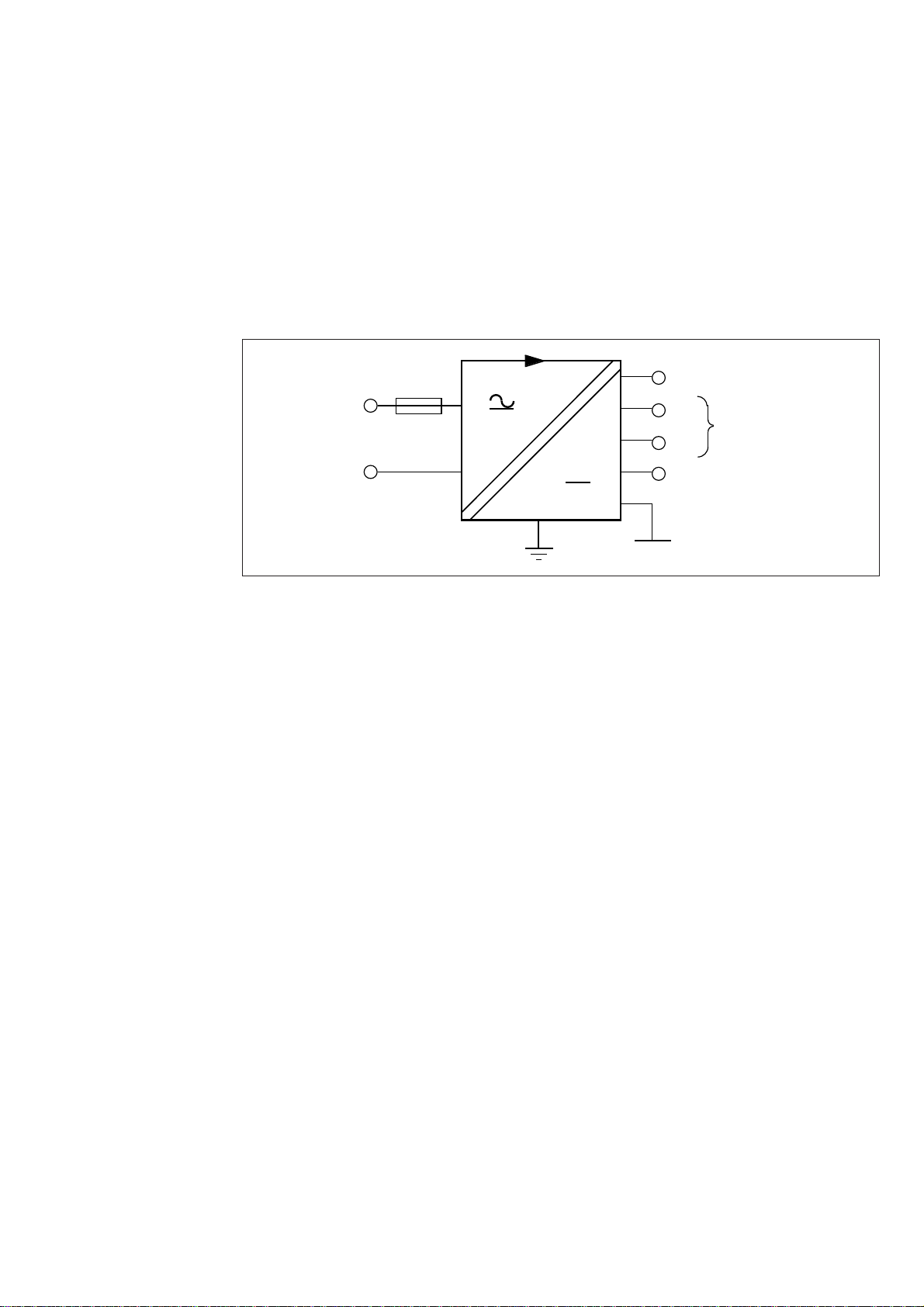

The three phase currents are connected to ter-

minals 1-2, 4-5 and 7-8, when the rated current

of the secondary circuits is In= 5 A. When using

current transformers with a rated current of 1 A,

terminals 1-3, 4-6 and 7-9 are used. The ther-

mal overload protection may also be used in

single-phase or two-phase applications, in this

case inputs not used may be left unconnected.

To get a proper operation of the unbalance and

incorrect phase sequence protection in a two-

phase application, the two phase currents should

be summed in the third phase current input. In

single-phase applications, wiring the phase cur-

rent through two or three current inputs in series

may slightly increase the operating speed of the

relay and stabilize operation of the thermal unit.

The neutral current of the earth-fault protection

is connected to terminals 25-26 when the rated

current is 5 A and to terminals 25-27 when the

rated current is 1 A.

The control input 10-11 can be used in five

different ways:

- as the control input controlled by a motor

speed switch in Ex-type applications

- as the control input of an external blocking

signal for blocking the operation of the unbal-

ance or earth-fault protection units

- as the control input for an external trip signal

- as the control input for unlatching the trip relay

- as the control input for the restart enable relay.

The designed function is selected by means of

switches 1...8 of switchgroup SGB in the main

menu of the protection relay module.

The auxiliary supply voltage of the relay is

connected to the terminals 61-62. At d.c. auxil-

iary supply voltage the positive lead is connected

to terminal 61. The accepted input voltage

range is determined by the type of power supply

and output relay module inserted in the relay

case. For further details see the description of the

power supply module. The accepted auxiliary

voltage range of the relay is indicated on the

front panel.

Output relay A provides the CB tripping com-

mands when the operate time of a protective

unit has elapsed. The earth-fault unit can be

made non-tripping, i.e. only signalling, with

switch 8 of switchgroup SGR1. On delivery from

factory all protective units are selected to per-

form tripping. A latching function of the output

relay A can be selected by means of switches

SGB/7 and SGB/8. Switch SGB/7 gives a latch-

ing function after a short-circuit, an earth-fault

or an unbalance tripping. Switch SGB/8 pro-

Connections