- 2 -TOCe

Rights reserved to alter specifications without notice.

READ THIS FIRST 3.................................................................

HOW TO USE THIS MANUAL 3.......................................................

DOCUMENTATION OVERVIEW 3.....................................................

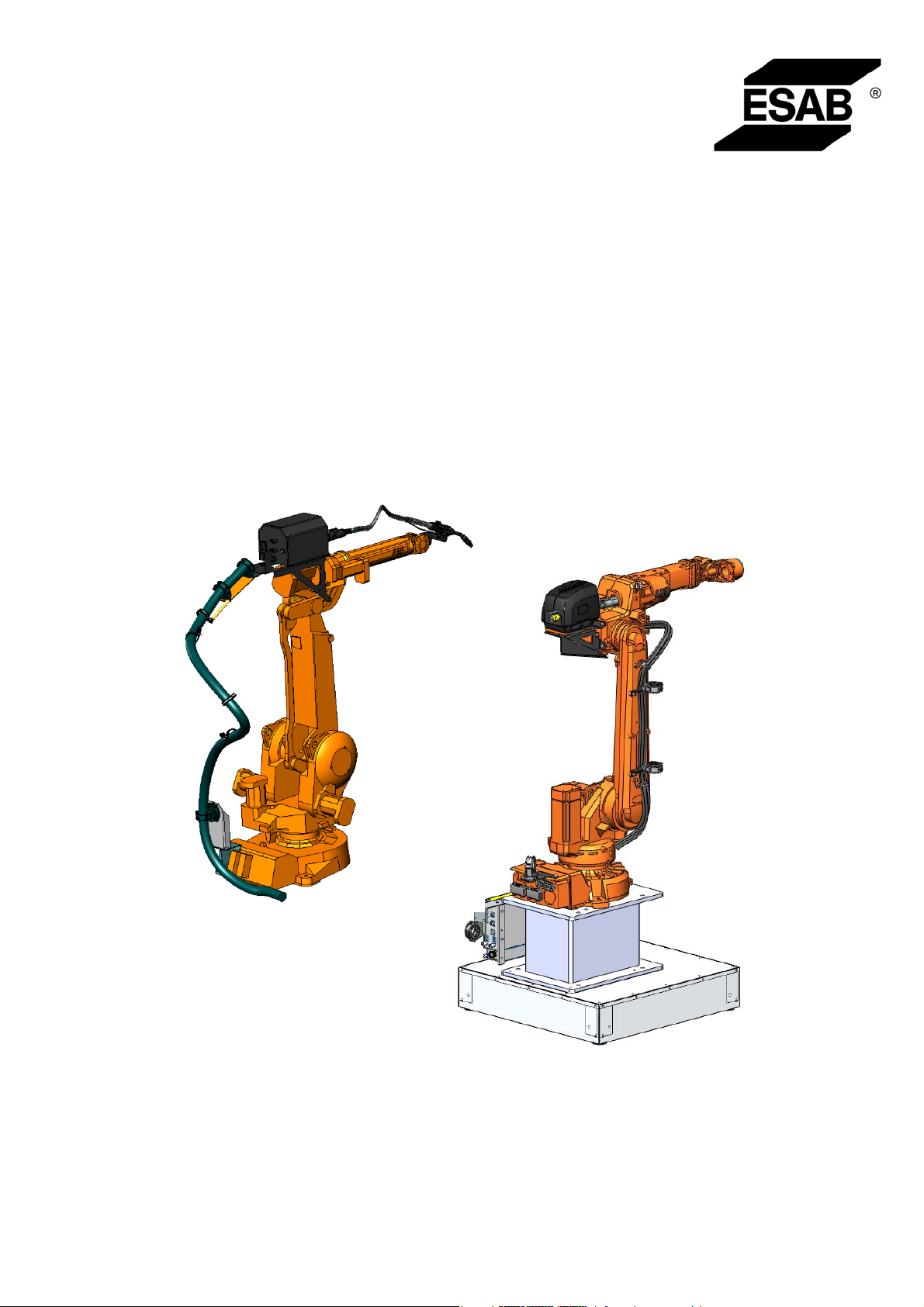

INTRODUCTION 4...................................................................

Supported equipment 4...........................................................

Schematic system design 5........................................................

W82 INTEGRATED VERSION 6.......................................................

DeviceNet (Integrated version) 6...................................................

Network connection 6.............................................................

DeviceNet network (Integrated version) 7...........................................

Termination 7.....................................................................

Location of SW1 and SW2 on the welding data board, 24AP1 8.......................

W82 ANYBUS 9.....................................................................

Fieldbus connection 9............................................................

W82 DeviceNet 10..................................................................

DeviceNet network 10..............................................................

Tap for DeviceNet at Weld Data Unit 11..............................................

Termination 11.....................................................................

Position of SW1 on the welding data board, 24AP1. 12...............................

24AP4 Fieldbus board - DeviceNet 13................................................

Fieldbus connector 13..............................................................

Configuration 14...................................................................

Baud rate 14.......................................................................

Node address (Mac ID) 14...........................................................

LED indicators 15..................................................................

INSTALLATION OF HARDWARE 16....................................................

Regarding U82 16..................................................................

Installing W82 16...................................................................

CONFIGURATION EXAMPLE 20.......................................................

IO configuration 20................................................................

Signals out 21.....................................................................

Signals in 22.......................................................................

Process definitions 24..............................................................

Cross reference Integrated 29.......................................................

Cross reference Anybus 31.........................................................

SERVICE INSTRUCTIONS 33..........................................................

What is ESD? 33...................................................................

SPARE PARTS 33....................................................................

Ordering spare parts 33............................................................