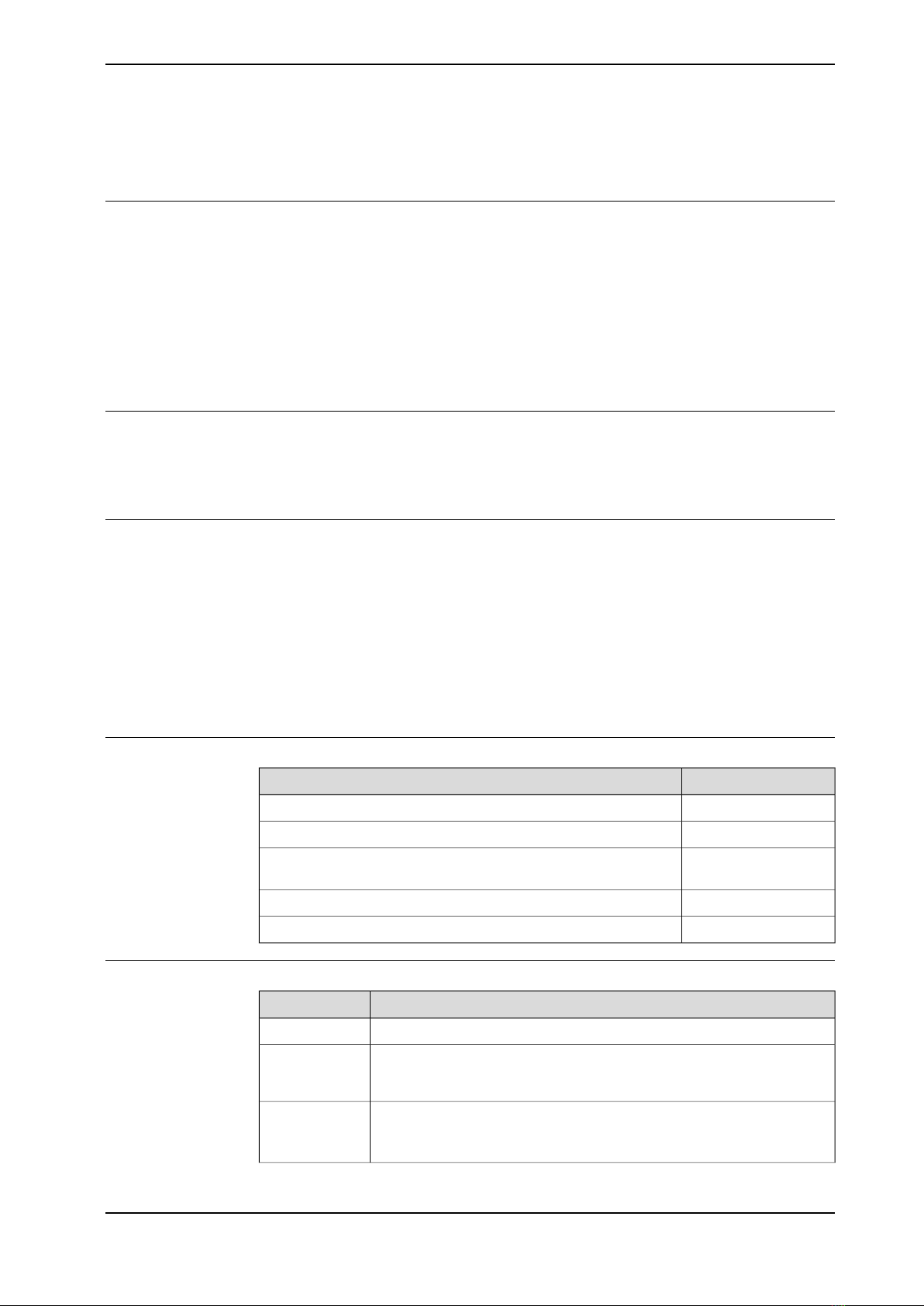

Table of contents

7Overview of this product specification .............................................................................................

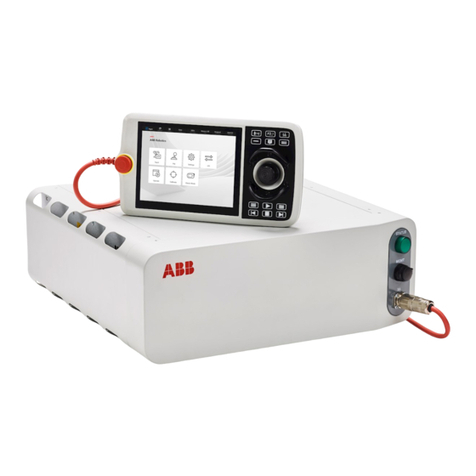

91 Description

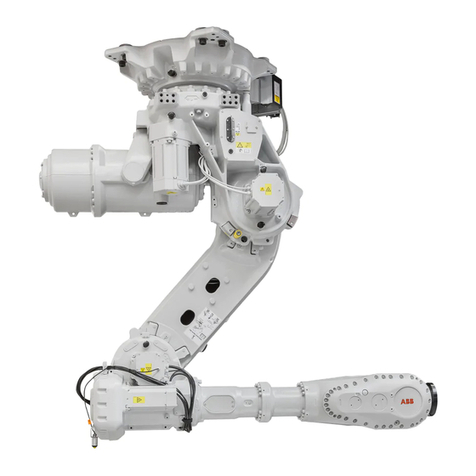

91.1 Structure .........................................................................................................

91.1.1 Introduction ............................................................................................

121.1.2 Different robot versions ............................................................................

131.1.3 Definition of version designations ...............................................................

151.2 Standards ........................................................................................................

151.2.1 Applicable standards ...............................................................................

171.3 Installation .......................................................................................................

171.3.1 Introduction to installation .........................................................................

181.3.2 Operation requirements ............................................................................

191.3.3 Assembling the manipulator ......................................................................

251.4 Calibration and references ..................................................................................

251.4.1 Calibration methods .................................................................................

271.4.2 Fine calibration .......................................................................................

281.4.3 Absolute Accuracy calibration ...................................................................

301.5 Load diagrams ..................................................................................................

301.5.1 Introduction ............................................................................................

311.5.2 Load diagrams ........................................................................................

37

1.5.3 Maximum load and moment of inertia for full and limited axis 5 (center line down)

movement ..............................................................................................

391.5.4 Wrist torque ...........................................................................................

401.5.5 Maximum TCP acceleration .......................................................................

411.6 Fitting equipment ..............................................................................................

471.7 Maintenance and troubleshooting .........................................................................

481.8 Robot motion ....................................................................................................

481.8.1 Robot motion ..........................................................................................

511.8.2 Performance according to ISO 9283 ............................................................

521.8.3 Velocity .................................................................................................

531.8.4 Robot stopping distances and times ...........................................................

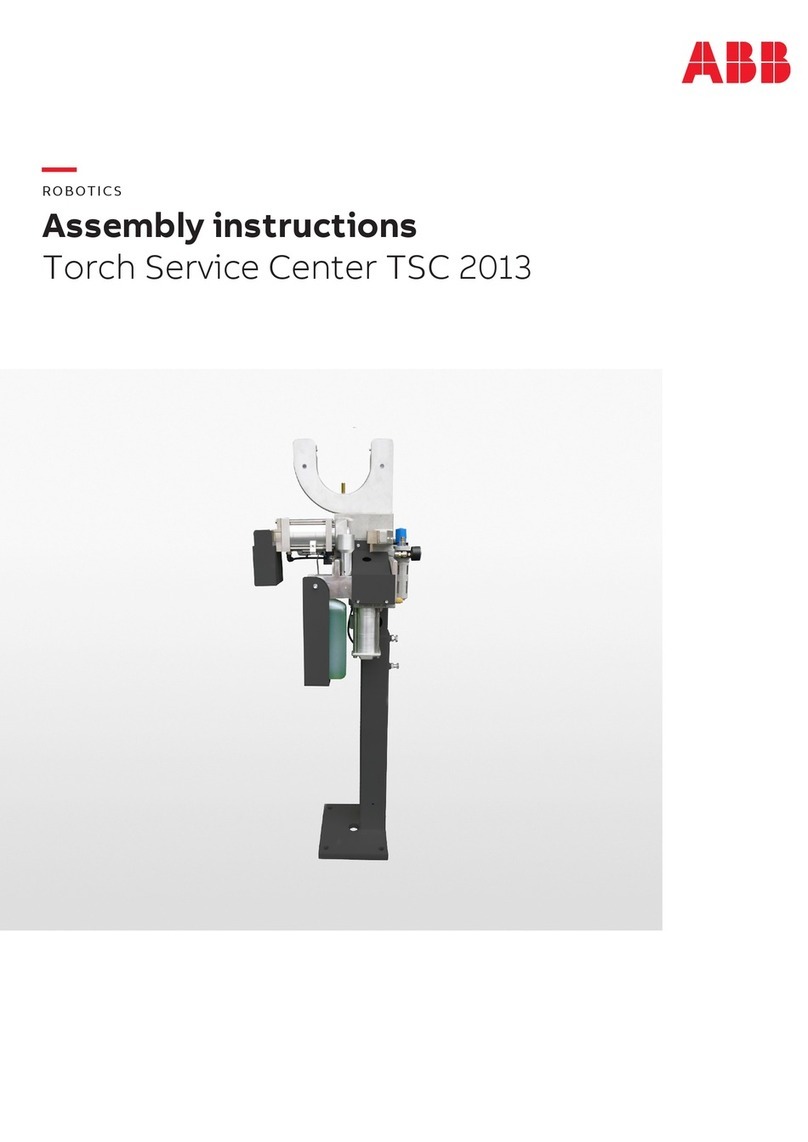

541.9 Servo gun ........................................................................................................

541.9.1 Introduction ............................................................................................

551.9.2 Stationary Gun ........................................................................................

561.9.3 Robot Gun .............................................................................................

572 DressPack

572.1 Introduction ......................................................................................................

572.1.1 Included options .....................................................................................

592.1.2 Product range .........................................................................................

602.1.3 Limitations of robot movements .................................................................

612.1.4 Impact on DressPack lifetime ....................................................................

622.1.5 Information structure ...............................................................................

632.2 DressPack .......................................................................................................

632.2.1 Introduction ............................................................................................

642.2.2 Built-in features for upper arm DressPack ....................................................

652.2.3 Interface descriptions for DressPack ...........................................................

702.2.4 Dimensions ............................................................................................

712.3 Type H/HS/HSe .................................................................................................

712.3.1 Introduction ............................................................................................

732.3.2 Configuration result for Type H HS HSe .......................................................

762.3.3 Interface description for stationary gun .......................................................

772.3.4 Summary common options Type H HS HSe .................................................

782.3.5 Summary options required for Type Hs HSe .................................................

792.4 Type Se ...........................................................................................................

792.4.1 Introduction ............................................................................................

Product specification - IRB 8700 5

3HAC052852-001 Revision: K

© Copyright 2021 ABB. All rights reserved.

Table of contents