Absco Industries Assembly Instruction Manual

ABSCO COMPACT GARAGE

MODEL: CG34552N2

3.4m W x 5.5m D x 2.17m H

Model: CG34552N2 29/09/19 3

Steps To Construct Your Garage

Identification of parts ........................................................................... 4

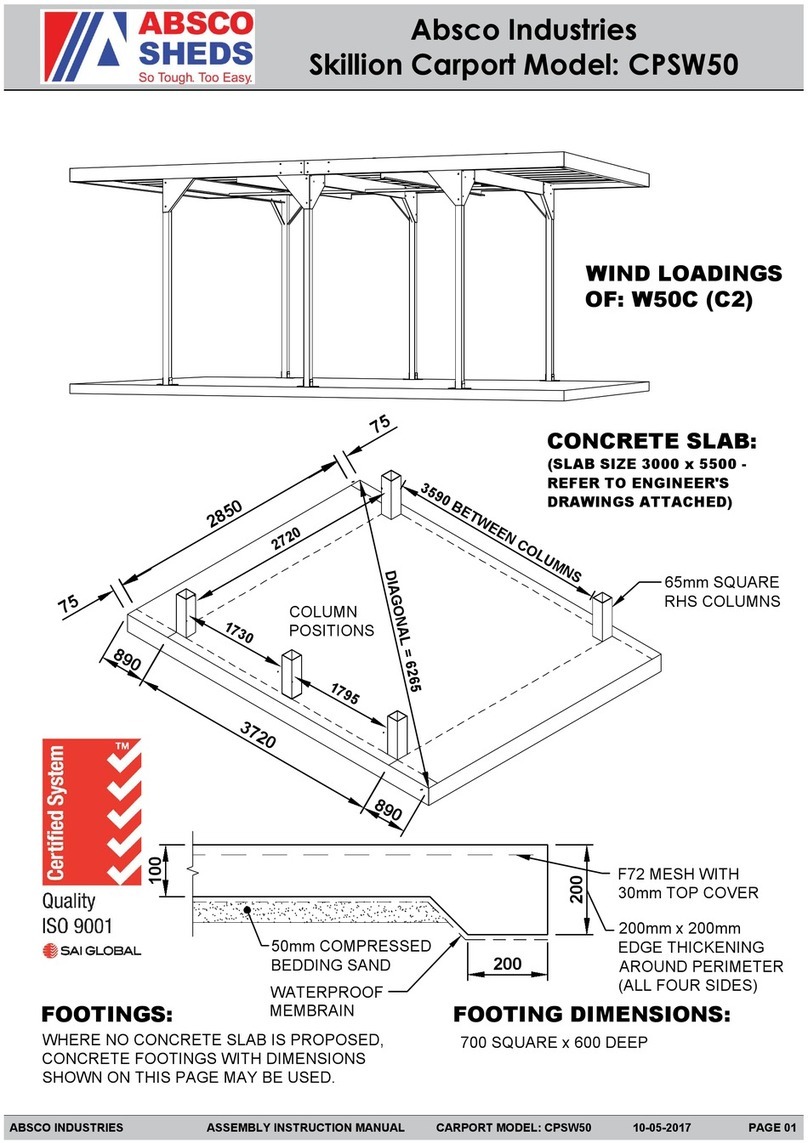

Concrete slab/ footing details ............................................................ 9

Rear frame assembly ........................................................................... 11

Center frame assembly ....................................................................... 13

Front frame assembly .......................................................................... 15

Frame layout ........................................................................................ 17

Frame construction ............................................................................. 15

Fit roof purlins ..................................................................................... 20

Fit sheeting .......................................................................................... 21

Assemble & fit barn doors ................................................................. 24

Fit gutters & trim ................................................................................. 28

Engineering drawings ......................................................................... 30

1. Part numbers

As noted on page one, part numbers have been printed on most 80 x 40 channel sections and

sheeting. All other components have not been marked with part numbers, but can be identified by

their description, size and sketches provided on pages three, four and five of this instruction.

2. Personal Access Door (P.A. Door)

If you have selected the optional Personal Access Door, P.A. Door, There is an additional

instruction manual that is to be used in conjunction with this document.

3. All components pre-cut to size

Do not cut any components to a different size, unless it is clearly noted in this instruction to do

so. Dimensions in this assembly instruction are exact, where as dimensions noted on the engineering

plans are approximate. Double check that you have the correct component for the correct location.

4. Self drilling screws

Helpful Hints

10 x 16 Hex head tek screw for general use.

Phillips head tek screw - use on outside of

front framework to maintain a smooth sur-

face to surface to secure sheeting to.

The structure is assembled using these self drilling tek screws. All roof and wall sheets are pan

fixed. ie screw through the flat pan of the sheet into the framework.

Screw driver bits are included for use in your drill. Refer to the attached engineering drawings

for the quantity of screws required per connection.

10 x 16 Hex head tek screw with neoprene

washer for securing roof sheets to

framework.