Absco Industries Assembly Instruction Manual

ABSCO GABLE CARPORT

MODEL: GCPDN2

6.0mW x 6.0mD x 2.98mH

Model: GCPDN2 8/06/23 2

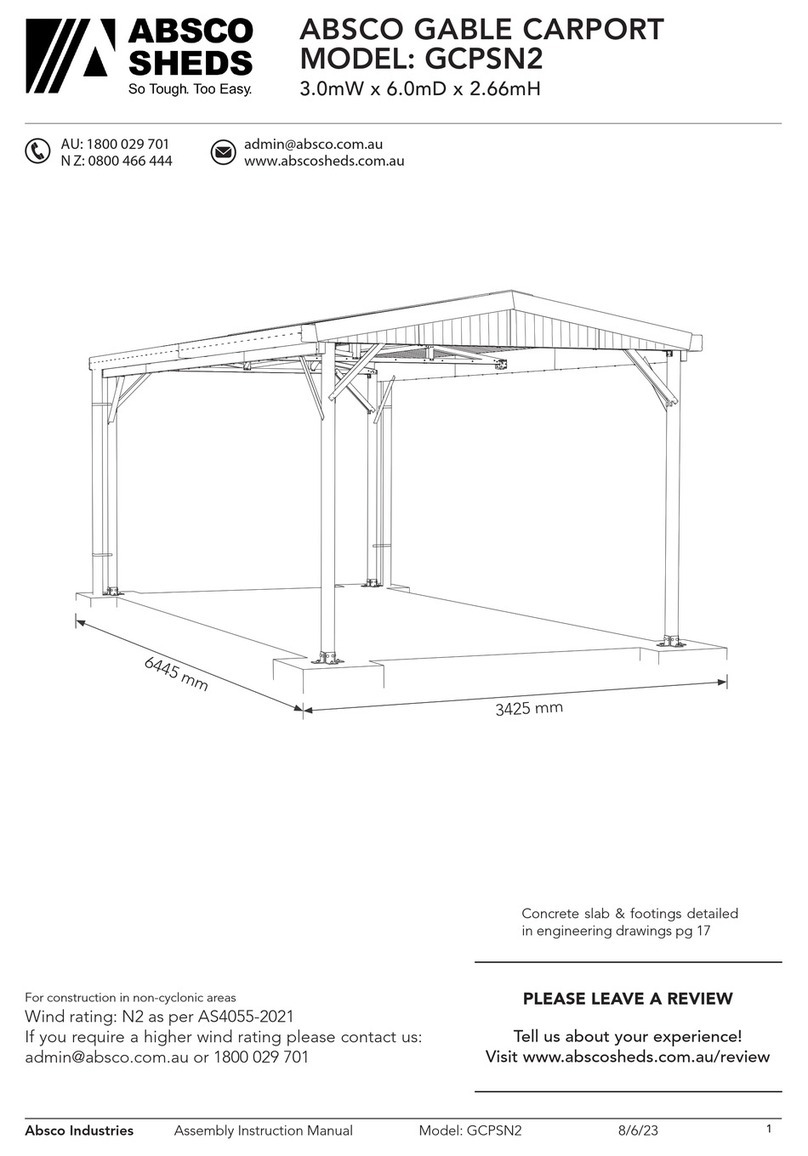

Site Preparation

• Local council approval must be obtained prior

to construction of the carport. Once you have

selected your site you will need to create

and lodge a site plan to your local council or

certifier. You will also have to attach a copy of

the engineering drawings at the back of these

instructions to your site plan.

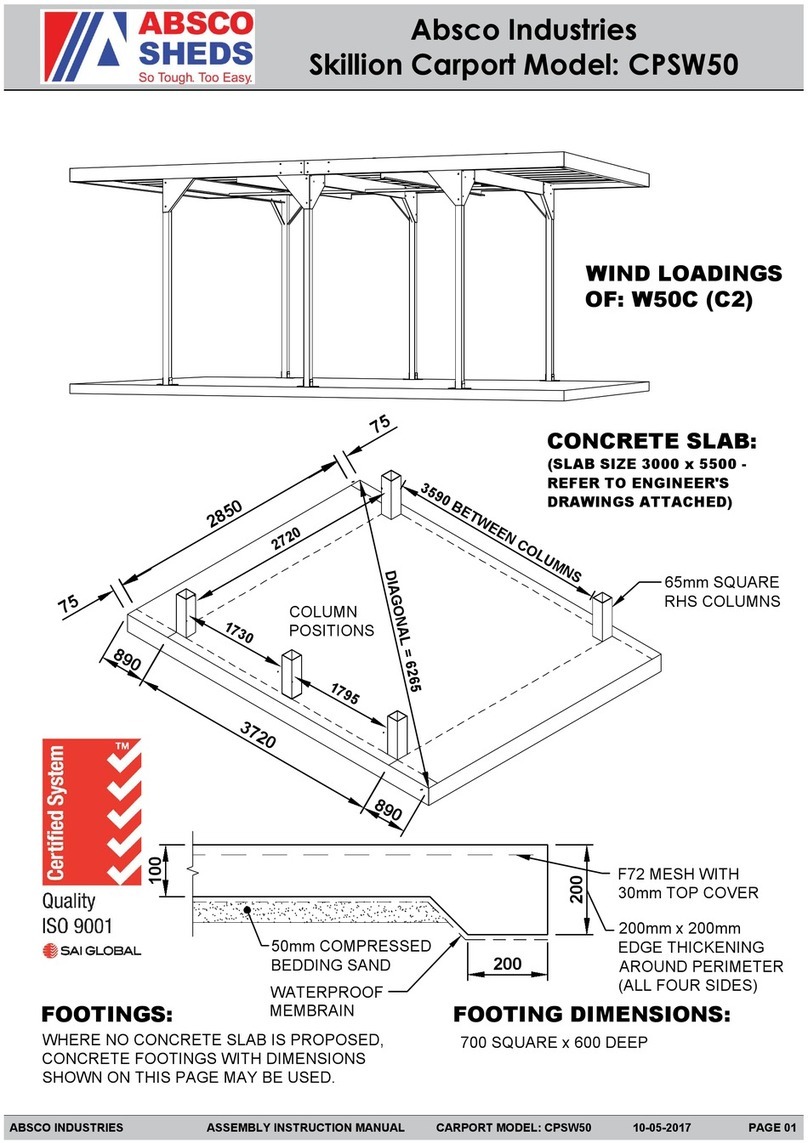

• The site for the carport must be level, refer

to concrete and foundation notes on the

engineering drawing.

General Instructions

• Beforecommencinganyassembly,readthrough

these instructions and engineers drawings in

detail to gain a thorough understanding of

assembly methods and associated details.

• Some components have been pre-punched.

Some 10mm holes will still have to be drilled.

It may be easier to drill a small pilot hole first.

• Measure, and check off all components using

the parts lists on the following pages prior to

commencement. To prevent damage in transit,

some components may be packed inside

others, almost hidden. Carefully examine

inside each component to ensure that you

have located every item. If a discrepancy is

found, contact Absco Industries immediately.

• Don’t cut any components to a different size

unless instructed.

• Three types of tek screws are supplied, take

care to use the right type for the step.

Safety Notes

• The assembly of this product requires some

lifting of heavy objects. Two person lifts are

required.

• Some parts have sharp edges and/or corners.

The use of gloves and safety shoes is highly

recommended. Pay attention to where these

parts can be safely handled, and plan the

handling of these parts before working with

them.

• Drilling sheet metal produces small metal

shavings the use of safety glasses and the

periodic clearing of these shavings throughout

the build is recommended.

• Use the appropriate personal protective

equipment for any tool used during the

assembly.

Tools Required

Some tools required include:

BEFORE STARTING ASSEMBLY

• Electric drill with chuck

• 3 and 10 mm drill bits

• Hammer drill

• 12 mm masonry drill bit

• Mallet

• ‘G’ clamps

• Tape measure

• Socket set

• 17 mm spanner / shifter

• Spirit level

• Water proof sealant (silicone)

• 1.8m ladder

• PVC solvent welding cement.