3

TABLE OF CONTENTS

1. SAFETY INSTRUCTIONS 3

2. INTRODUCTION 4

3. BINDER G1 SPECIFICATIONS 4

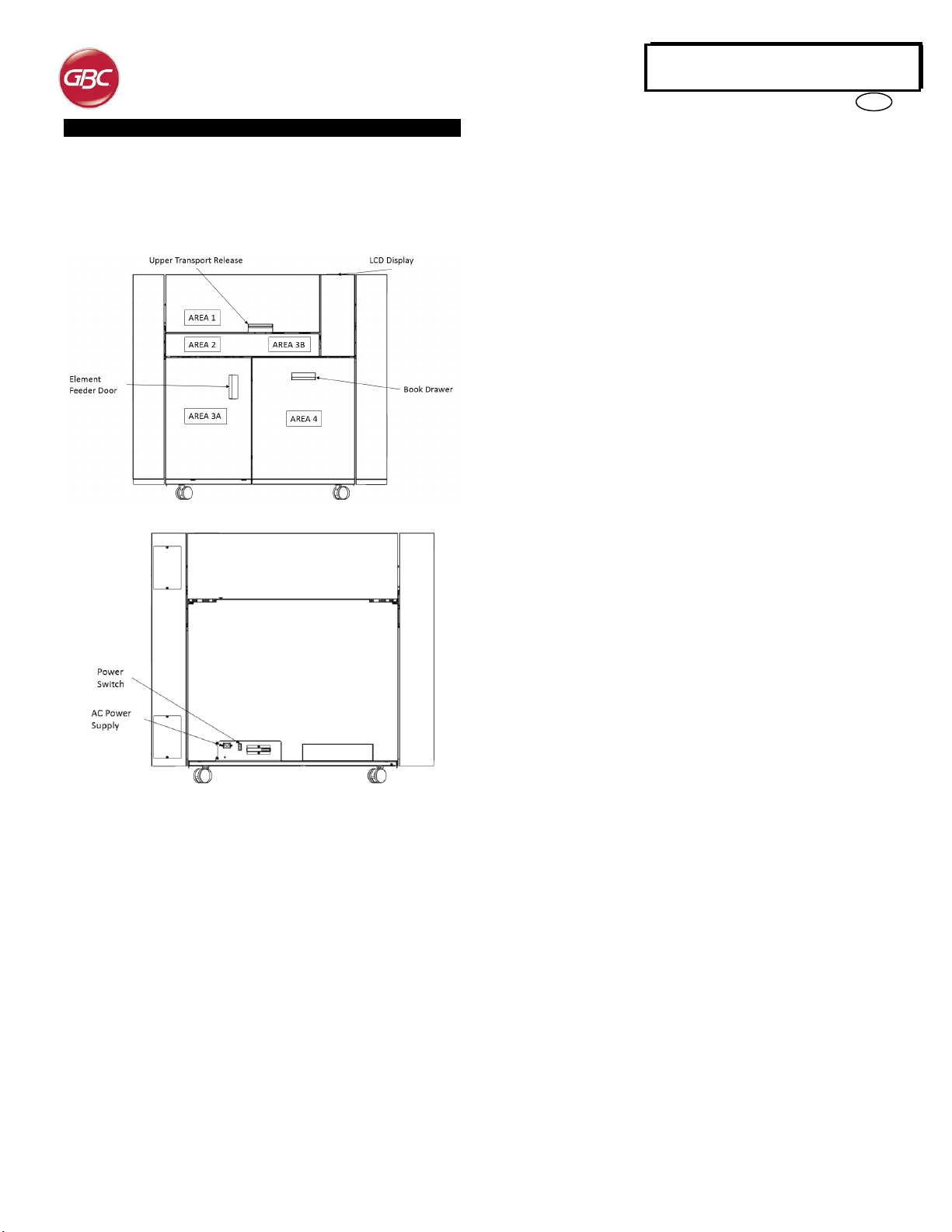

4. BINDER G1 OVERVIEW 5

5. BINDER G1 DIES FOR PUNCH G2 6

6. QUICK START GUIDE 6

7. USER OPERATIONS 6

8. USERDISPLAY 13

9. PROBLEM SOLVING 14

10. SUPPLY INFORMATION 18

11. LCD JAM CODES 19

1. SAFETY INSTRUCTIONS

THE SAFETY OF YOU AND OTHERS IS VERY IMPORTANT TO GBC.

IMPORTANT SAFETY MESSAGES AND INFORMATION ARE

CONTAINED IN THIS MANUAL AS WELL AS ON THE MACHINE

ITSELF. PLEASE MAKE SURE YOU CAREFULLY READ AND

UNDERSTAND ALL OF THESE BEFORE OPERATING THE

MACHINE.

THE SAFETY ALERT SYMBOL PRECEDES EACH SAFETY

MESSAGE IN THIS OPERATION INSTRUCTIONS

MANUAL. THIS SYMBOL INDICATES A POTENTIAL

PERSONAL SAFETY HAZARD THAT COULD HURT YOU

OR OTHERS.

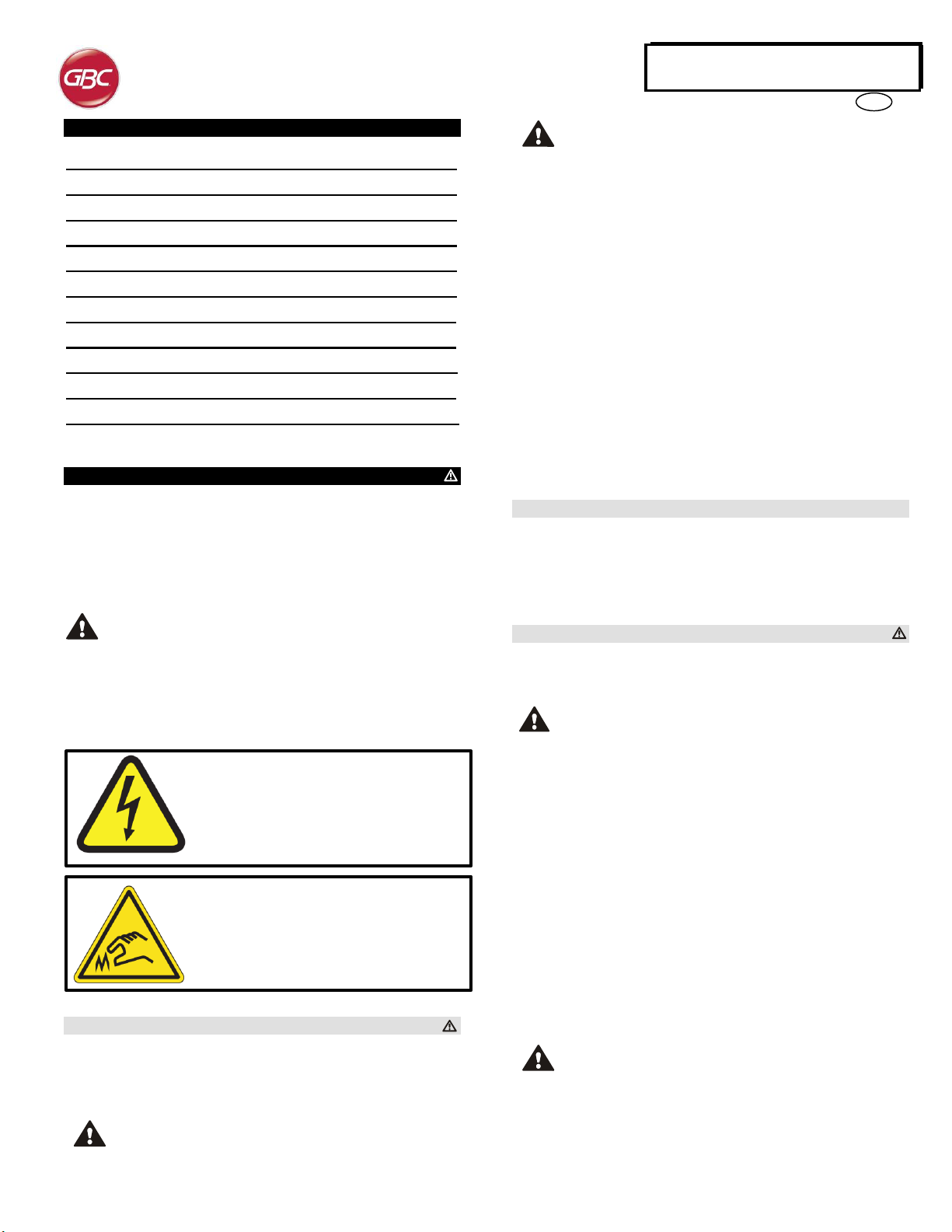

THE FOLLOWING PICTORIALS ARE FOUND ON THE BINDER G1:

This safety symbol means that you might get

seriously hurt or killed if you open the product

and expose yourself to hazardous voltage.

NEVER remove the screwed on covers.

ALWAYS refer service requirements to

qualified service personnel.

This safety symbol means that you may get cut

if you touch the knife positioned behind the

cover it is affixed to. Do not remove this cover

or place fingers behind it.

Important safeguards

Use the BINDER G1 only for its intended purpose of creating bound

books according to the indicated specifications.

Retain this Operation Instructions manual for future use.

CAUTION: THE PRINTER ON/OFF SWITCH DOES NOT

CUT OFF POWER FROM THE BINDER G1.

CAUTION: THE BINDER G1 ON/OFF SWITCH DOES NOT

CUT OFF POWER FROM THE PRINTER.

The BINDER G1 must be connected to a supply voltage

corresponding to the electrical rating of the machine operation

instructions (also listed on the serial number label).

The grounding plug is a safety feature and will only fit into the

proper grounding-type power outlet. If you are unable to insert the

plug into an outlet, contact a qualified electrician to have a suitable

outlet installed.

Do not alter the plug on the end of the cordset (if provided) of the

BINDER G1. It is provided for your safety.

Unplug the BINDER G1 before moving the machine machine or

whenever the machine is not in use for an extended period of time.

Do not operate the BINDER G1 if the machine has a damaged

power supply cord or plug. Do not operate the machine after any

malfunction. Do not operate the machine in case of liquid spills, or

if the machine has been damaged in any other way.

Do not overload electrical outlets beyond their capacity. To do so

may result in fire or electrical shock.

Cleaning

You may clean the exterior of the BINDER G1 using a soft, damp

cloth.

Do not use detergents or solvents as damage to the machine may

occur.

Safety messages

Do not attempt to service your BINDER G1 yourself. Contact an

authorized service representative for any required repairs or major

maintenance for your BINDER G1.

DO NOT REMOVE THE MACHINE’S COVER.

There are NO user-serviceable parts inside the machine. In order to

avoid potential personal injury and/or damage to property or the machine

itself, do not remove the machine’s cover.

FCC NOTE

This equipment has been tested and found to comply with the limits for

a Class A digital device, pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial

environment.

This equipment generates, uses, andcan radiate radio frequencyenergy

and, if not installed and used in accordance with the Operation Manual,

may cause harmful interference with radio communications. Operation

of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the

interference at his/her own expense.

CAN ICES-3 (A)/NMB-3(A)

CAUTION: ANY MODIFICATIONS MADE TO THIS DEVICE

THAT ARE NOT APPROVED BY GBC MAY VOID THE

AUTHOIRITY GRANTED TO THE USER BY THE FCC

AND/OR INDUSTRY CANADA TO OPERATE THIS

EQUIPMENT.