3

Table of Content

Prologue 5

I. Revision History .................................................................................................................................................5

II. Contact Addresses ...........................................................................................................................................5

III. Declaration of Conformity............................................................................................................................6

IV. Warranty .................................................................................................................................................................6

V. Trademarks ...........................................................................................................................................................6

VI. Intended Use........................................................................................................................................................6

VII. License Statements for the Instrument................................................................................................7

VIII. Software License Agreement.....................................................................................................................7

IX. Preamble................................................................................................................................................................7

X. Use of the Instrument Operator’s Manual ..........................................................................................8

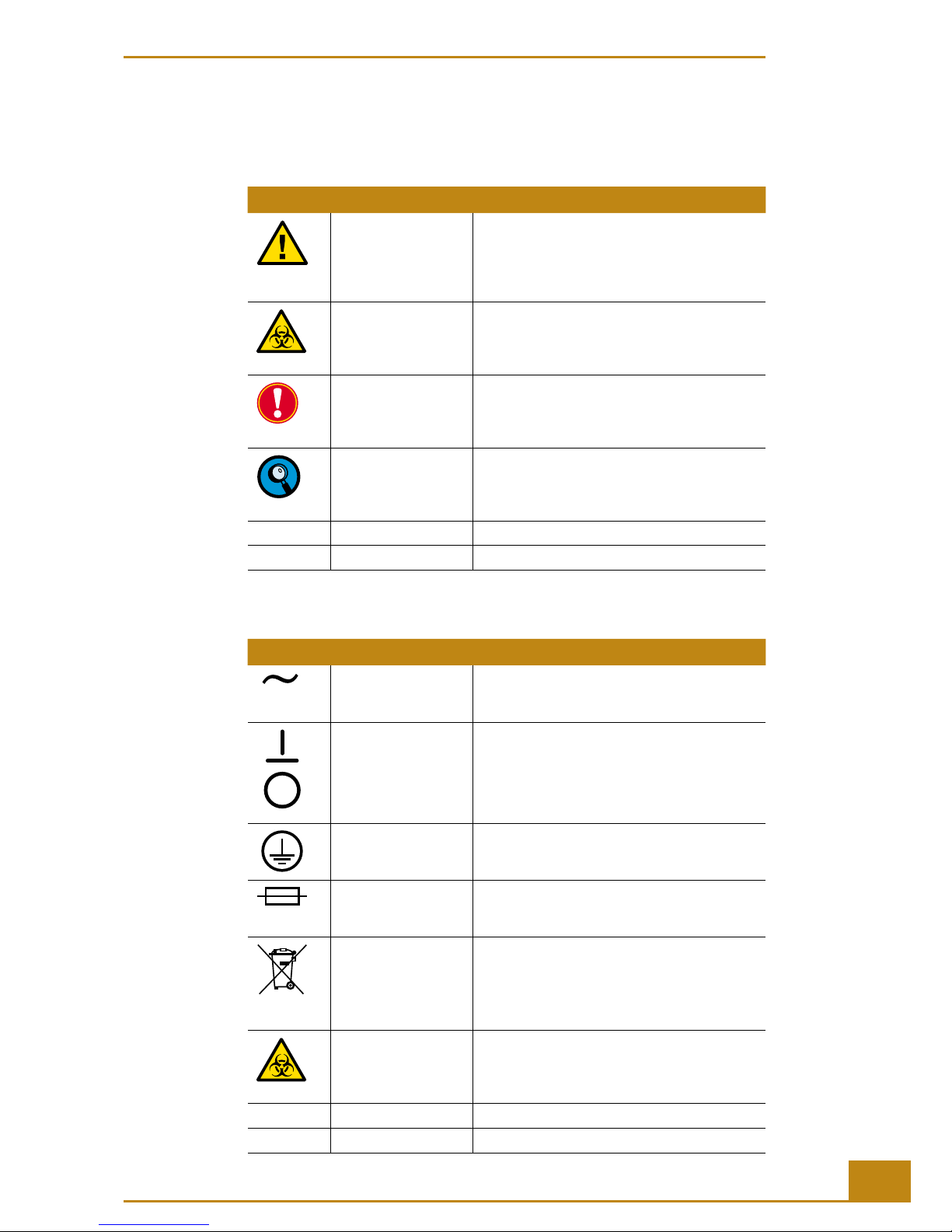

XI. Conventions Used in this Manual............................................................................................................8

XII. Warnings and Precautions........................................................................................................................ 10

XIII. Disposal of the Instrument ....................................................................................................................... 12

A Overview 13

1. Introduction....................................................................................................................................................... 13

1.1 RTCA SP Instrument ......................................................................................................................................... 14

2. Specifi cations of the Instrument ........................................................................................................... 17

2.1 Specifi cations of the RTCA Analyzer.......................................................................................................... 17

2.2 Specifi cations of the RTCA SP Station ...................................................................................................... 17

2.3 Specifi cations of the RTCA Control Unit................................................................................................... 17

2.4 Specifi cations of the E-Plate 96 ................................................................................................................... 18

2.5 Specifi cations of the RTCA Resistor Plate 96.......................................................................................... 18

B System Description 19

1. System Package ............................................................................................................................................. 19

2. System Description....................................................................................................................................... 20

2.1 Description of the RTCA Analyzer............................................................................................................... 21

2.2 Description of the RTCA SP Station ........................................................................................................... 22

2.2.1 Cradle Pocket and Clamp Plate.................................................................................................................... 23

2.2.2 RTCA Protector Shield 96 and RTCA Contact Pins 96......................................................................... 23

2.3 RTCA Control Unit ............................................................................................................................................. 24

2.4 E-Plate 96 and RTCA Resistor Plate 96 ..................................................................................................... 25

2.5 RTCA Frame 96................................................................................................................................................... 26

2.6 RTCA Software.................................................................................................................................................... 27

2.7 RTCA Cleaning and Replacement Equipment ........................................................................................ 27

3. Installation ......................................................................................................................................................... 28

3.1 Installation Warnings........................................................................................................................................ 28

3.2 Unpacking ............................................................................................................................................................ 28

3.3 Space and Power Requirements.................................................................................................................. 29

3.4 Environmental Requirements........................................................................................................................ 29

3.5 Installation of the RTCA SP Instrument .................................................................................................... 29

3.6 Resistor Plate Verifi cation of the RTCA SP Instrument........................................................................ 31