WARNING

LIMITATIONS OF SMOKE OETECTORS

This Smokedetector! sdosigned! oactivatea ndinitiate,e me[genc actio”, b”twill dosoonlywher

2’

used lnconjunctlon w!thothere u! ment. This detector lsdes!gne Iorlnstallation inaccordancewitt

98

NFPAstandards 71,72 A,72B, 2,72 D,and72E,

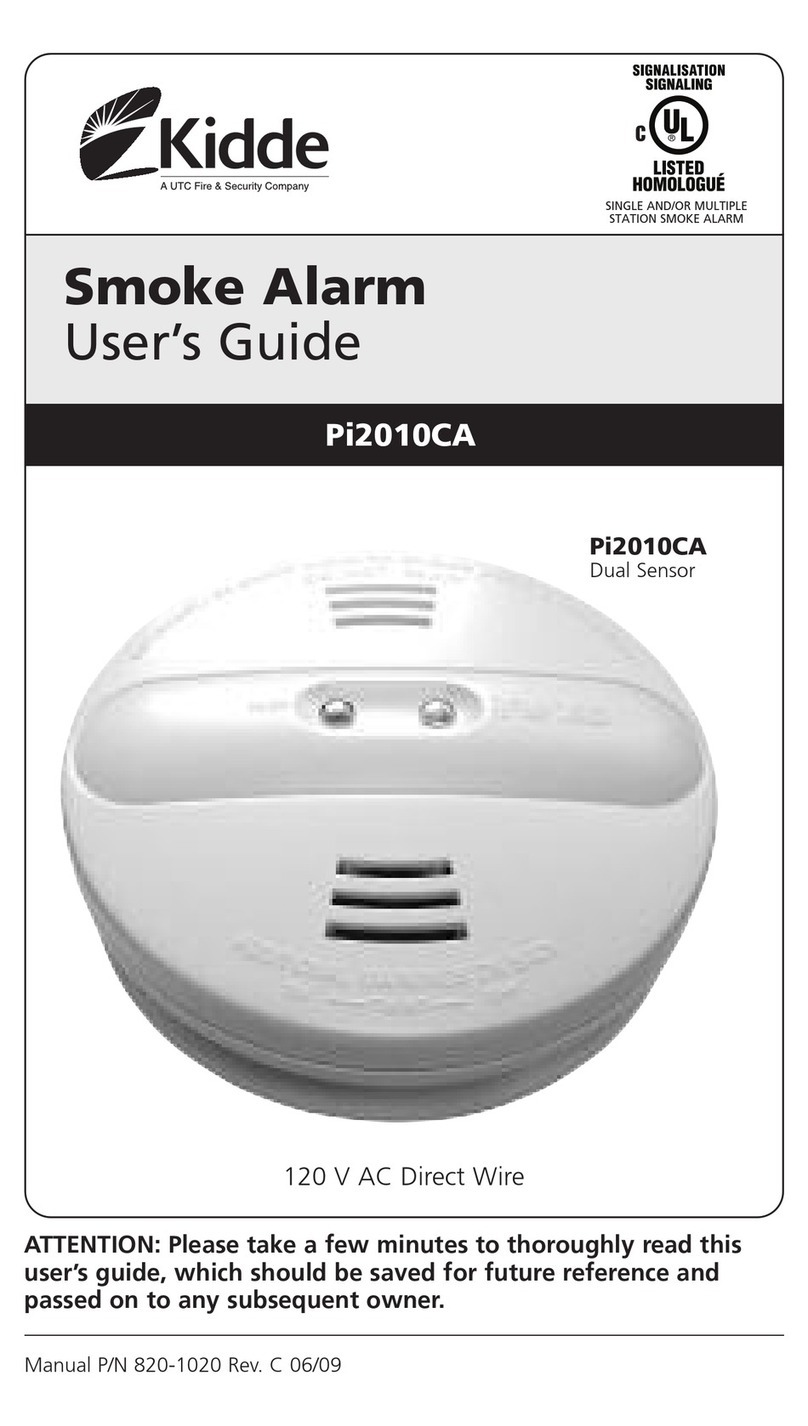

Smoke detectors will network without power. ACor DCpowered smoke detactor$ will notworkil

the power supply is cut off for a“y reason.

Smoke detectOrs will not sense fires which start where smoke does not reach the detectors,

Smoke from fires in chimneys, in walls, on roofs or on the other side of closed doors may not reach the

smoke detector and alarm II,

Adetector maynotdetect allredeveloping onanother level ofabuilding. Forthis r8as0n, d8tec.

tars should be Iocatod on every fevel of abuilding.

Smoke detectors havesensing llmltatlons, too. Ionization detectors offerabroad range fire-sens-

ing capability, but they are better at detecting last, flaming fires than slow smoldering fhes,

Photoefec!ronic detectors s%nsesmoldering fires beNerlhan flaming fires. Because fires develop in

~fferent ways, and are often unpredictable in their grotih, neither type of detector is always best, and

agivendetector maynotalways provide warning of alire. fngeneral, detectors cannot bo expected

to provide warnings for fires resulting from inadequate fire protection practices, violent explosions, e>

taping gas, improper storage of flammable liquids Ike cleaning solvents, other safety hazards, or arson,

Smokedetectors cannot fast forever. Smokodetectors contain electronic pads. Evonthoughdetew

torsare made to last over 10 years, any of these PatiS could fail at any time. Therefore, test your smoke

detector system per NFPA72E atleast semiannually. Cfeanand take care ofyour smoke detectors

regularly. Taking car@ of tha fire detection system you have installed will measurably reduce your

product fiabifbyrisks,

Thisoneyear hmited Warranty isinlie” ofallothe, ex ,essw8rranties, obN atio”$orbati]ities. THERE

ARE NO EXPRESS Warranties WHfCHEXTEN8 SEYONDTHE FA/E HEREOF. ALL IMPLIED

WARRANTIES, OBLIGATIONS OR LIABILfTIES MAOE BY SELLER IN CONNECTION WITH THIS

PRODUCT, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTASILl~, OR FITNESS FOR A

PARTICULAR PURPOSE OR OTHERWISE, ARE LIMITED IN OURATION TO APERfOO OF ONE

YEAR FROM THE DATE OF ORIGfNAL PURCHASE, ANY ACTION FOR BREACH OF ANY WAR.

RANTY, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTASILl~,

MUSTBE SROUGHT WITHIN I8MONTHS OF DATEOFORIGINAL PURCHASE. INNO CASE SHALL

SELLER SE LIASLE TO ANYONE FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR

SREACHOF THIS OR ANY OTHER WARRANTY, EXPRESS OR IMPLIEO, OR uPON ANY OTHER

BASfS OF LIABILITY WHATSOEVER, EVEN IF THE LOSS OR DAMAGE fS CAUSED BY THE

SELLER’S OWN NEGLIGENCE OR FAULT. Somestates donotalfow fimitations onhowlonganim-

ted warranty lasts or tho exclusion or timifatio” of incidental or Consequentialdam~ge~,sothe~b~v~

!mitatio”orexcl”$lo” may not apply to y.”