2612877SBONT-22B

1. Align the slots on the reverse of the Electronics Module with the

tabs on the Enclosure.

2. Slide the Electronics Module on to the tabs and align the Screw Slot

with the threaded hole in the back plate.

3. Secure the Electronics Module using the #6 screw provided

(P/N 3276003003).

Connect Ground

Do not use a knife to cut the opening in the rubber grommets. This may

result in an excessively large hole and compromise the integrity of the

unit by allowing moisture into the unit.

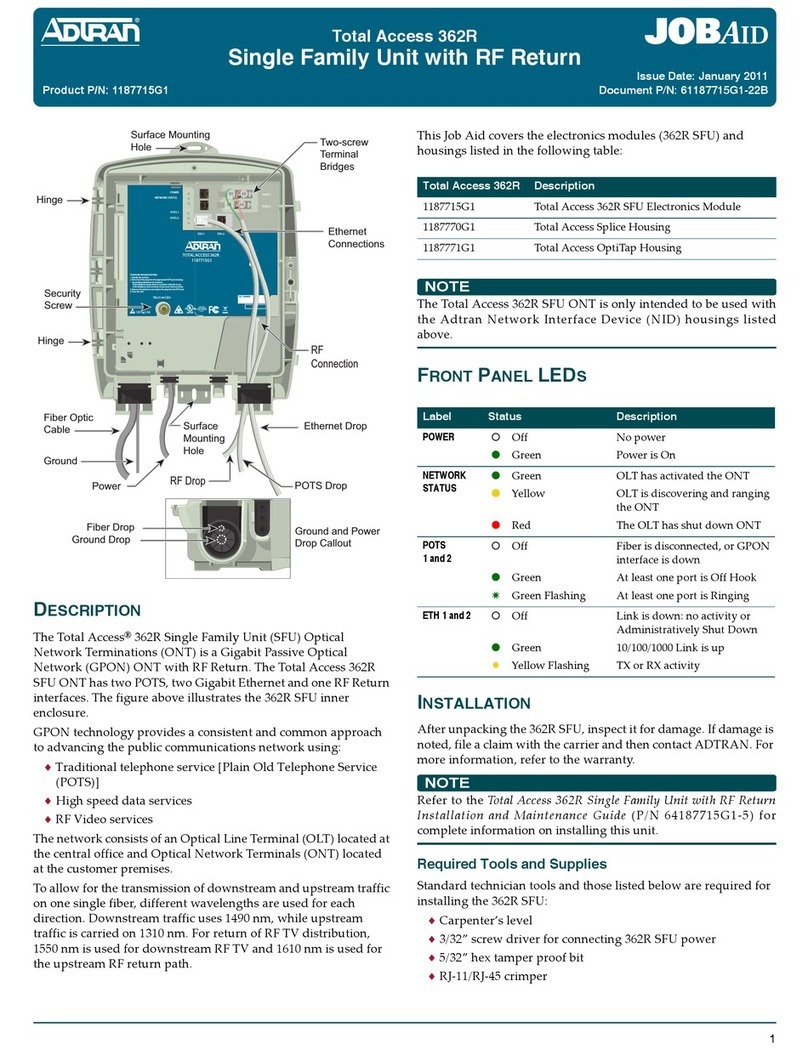

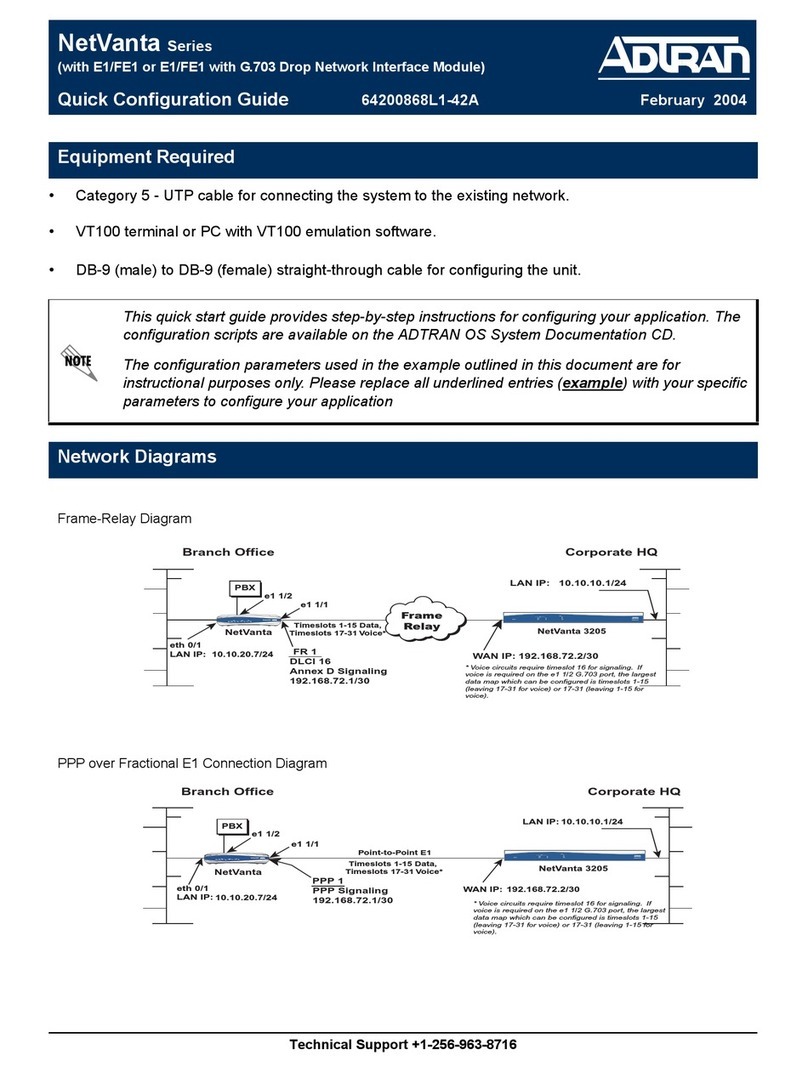

Refer to the illustration on the first page, the illustration below, and the

following steps to connect the ground wire.

1. Remove the rubber grommet from the housing (Step 1).

2. Route a #6 ground wire through the rubber grommet (Step 2).

3. Trim the insulation back 1/2” on the ground wire and attach the

appropriate ground lug.

4. Route the ground wire as shown and attach it to the ground lug just

below the Electronics Module.

5. Replace the rubber grommet in the housing.

6. Route the ground wire 12 inches below finished grade by the

shortest and most direct route to the AC power ground system

Multi Grounded Neutral (MGN) of the customer premises. Ensure

the wire is free of any sharp bends.

7. Attach the ground wire to the subscriber premise with stainless

steel half moon clamps or tie-wrap the ground wire to the riser

conduit of the Buried Fiber Drop.

8. Clean the MGN connector with emery cloth to insure a stable

connection.

9. Attach the ground wire from the ONT to the MGN connector with

the appropriate UL approved ground clamp/fitting.

10. Coat the connection with a metal corrosion preventative.

11. Attach a Warning Ground Tag to this grounding connection.

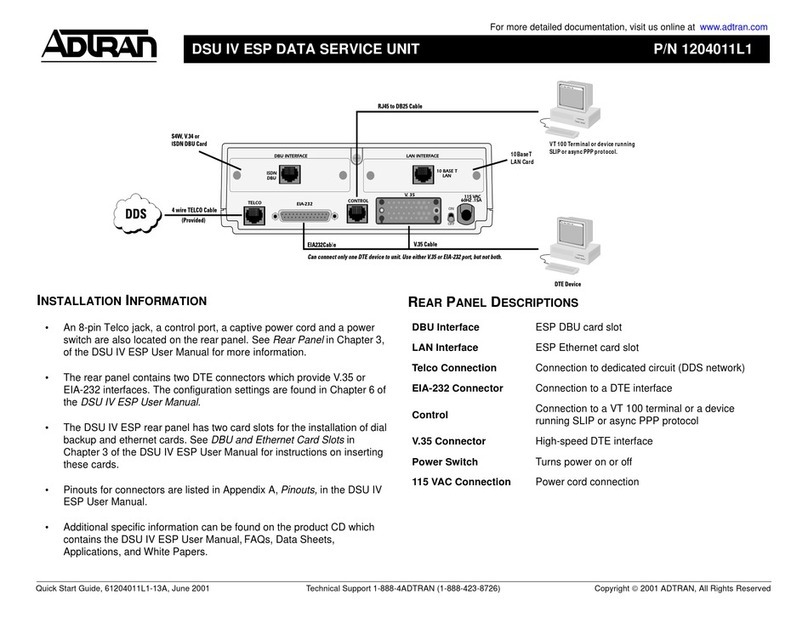

Connect Power/Alarm

Wiring the Power/Alarm connector improperly could damage the SBU.

The ONT is supplied with a 7-pin Power/Alarm connector. To make

connections from the Uninterruptible Power Supply (UPS) to the Power/

Alarm connector, refer to the illustration on the first page, the illustration

below, and Power/Alarm Connector Pin-Outs table below and complete

the following steps:

1. Remove the Power/Alarm Connector by pulling it out of the Elec-

tronics Module.

123

Use this example for all grommet and ber/cable installations.

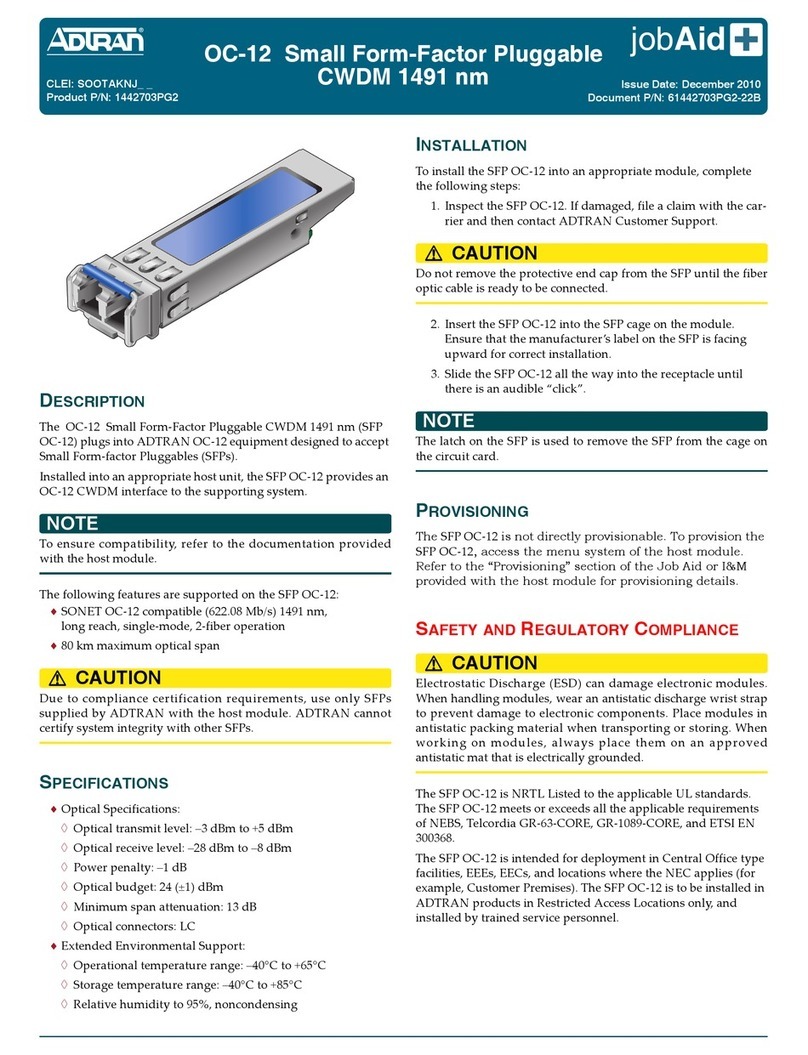

INSTALLATION

Refer to the Total Access 300 Series SBU ONT Installation and Maintenance

Guide (P/N 612877SBONT-5) for complete information on installing these

units both with and without the NID Housing.

After unpacking the ONT, inspect it for damage. If damage is noted, file a

claim with the carrier and then contact ADTRAN. For more information,

refer to the warranty

Required Tools and Supplies

In addition to standard technician tools, you will need the following for

this installation:

Carpenter’s level

3/32” screw driver for connecting ONT power

5/32” hex tamper-proof bit

RJ-45/RJ-11 crimper

A telephony/data communication test set

PON power meter with wavelength filtering

Fiberscope or videoscope

Three #10 screws and appropriate surface anchors for mounting the

ONT

Assorted tie wraps for securing cabling and wiring

For fiber optic connections, you must have the following:

Fiber Optical Fusion Splice Tools

ODC Fiber cleaning tool

Included with the ONT packaging are fiber cable management and strain

relief, a fiber connector, and electronics/optics.

Mount the Enclosure

Refer to the illustration at the top of the next column and complete the

following steps to mount the enclosure:

1. Choose a vertical surface near an approved ground and away from

any water source. The subscriber should have easy access for test-

ing.

2. Use the top and side external mounting holes as a template to mark

fastener locations. Use a level to ensure the unit is level to prevent

warping. For an indoor mount, prepare the mounting surface by

attaching a 3/4 inch plywood board to the wall studs. This provides

long-term stability for the ONT.

3. Pre-drill the marked locations and install fasteners or anchors

appropriate to the mounting surface (each anchor rated to 18 lbs or

8.2 kg minimum).

4. Mount the ONT.

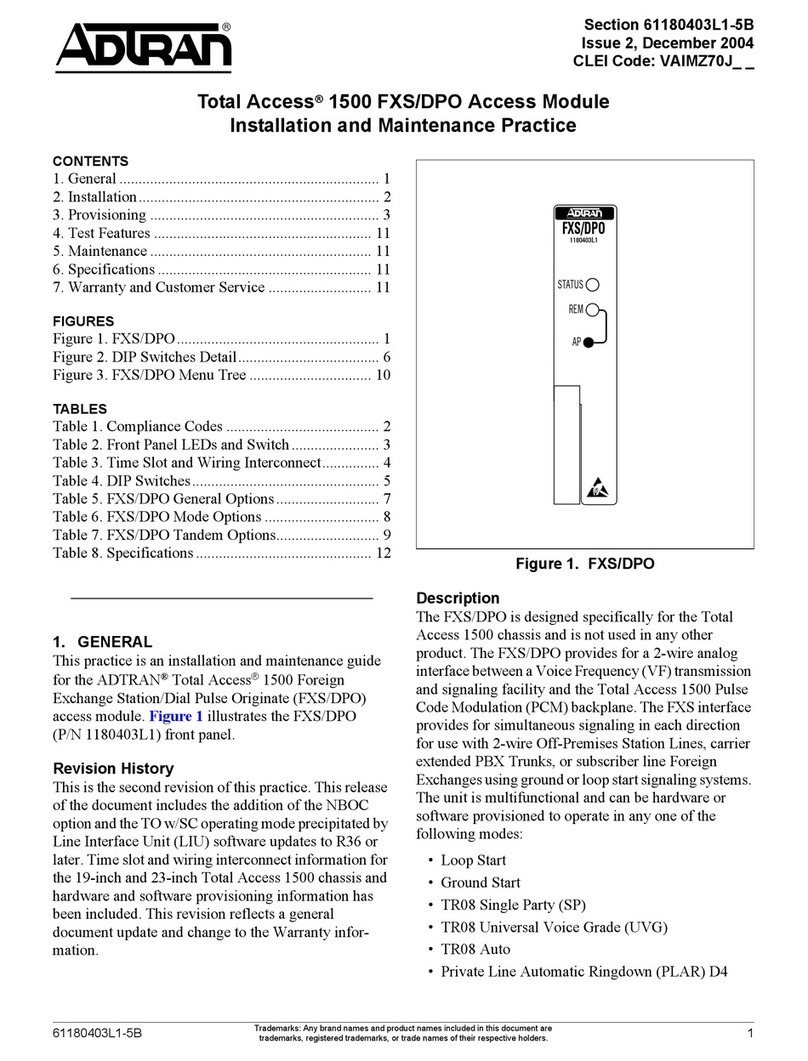

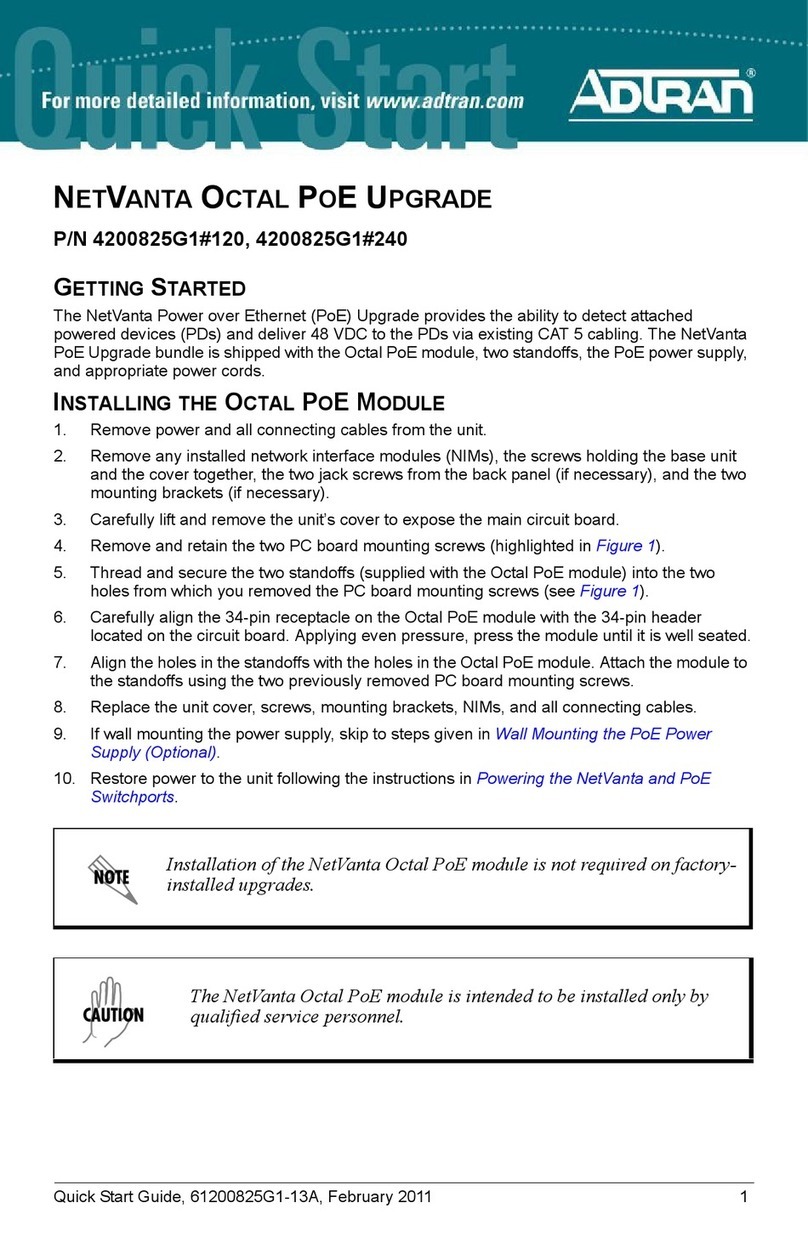

Install the Electronics Module

To install the Electronics Module in the Enclosure, refer to the figure

below and the procedure that follows.

Threaded Hole

Backplate

Tab

Tab

Surface Mounting Hole

Surface Mounting Holes

Left and Right Sides

Screw Slot

FRTEN

LOWBAT

BATMIS

REPBAT

ONBAT

SIGRTN

12VRTN

+12VDC

Key Holes on

Reverse

TELEPHONETROUBLESHOOTING:

1.Identifythe bad line (POTS1-8).

2.Pluganyworking phone into

theappropriate jack.

Ifthetelephoneworks, the unit

isfunctioningnormally.

Ifthetelephonedoes not work,

contact your service provider.

3.Removethetelephone from the

POTS jack.

TOTALACCESS372E

1287723G1

Screw Slot

TELEPHONETROUBLESHOOTING:

1.Identifythe bad line (POTS 1-8).

2.Plugany working phone into

the appropriate jack.

Ifthetelephone works, the unit

isfunctioning normally.

Ifthetelephone does not work,

contactyourservice provider.

3.Removethe teleph one from the

POTSjack.

TOTALACCESS372

1287722G1

Key Holes on

Reverse

TEN

LOWBAT

BATMIS

REPBAT

ONBAT

SIGRTN

12VRTN

+12VDC

P/N 1287722G1 P/N 1287722G2