Instruction manual for vacuum unit

10

22/07/22 Rev:1.0.6

5 PROPER USE OF THE PRODUCT

The vacuum unit has been designed to be installed for the pneumatic transport of pellets or other

biomass fuels with a medium-fine size: it can move a large amount of air into the pipes connected,

allowing the solid fuel to be conveyed and transported together with the air.

This product is suitable for working with biomass fuel such as pellets, olive pomace, crushed

shells of dried fruit, corn, but it cannot work with fuels having excessive dimensions and, in any

case, having lengths over 40 mm or diameter greater than 15 mm.

It is recommended to use only ENplus A1 certified pellet.

The vacuum unit moves the fuel from the main storage tank and convey it to the boiler tank continuously

and automatically: obviously, to achieve this, it is also essential to install the other components of the

system.

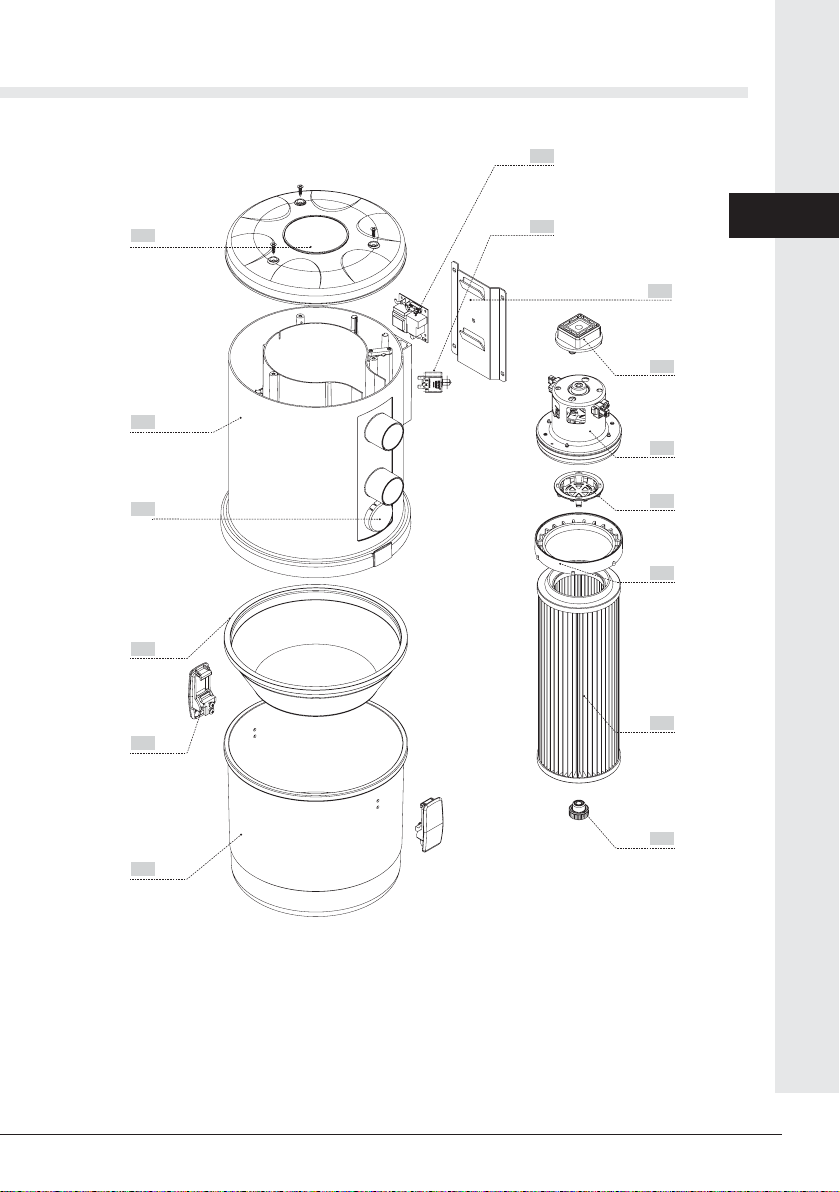

When the vacuum unit is working, it also eliminates the dust from the transported fuel, retaining the

waste in the bucket thanks to the high efficiency filter inside it.

Using the vacuum unit, the fuel transport system can be combined with a central vacuum system with

one or more cleaning sockets. In the catalog you can find all the accessories needed for this purpose

(see chapter 7).

The product is suitable to serve boilers with a maximum power of 100 Kw/h and with a fuel consumption

lower than 25 kg/h.

The vacuum unit cannot be included in any fuel transport system that involves the recirculation of

suctioned air to the storage tank (two pipe system).

6 INSTALLATION

It is the installer’s responsibility to verify the presence of any risk of danger in the installation

area and to determine the suitability in accordance with both the applicable laws and the product

characteristics described in this manual.

The installer must also comply with the requirements of this manual as well as inform the user of the

operation and maintenance of the installed products and report any dangers related to their use.

It is necessary to leave a free space of adequate size all around the product, in order to permit any

repair, maintenance or inspection operation.

The product should not be exposed to atmospheric agents and should not be installed in areas subject

to high humidity, possible flooding, high temperatures and dust presence.

6.1 Instruction for the installation of systems

Consider that in pneumatic fuel transport systems there are two different types of pipe features:

A sections of pipes where only air and eventually dust pass through

B- sections of pipes where both air and fuel pass through

Mandatory all sections of piping through which the fuel passes must be made with PU or steel pipe and they

must be connected to be antistatic.

We remind you that the lengths of the various pipe sections described in our manuals and catalogs are pu-

rely indicative: when we speak of “available length” we mean the total development of the various sections.

It is always advisable to make mainly straight and horizontal piping sections and, in any case, with the least

number of changes of direction and vertical paths.

For all the sections where fuel passes, it is recommended to follow these simple rules:

the maximum length allowed for the various sections of piping depends on the components chosen for your