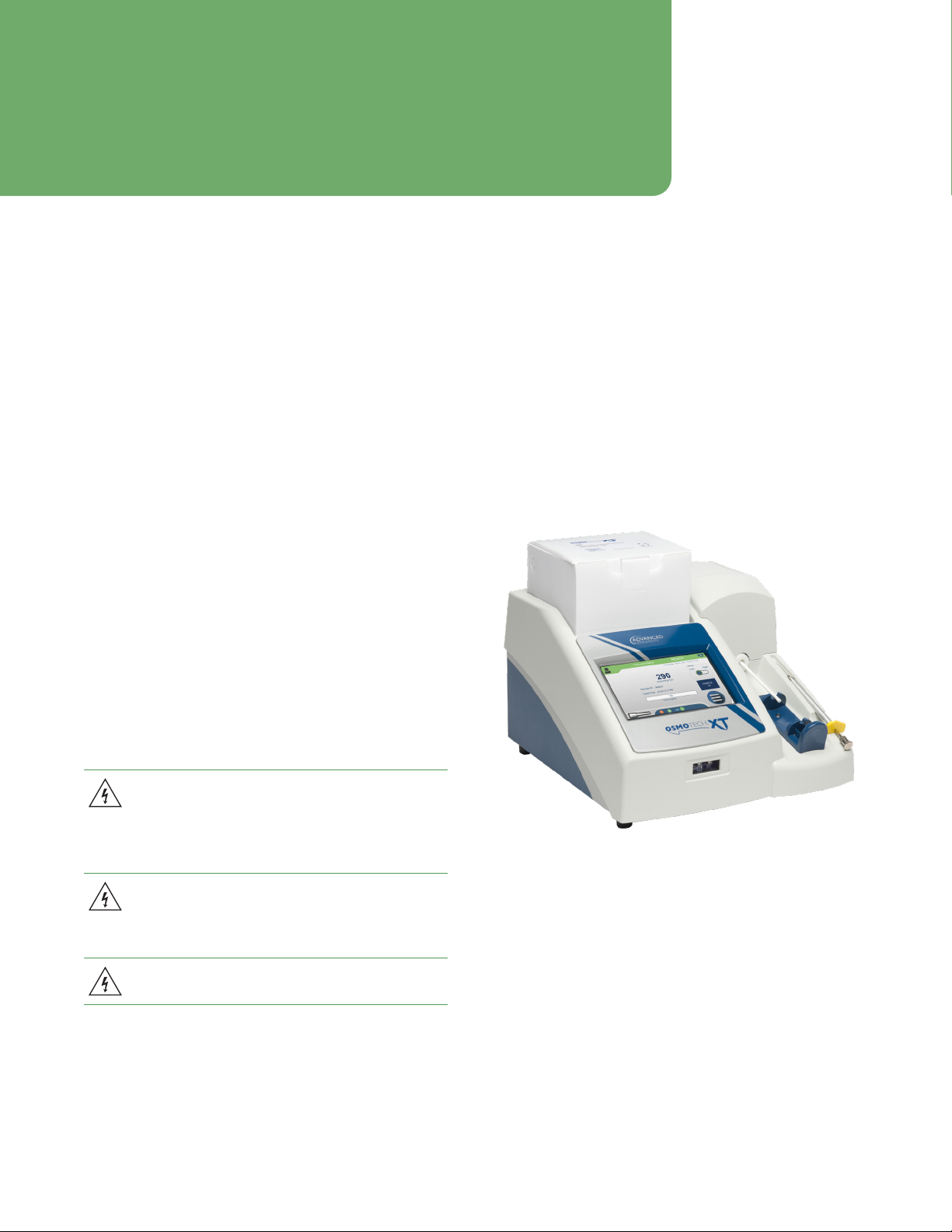

OsmoTECH XT Single-Sample Micro-Osmometer Service Guide 3

Contents

Contacting Advanced Instruments..............................5

Supplies, standards and controls.................................6

Safe use..............................................................................7

Foreword.......................................................................... 10

Chapter 1: Overview ....................................................... 11

1.1 Front view ............................................................................................11

1.2 Rear view..............................................................................................11

1.3 Mechanical description ...................................................................11

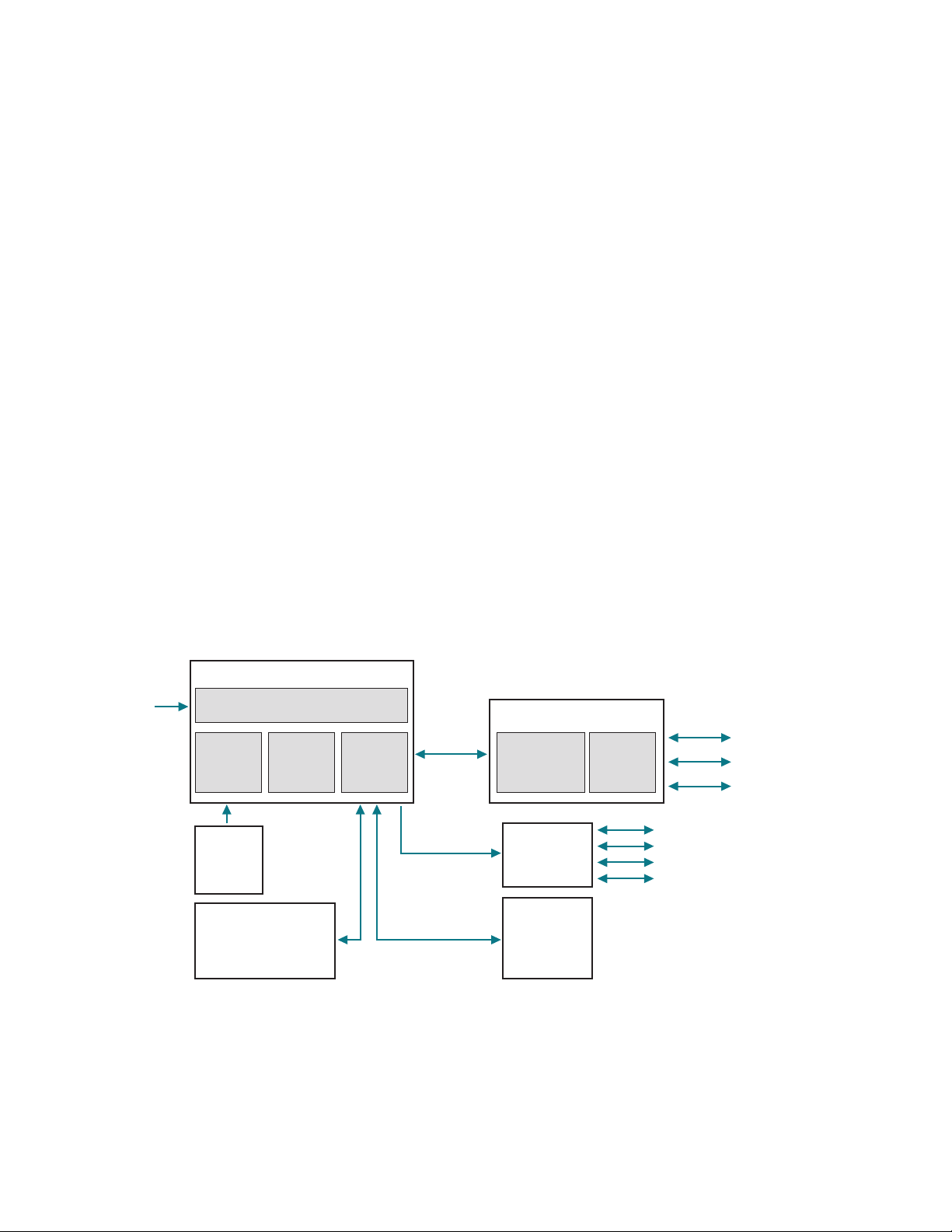

1.4 Electrical description......................................................................12

1.5 Capturing screens to help with troubleshooting.................13

Chapter 2: Setup ............................................................ 14

2.1 Location requirements ...................................................................14

2.2 Placing the Micro-Sample Test Kit on the instrument........14

2.3 Connecting to a network (optional) .........................................15

2.4 Powering up the instrument ........................................................15

Setting the installation date ..................................................... 15

Chapter 3: Calibration................................................... 16

3.1 Factory calibration...........................................................................16

3.2 When to recalibrate.........................................................................16

3.3 Configuring the operating range ...............................................16

3.4 Calibration procedure.....................................................................17

3.5 Canceling calibration ......................................................................18

Canceling the test in progress.................................................18

Canceling the entire calibration..............................................18

3.6 Calibration errors..............................................................................19

Chapter 4: Diagnostics................................................ 20

4.1 Accessing the Diagnostics menu ..............................................20

4.2 Testing A/D functions....................................................................20

4.3 Checking consumables status.....................................................21

4.4 Testing the sample probe.............................................................22

4.5 Testing the barcode scanner.......................................................22

4.6 Viewing and exporting events....................................................22

Filtering the Events list..............................................................23

4.7 Testing the printer...........................................................................24

4.8 LCD .......................................................................................................24

4.9 Testing the solenoid .......................................................................24

4.10 Logging instrument maintenance and repair.......................24

Logging routine instrument cleaning .................................. 25

Logging preventative maintenance......................................25

Logging repair information .....................................................26

Chapter 5: Configuring settings.................................27

5.1 The Settings screen........................................................................ 27

Default user accounts................................................................ 27

5.2 Setting the date and time............................................................ 27

Synchronizing to a network time server ............................ 27

Entering the date and time manually ..................................28

5.3 Changing the language.................................................................28

5.4 Changing the probe resistance..................................................28

5.5 Setting up networking communications................................29

Configuring a LAN connection...............................................29

Configuring OPC-UA communication ................................ 30

Enabling the web server.......................................................... 30

Viewing and printing data from the webserver...............31

Connecting to a LIS....................................................................32

Send-results mode......................................................................32

5.6 Managing instrument data...........................................................32

Configuring data export ...........................................................32

Exporting data manually ..........................................................33

Backing up the database..........................................................33

Backing up databases manually............................................34

Configuring data recording and clearing database

tables................................................................................................35

Importing/restoring database records................................35

Exporting a single result ..........................................................37

5.7 Assigning user restrictions .......................................................... 37

Changing password settings...................................................38

Configuring testing access ......................................................38

Configuring audits of test results (approvals, reviews,

and comments) ............................................................................39

Setting timeouts ......................................................................... 40

5.8 Updating the system..................................................................... 40

Resetting instrument system settings..................................41

Configuring V&V settings..........................................................41