19 The Advanced®Model 3900 Service Manual

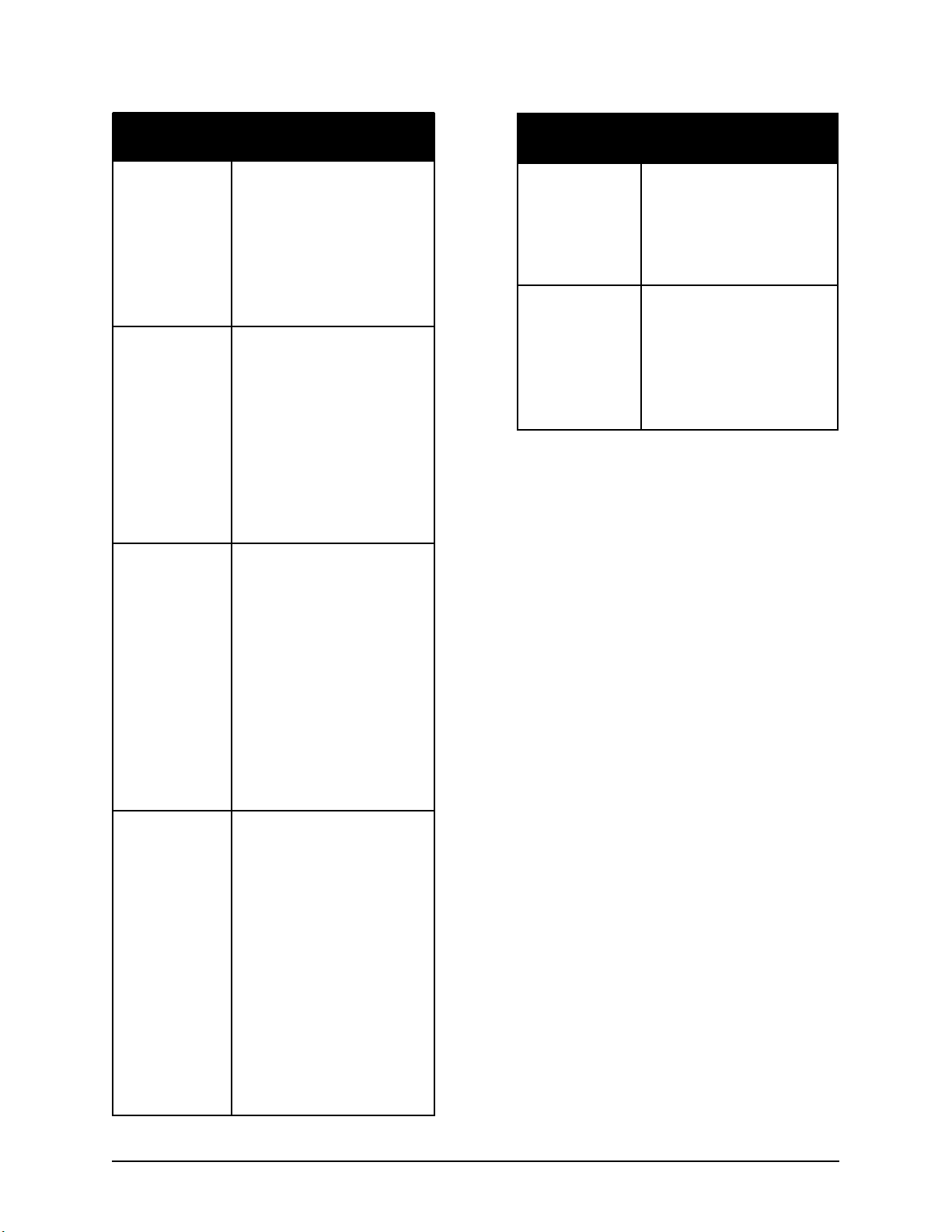

Replacement Parts

Supplies & Accessories

100 mOsm/kg Calibration Standard

(10 5-mL ampules) . . . . . . . . . . . . . . .3LA011

500 mOsm/kg Calibration Standard

(10 5-mL ampules) . . . . . . . . . . . . . . .3LA051

900 mOsm/kg Calibration Standard

(10 5-mL ampules) . . . . . . . . . . . . . . .3LA091

1500 mOsm/kg Calibration Standard

(10 5-mL ampules) . . . . . . . . . . . . . . .3LA151

3000 mOsm/kg Calibration Standard

(10 5-mL ampules) . . . . . . . . . . . . . . .3LA301

100 mOsm/kg Calibration Standard

(110-mL bottle) . . . . . . . . . . . . . . . . . .3LA010

500 mOsm/kg Calibration Standard

(110-mL bottle) . . . . . . . . . . . . . . . . . .3LA050

900 mOsm/kg Calibration Standard

(110-mL bottle) . . . . . . . . . . . . . . . . . .3LA090

1500 mOsm/kg Calibration Standard

(110-mL bottle) . . . . . . . . . . . . . . . . . .3LA150

Clinitrol™ 290 Reference Solution

(10 5-mL ampules) . . . . . . . . . . . . . . .3LA029

Osmolality Linearity Set (5 levels) . . . . . .3LA028

Protinol® Near Serum Reference

(3 levels) . . . . . . . . . . . . . . . . . . . . . .3 A028

Renol™ Urine Osmolality Controls

(2 levels) . . . . . . . . . . . . . . . . . . . . . . .3LA085

Evaporation Cover . . . . . . . . . . . . . . . . . . .390330

Fluid Fill Plug (vented) . . . . . . . . . . . . . . .4C3448

Sample Tubes, 0.2 mL/0.3 mL . . . . . . . . .3LA825

Sample Tube Cassettes, #1-5 . . . . . . . . . . .4C3050

Sample Tube Cassettes, #6-10 . . . . . . . . . .4C3060

Sample Tube Cassettes, #11-15 . . . . . . . . .4C3070

Sample Tube Rack . . . . . . . . . . . . . . . . . . .3LA846

Calibration Cassette . . . . . . . . . . . . . . . . . .4C3040

Heat Transfer Fluid . . . . . . . . . . . . . . . . . .3DA811

Cooling Reservoir Fill Funnel . . . . . . . . . .4C3308

Thermal Printer Paper . . . . . . . . . . . . . . . .FLA835

Paper Roll Holder . . . . . . . . . . . . . . . . . . .FL0408

Printer aintenance Kit . . . . . . . . . . . . . . .FL0425

Box of 100 Probe Wipers . . . . . . . . . . . . . .4C3840

10 Pack Drip Return Wipers . . . . . . . . . . . .---------

Disposable Air Filters . . . . . . . . . . . . . . . .3D2340

Operator/Supervisor Keys . . . . . . . . . . . . .3D3185

Power Cord (specify voltage and country) . . . .--------

Stir/Freeze Wire . . . . . . . . . . . . . . . . . . . . .3C2243

Probe/Stir Alignment Kit . . . . . . . . . . . . . .3LA700

Serial Port Computer Cable with DB9S:

3- eter Shielded RS-232 . . . . . . . . . .330053

6- eter Shielded RS-232 . . . . . . . . . .330056

9- eter Shielded RS-232 . . . . . . . . . .330059

Barcode Reader with Stand . . . . . . . . . . . .390016

Service anual . . . . . . . . . . . . . . . . . . . . .3905S

User’s Guide . . . . . . . . . . . . . . . . . . . . . . . . . .3905

How to order:

To order parts, supplies and accessories, contact

the Advanced Instruments Customer Service.

•(800) 225-4034 (toll-free within the USA and

Canada)

•+US (781) 320-9000 (elsewhere)

•+US (781) 320-3669 (fax)

Automatic Calibration Cassettes . . . . . . . .4C3040

Back Panel Upgrade Kit . . . . . . . . . . . . . .4C3008

Block Probe . . . . . . . . . . . . . . . . . . . . . . . .390340

Cassette Labels . . . . . . . . . . . . . . . . . . . . .4C3039

Cassette Pusher Arm . . . . . . . . . . . . . . . . . .390437

Cassette Pusher Arm otor Assembly . . .4C3420

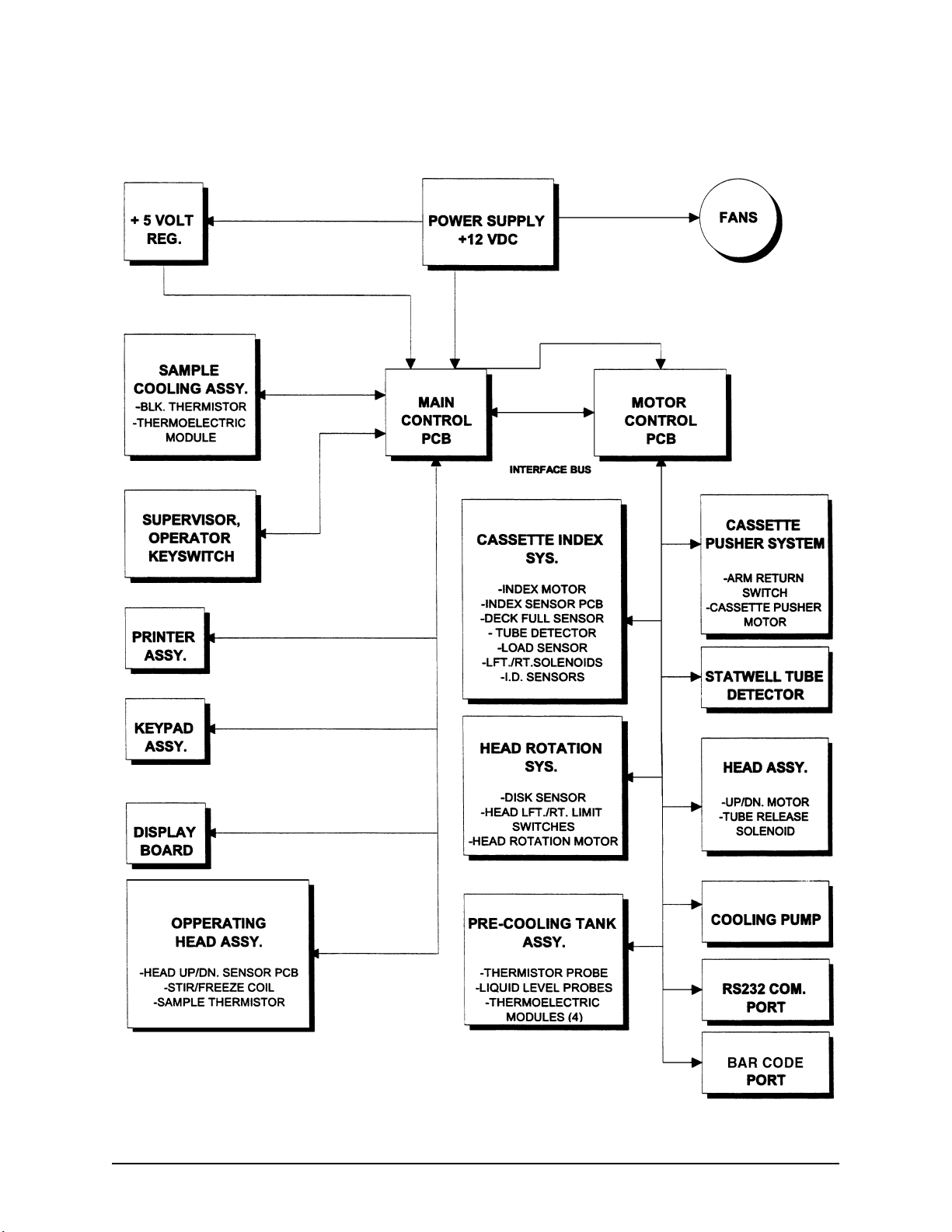

Cooling Fans . . . . . . . . . . . . . . . . . . . . . . .4C3121

Cooling Reservoir Assembly . . . . . . . . . . .4C3310

Disk Sensor/ ounting Block . . .4C3413/4C3436

Display Kit . . . . . . . . . . . . . . . . . . . . . . . . .4C3851

Drip Return Well Assembly . . . . . . . . . . . .390843

Fluid Pump Diaphragm . . . . . . . . . . . . . . .4C3190

Harness Upgrade . . . . . . . . . . . . . . . . . . . .4C3149

Head Drive Assembly . . . . . . . . . . . . . . . .4C3440

Head Rotation Idler Gear . . . . . . . . . . . . . .4C3416

Heat Transfer Fluid Pump . . . . . . . . . . . . .4C3189

Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . .4C3511

andrel . . . . . . . . . . . . . . . . . . . . . . . . . . .390444

PCB ( ain Control Board) . . . . . . . . . . . .390600

PCB ( otor Control Board) . . . . . . . . . . .4C3450

Power Supply . . . . . . . . . . . . . . . . . . . . . . .4C3951

Print Head Assembly . . . . . . . . . . . . . . . . .4C3175

Printer PC Board . . . . . . . . . . . . . . . . . . .4C3170R

Printer PC Board Upgrade Kit . . . . . . . . . .4C3169

Probe Alignment Tool . . . . . . .3LA703/3LA703R

Reservoir Tank Probe . . . . . . . . . . . . . . . .4C3340

Sample Cooling Well . . . . . . . . . . . . . . . . .390300

Sample Probe (stainless steel) . . . . . . . . .4C3700

Slot Cover . . . . . . . . . . . . . . . . . . . . . . . . .4C3427

Transistor . . . . . . . . . . . . . . .PCB520R/PCB522R

Tube Gripper . . . . . . . . . . . . . . . . . . . . . . .4C3446

Tube Sensor . . . . . . . . . . . . . . . . . .390026/390028

Yoke, Clapper & Coil .3LH230/3C2241R/3D2404