Acknowledgments

Written By: Jen Sprandel

Edited By: Annie Braddock

Reviewed By: Stuart Baker

Copyright

2014 (Ver. 8), 2010 (Ver. 7) 2009 (Ver. 6), 2007 (Ver. 5), 2006 (Ver. 4), 2003 (Ver. 3), 2001 (Ver. 2), 1995 (Ver. 1), Advanced

Poly-Packaging, Inc. (APPI). All rights reserved.

This manual and the program operating the equipment described in it are copyrighted. You may not copy this manual in whole or

part without the consent of Advanced Poly-Packaging, Inc.

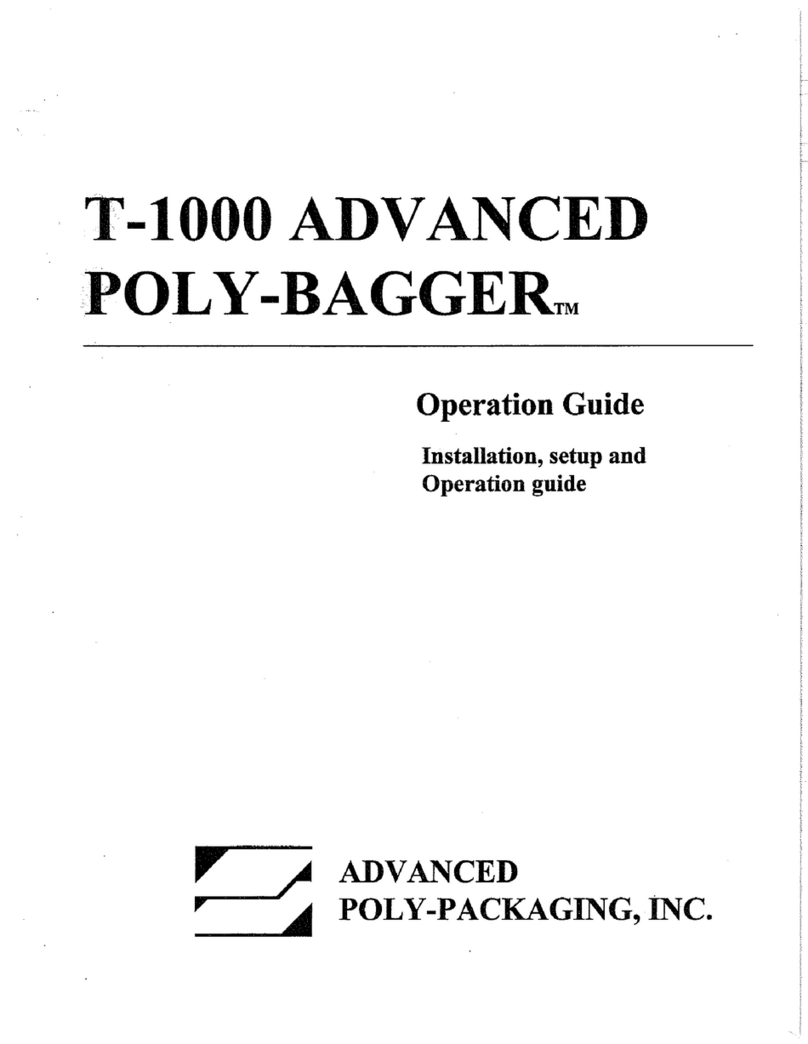

All information pertaining to the promotion, sale, distribution, operation and maintenance of the T-1000-S14 ADVANCED

POLY-BAGGER including this manual, drawings, schematic, wiring diagrams, VHF video tapes, brochures, specification sheets,

figures, charts, or any other information, due to its proprietary design and manufacture remain the property of Advanced Poly

Packaging, Inc. Unauthorized duplication, distribution or disclosure to third parties without the expresses permission of

Advanced Poly-Packaging, Inc. is strictly prohibited.

Trademarks

T-1000-S14 is a trademark of Advanced Poly-Packaging, Inc. Advanced Poly-Packaging, Inc. owns also the following

trademarks: Advanced Poly-Bags, Advanced Poly-Bagger, Seal-a-Print, Roll-a-Print, Twin-Seal, Teflon Shield, Advanced Poly-

Pack, Advanced Poly-Bag, Advanced Bag.

Limited Warranty and Disclaimer

Warranty period is 12 months or 1,000,000 cycles whichever comes first. The warranty commences on the date of delivery of the

equipment to the Purchaser. APPI warrants to the Purchaser that the equipment is free from defects in workmanship or material

under normal use and service. During the warranty period, APPI agrees to repair or replace, at its sole option, without charge to

Purchaser, any defective component part of the equipment. To obtain service, Purchaser must return the equipment or component

to APPI or an authorized APPI distributor or service representative in an adequate container for shipping. Any shipping charges,

insurance, or other fees must be paid by Purchaser and all risk for the equipment shall remain with Purchaser until such time as

APPI takes receipt of the equipment. Upon receipt, APPI, the authorized distributor or service representative will promptly repair

or replace the defective component and then return the equipment or component to Purchaser, shipping charges, insurance and

additional fees prepaid. APPI may use reconditioned or like new parts or units, at its sole option, when repairing any component

or equipment. Repaired products shall carry the same amount of outstanding warranty as from original purchase. Any claim

under the warranty must include a dated proof of delivery. In any event, APPI's liability for defective components or equipment is

limited to repairing or replacing the components. This warranty is contingent upon proper use of the equipment by Purchaser and

does not cover: expendable component part such as Teflon, thermocouple wire, heater cartridge, rollers, bushings, and the like; or

if damage is due to accident, unusual physical, electrical or electromechanical stress, neglect, misuse, failure of electric power,

water damage (from airlines), improper environmental conditions, transportation, tampering with or altering of the equipment,

packaging of corrosive or contaminating products or other products damaging to components, and equipment or components not

owned or in the possession of original Purchaser. APPI will not be liable for loss of production, profits, lost savings, special,

incidental, consequential, indirect or other similar damages arising from breach of warranty, breach of contract, negligence, or

their legal action even if APPI or its agent has been advised of the possibility of such damages or for any claim brought against

the Purchaser by another party. This warranty allocates risks of equipment failure between Purchaser and APPI. APPI's pricing

reflects this allocation of risk and the limitations of liability contained in this warranty. The warranty set forth above is in lieu of

all other express warranties, whether oral or written. The agents, employees, distributors and dealers of APPI are not authorized

to make modifications to this warranty, or additional warranties binding on APPI. Accordingly, additional statements such as

dealer advertising or presentations, whether oral or written, do not constitute warranties by APPI and should not be relied upon.

Warranty on equipment is considered void when outstanding balances become delinquent (over 30 days late - 60 days after ship

date). Equipment Integration to other Equipment: APPI assumes no responsibility for the integration of its products to other

products or within a system unless APPI performs the integration, testing and provides the results of the tests to the purchaser in

writing. Furthermore, APPI assumes no responsibility for bag sizing whether suggested or recommended.

.