Inappropriate use of the machine will immediately void all

contractually-agreed warranty rights and may constitute a potential

risk to individuals and property.

1.2 Technical assistance and machine maintenance

All technical assistance operations, preventive maintenance or breakdown

repair operations not described in this manual must be performed by

employees of the authorized Dealer or by personnel previously authorized by

this Dealer.

Failure to follow these instructions shall immediately void all

contractually-agreed warranty rights.

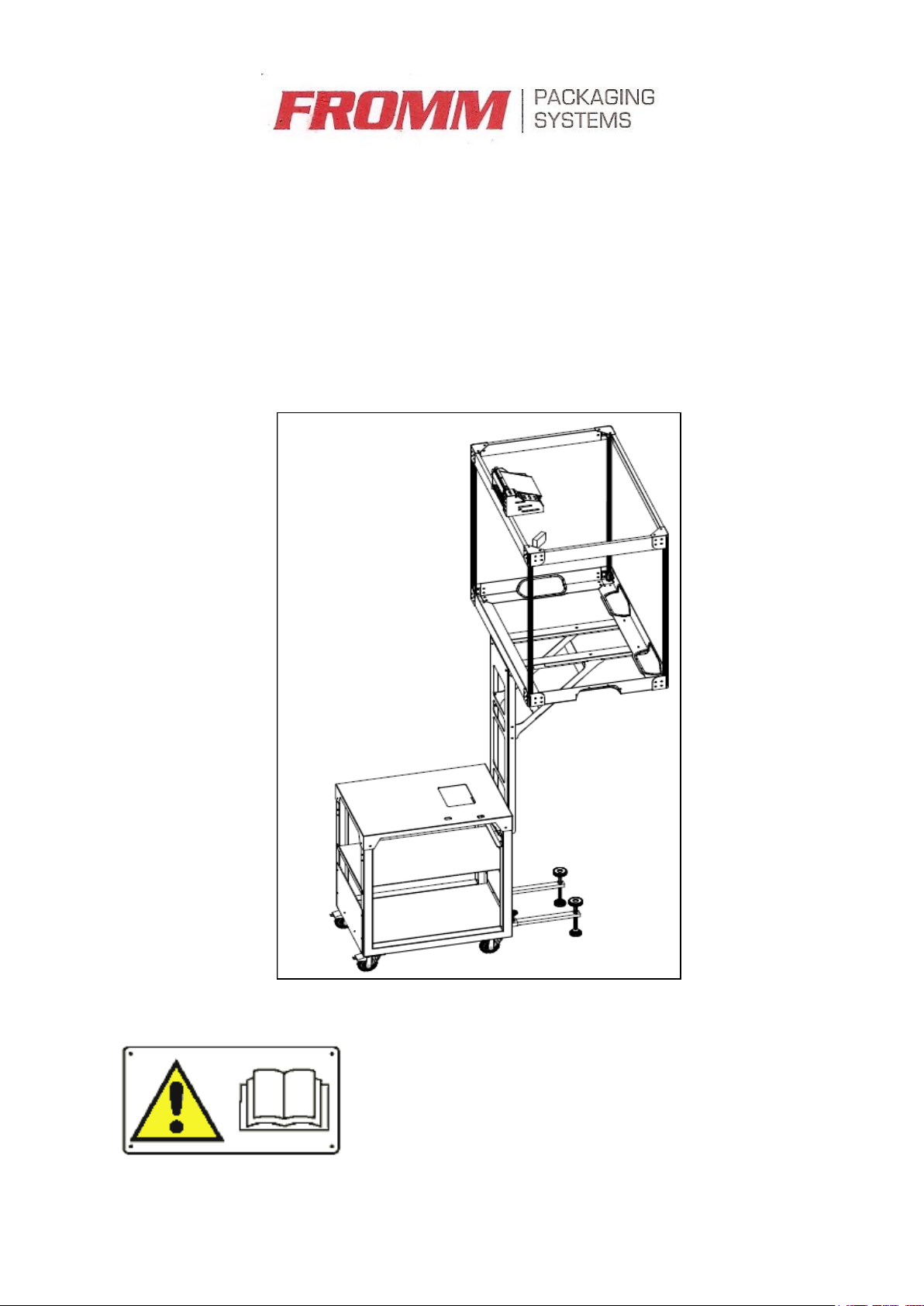

2INTRODUCTION

This document contains instructions on machine installation and startup.

Spare parts must be obtained directly from your authorized Dealer.

FROMM is always available to provide assistance to its Customers and

reiterates the fact that failure to follow the instructions provided in this

document will void the machine warranty.

In order to correctly use this machine, basic definitions for risk assessment and

safe design should be considered:

3GENERAL SAFETY INFORMATION

Do not attempt to assemble the machine without having

carefully read this Manual.

Users must always comply with the local health and safety

legislation that is applicable in the country in which the

machine is installed.

Failure to comply with the information provided in this

Manual will release CO.ME.SA.SRL from liability.