5

Status Provac 360 is the rst machine for professional

use from Status Innovations. It is intended for long-term

storage of foodstuffs in vacuum and for vacuum packing

of foods in bags or vacuum containers. It was developed

especially for professional kitchens, butcheries, chee-

series, and other production facilities, which store large

quantities of foods daily. It can also be used by those

who want only the best and have large quantities of

foods they want stored quickly and efciently.

This machine represents the new generation of Status

vacuum packing machines, designed to be even more

user-friendly. It is developed and produced by Status

d.o.o. Metlika, Slovenia.

It features unprecedented NEW FUNCTIONS:

• Status Smart Seal: A sealing process, which

ensures remarkably fast vacuum packing cycles

and what is more it is energy efcient.

• The machine automatically adjusts sealing time

according to the temperature of the sealing

mechanism (the longer the machine is active,

the less time is needed to complete the sealing

process).

• During the sealing process the machine is com-

pletely silent and energy-efcient. Since it has

two sealing bars Provac 360 does not need to

be preheated before operation. The double seal

acts as an additional safeguard when vacuum

packing moist and delicate foodstuffs in case

liquid would seep through the rst seal.

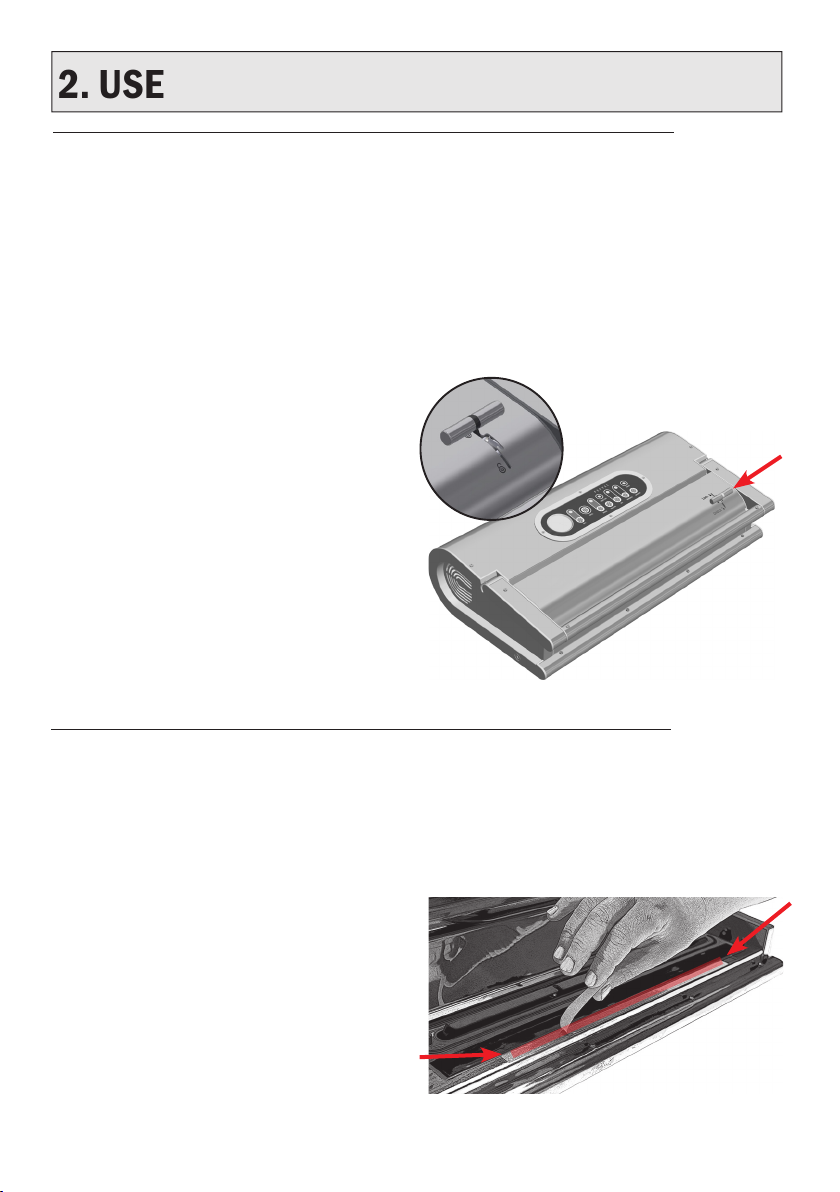

• Status Smart Open/Lock:

• The lid of the machine opens automatically in

the Auto mode.

• Exceptionally easy locking/unlocking due to the

readily accessible handle on the lid.

• A pivoted locking system enables the lock to be

operated quick and easy and does not require

great force. The construction is designed to lock

securely and without undue wear to the materi-

als, which ensures the longevity of the product.

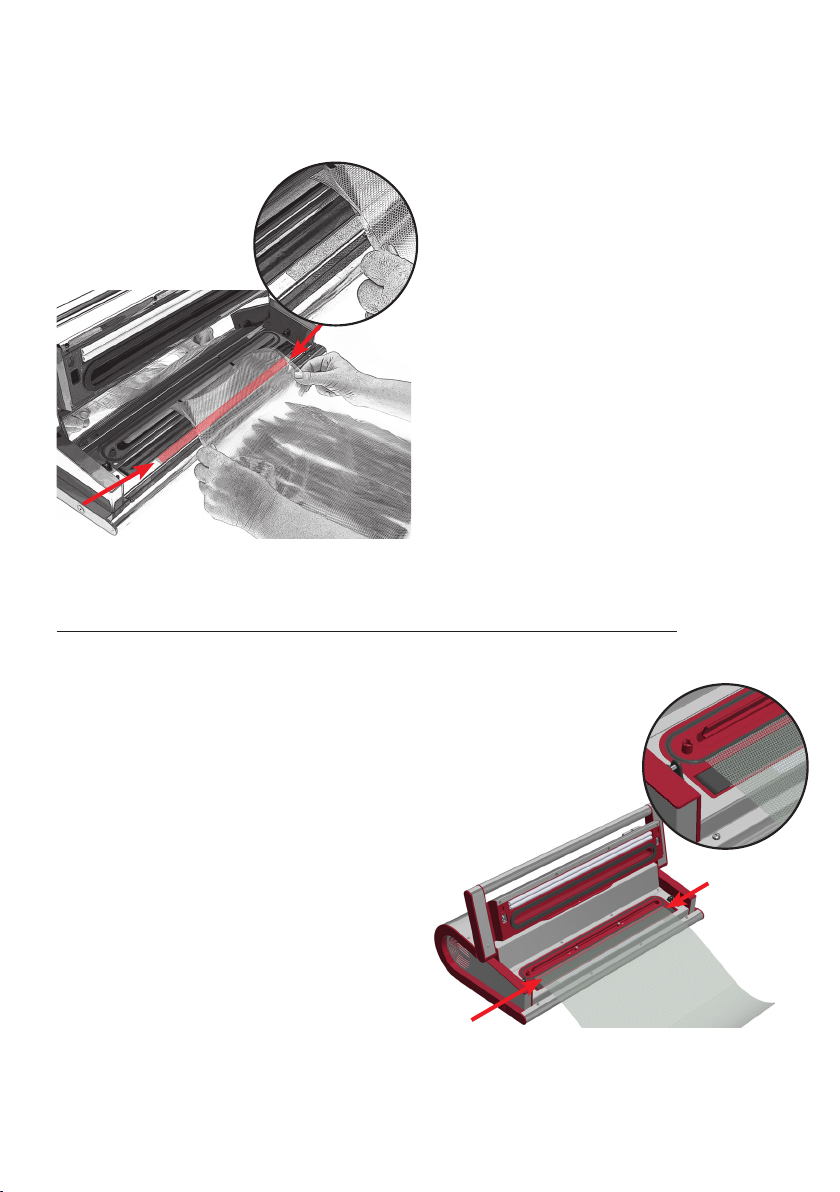

• Status Stiki: A reusable and easily detachable

double-sided adhesive tape for the easiest vacuum

packing in the world. Attach the adhesive tape to

the designated position, remove the top protective

layer and simply tape the bag to the Stiki adhesive

1.4. GENERAL INFORMATION

tape before vacuum packing. The bag is perfectly

straight and without creases, while the accuracy of

bag placement on the sealing strip ensures the most

economical use of the bag. The machine comes with

ve Status Stiki adhesive tapes, which allow for up to

1000 vacuum packing cycles.

Most signicant advantages of vacuum storage:

• Preserves vitamins, minerals, nutrients, and the

aroma of foodstuffs.

• Protects foodstuffs from the spread of mould and

bacteria.

• Prolongs the shelf life of foodstuffs.

• Prevents the unpleasant mixing of odours in

a refrigerator and freezer.

You can also prolong the freshness and shelf life of

foodstuffs by using Status vacuum containers, lids, a

canning jar sealer and a jug, which can all be vacuum

sealed with a manual or an electric vacuum pump. All

these products can also be vacuum sealed with Provac

360 which comes equipped with a special tube for this

type of vacuum packing.

We also have to mention that Status' Provac 360 helps

you save money, since you can buy in bulk, repackage

your purchase in portions and then vacuum package.

Food can be divided into smaller serving portions,

vacuum packaged and stored in the refrigerator for a

longer period of time.

The serial number is located on the technical label of

each individual machine.

Before rst use please read the user manual thoroug-

hly and follow the instructions.

Contact us if you have additional questions, opinions or

comments.

For more explicit directions visit our website

http://innovations.status.si/shop/vacuum-packing-

-machines. Use the same address to locate an online

version of this user manual.

The use of the machine is simple and efcient. You will

store food in an entirely natural and healthy way, the

food will remain fresh longer, and you will save time and

money.