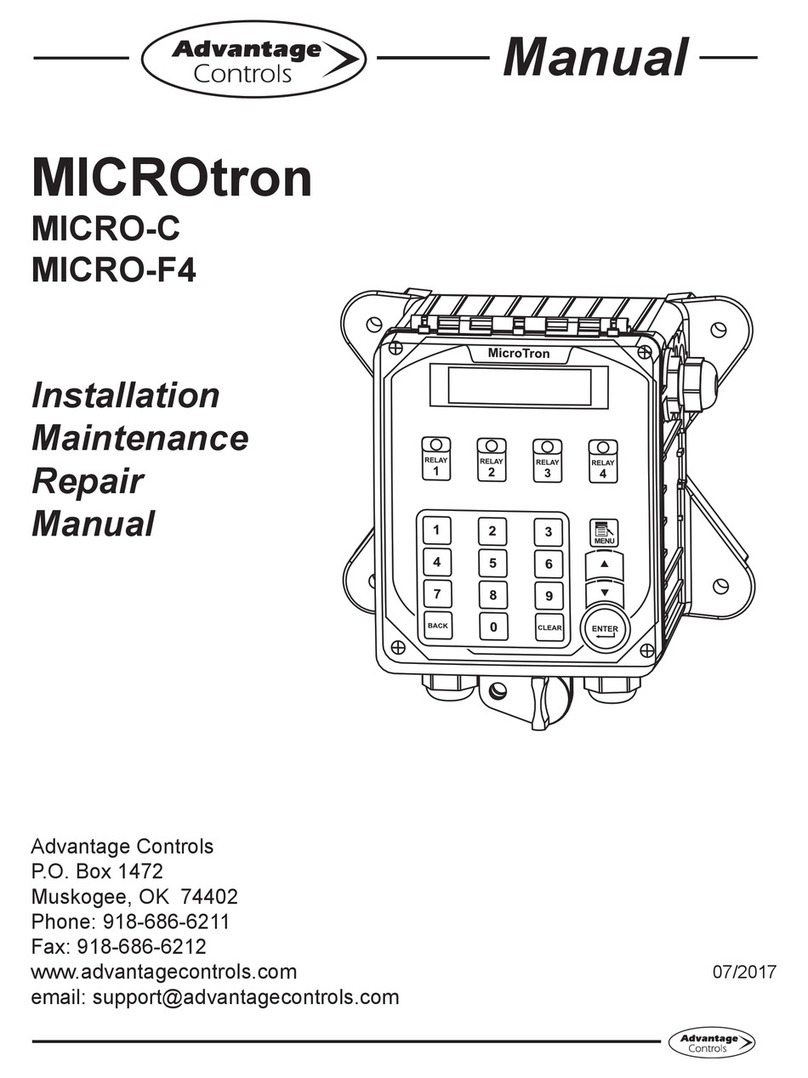

Advantage Controls MicroTron User manual

1

Manual

MicroTron

Tower Controller

Installation

Maintenance

Repair

Manual

Advantage Controls

4700 Harold Abitz Dr.

Muskogee, OK 74403

Phone: 918-686-6211

Fax: 888-686-6211

www.advantagecontrols.com

email: [email protected]

04/19

2

MicroTron Tower Controller

Instruction & Maintenance Manual

Table of Contents

Contents Page

I. Introduction................................................................................. 3

Model Numbering ....................................................................... 3

II. Description of Unit ...................................................................... 4

III. Installation .................................................................................. 5

Electrical Wiring.......................................................................... 5

Mounting Instructions ................................................................. 5

Conduit Layout for LCD Display ................................................. 6

Typical Installation ...................................................................... 6

Electrode Installation .................................................................. 7

IV. Front Panel Description.............................................................. 8

V. System Operation Overview....................................................... 9

A. Description of Set Up Menu Screens.................................... 9

1. Calibration...................................................................... 10

2. Bleed Set........................................................................ 11

3. pH Feed Set................................................................... 12

4. ORP Feed Set................................................................ 13

5. Chem Feed Set.............................................................. 14

6. Biocide Set..................................................................... 15

7. Clock Set........................................................................ 16

8. System Menu Set........................................................... 17

9. Diagnostics Menu........................................................... 19

B. Run Menu............................................................................ 20

VI. Maintenance............................................................................. 21

VII. Troubleshooting........................................................................ 21

VIII. Warranty & 30 Day Billing Memo Policy ................................... 23

Instructions herein apply to all MicroTron tower controllers.

Additional options described in this manual may or may

not be present on your unit. Refer to Model Numbering on Page 3.

3

I. Introduction

MicroTron controllers are microprocessor based menu driven units for control of recirculating and other

water applications. All settings are entered into the controller through a simple front panel keypad which

includes relay test keys.

Model Numbering

MicroTron controllers have several base functions and optional features available. Your unit may be supplied

with one or more of the options that are described in this manual. To determine what features apply to your

unit, check the model number label located on the controller enclosure.

Base Functions

All model numbers can be broken down as follows

and will start with an Mor L.

MMicroTron with a VFD display

LMicroTron with an LCD display

CConductivity Control

C-0 Conductivity Monitor only

C-2 Adds make-up conductivity function

FSingle programmable feed timer

F-2 Dual feed timers

F-3 Triple feed timers

F-4 Quadruple feed timers

F-5 Five feed timers

BSingle 28 day timer

B-2 Dual 28 day timers

B-3 Triple 28 day timers

B-4 Quadruple 28 day timers

PpH control

P-0 pH monitor only

P-2 pH control with dual set points

RORP control

Optional Features

This list represents our most popular options.

AConduit connections

A-6 On/Opowerswitch

A-7 Lower enclosure

C-1 0-5V non-isolated output

C-4 Single 4-20mA non-isolated output

C-6 Single isolated 4-20mA output

D220 V service (conduit only)

E Mountedowswitchassembly

MAlarm relay options

M-1S Sonic alarm buzzer with silence switch

NNon standard conductivity scales

QAlternate electrodes

RMolex connector on conductivity electrode

V Digitalinputforbleed-owatermeter

WPower relay 1.5 HP max, 25 amps

XTank low level alarms

Y Bleedowalarm(requiresowswitch)

Z-6 One water meter input for each chemical

feed timer

Z-11 Lockout chem feed with low conductivity alarm

9 Paddlewheelowmeterinput

Note:Thelistoffunctionsandoptionsrepresentspastandcurrentoerings.

Some of these may no longer be available on new units, but are listed for reference.

4

II. Description

Control Functions

Each of the control functions is based on an analog input from a probe and will include user settable relay

control settings along with a High and Low Alarm setting and Limit Timer. Each control function will include

a control relay output. When the reading reaches the Set Point the control relay is activated until the

readingchangesbytheDierentialamount.

1. Conductivity - The conductivity function of the controller is designed to monitor and control

Total Dissolved Solids (TDS) in a recirculating system like a cooling tower in terms of electrical

conductivity measured in MicroSiemens/cm. This control function is also referred to as bleed. Units

with conductivity and the make-up conductivity function can control the TDS of the tower system

toacyclesofconcentrationbycalculatingthedierencebetweentheincomingmake-upwater’s

conductivityandthesystem’sconductivity

2. pH - The pH function monitors and controls pH on a scale of 0-14 pH units.

3. ORP - The ORP function monitors and controls ORP on a scale of +/- 999 mV.

Chemical Feed Timers

Selectable Chemical feed timers (base function F) are designed to automate the addition of various

chemicals by activating a relay output. Multiple timers can be supplied depending upon the model number

and each timer will include a relay output. All timers can be programmed to be one of the following types.

1. Pulse Time - This timer accepts dry contact pulses from a make-up water meter (supplied

separately). It can accumulate 1-99 pulses to activate the timer to run from 0-99 minutes in minutes

and seconds.

2. Feed with Bleed - This timer activates the relay output simultaneously with the bleed. The timer

can limit the amount of time the relay output will be on during the bleed cycle, thereby preventing

chemical overfeed.

3. Feed after Bleed-Thistimeractivatestherelayoutputbasedonauserdenedpercentageof

thebleedotime.Therelayisactivatedafterableedcycleandrunsforthesetpercentageofthat

bleed cycle. A limit time can also be set for the maximum amount of time the timer can run for one

cycle.

4. Percentage - The relay is on for a percentage of a continuously repeating cycle time. The percentage

timer can be set from 1 to 99% and the cycle time can be set from 1 second to 99 minutes and 59

seconds.

28-Day Feed Timers

28-day feed timers, typically used for biocide feed are based on a 28 day cycle with two independent

programmable feed cycles allowing for feed on selectable days and weeks. The biocide timers also

include prebleed and bleed lockout settings. Multiple timers can be supplied depending upon the model

number and each timer will include a relay output.

5

III. Installation

Electrical Wiring

The standard MicroTron Tower controller has an internal regulated power supply that will operate in the range

of approximately 100 to 240 VAC on the incoming wiring. Output relay(s) are protected with a replaceable

fuse.Eachrelay’soutputvoltagewillequalincominglinevoltage.

Prewired units are supplied with a 16 AWG cable with 3-wire grounded USA 115 volt plug for incoming power

and 18 AWG 3-wire grounded U.S.A. 120 volt receptacle cords for all control relay outputs.

Conduit units are supplied with connectors located in the lower section of the controller. Remove the screws

of the lower panel for access and to view wiring diagram.

NOTE: Liquid tight ttings and labeled signal lead cables are provided for all signal (low voltage)

connections, such as water meter, low drum level, ow switch and 4-20mA outputs, for both pre-wired

and conduit units.

Mounting Instructions

Select a mounting location that provides the operator easy access to the unit and a clear view of the controls

through the cover of the controller. The location should be convenient to grounded electrical connections, the

requiredsamplelineplumbing,andinstalledonastableverticalsurface.

CAUTION

1. There are live circuits inside the controller even when the power switch on the front panel is in

the OFF position. Never open the front panel without rst disconnecting power from the outlet.

Prewired controllers are supplied with an 8 foot, 18 AWG power cord with USA style plug. A #1

Phillips driver is required to open the front panel.

2. Low voltage signal wires (probes, ow switch, water meter, etc.) should never be run

in conduit with high voltage (like 115VAC) wires.

3. Never attempt to land connections to the controller without rst disconnecting power from the outlet.

4. Do not block access to disconnect power during mounting and installation.

5. The controller should be connected to its own isolated circuit breaker, and for best

results, the ground should be a true earth ground, not shared. Any attempt to bypass the grounding

will compromise the safety of users and property.

6. The electrical installation of the controller must be performed by trained personnel only and

conform to all applicable National, State and Local codes.

7. Operation of this product in a manner not specied by Advantage Controls may result in damage

to equipment or persons.

8. Avoid mounting in locations that expose the controller to direct sunlight, vapors, vibration,

liquid spills or extreme temperatures; less than 0°F (-17.8°C) or greater than 120°F (50°C).

EMI(electromagnetic interference) from radio transmissions and electric motors can also cause

damage or interference and should be avoided.

! !

6

Conduit Layout for LCD Display

Logic Board

Serial Line

Connection

R

B

R

B

R

B

R

B

Level Wand

Level 2

Level 3

Level 4

Water

Meter

Input

Make/up

Switch

Make/up

Cal.

Make/up

Cond.

Probe

B

R

B

R

Pressure

Sensor #1

Pressure

Sensor #2

R

B

ISO

4-20

Out

To 4-20

Board

LCD

Contrast

TP-8

TP-6

TP-7

TP-10

-12

+5

+5

Gnd

Gnd

+12

TP-3

GND

TP-4

TP-2

TP-5

TP-1

-5 +5

-12 +12

R

B

R

B

R

B

R

B

R

B

Pulse 1

Pulse 2

Pulse 3

Pulse 4

Bleed Meter

Flow

R +12 VDC

B GND

B

R

W

G

B

R

W

G

Eprom

ADJ.

TP6

Cond. Switch

OFF / ON

Cond.

Cal.

Conductivity

Probe

OFF

ORP

Test

OFF

ORP

Test

10 9

21

Ribbon

Cable for

Relays

SIGNAL

GROUND

+ vdc for opt.9

Relay / Power Board (Rev. D)

Ribbon Cable

2

1

10

9

POWER INPUT

POWER SUPPLY

Relay 1 Relay 2 Relay 3 Relay 4 Relay 5

5A (R1)

5A (R3)

5A (R2) 5A (R4)

5A (R5)

NEU GND

N.O. N.C.

NEU GND

N.O. N.C.

NEU GND

N.O. N.C.

NEU GND

N.O. N.C. NEU GND

N.O. N.C.

H N G

Rev. D

Relay / Power Board (Rev. B)

Ribbon Cable

2

1

10

9

5A

POWER INPUT

H N G

Relay 5

5A

5A

Relay 3

5A

Relay 2

NET

GND

N.O.

N.C.

5A

Relay 1 Relay 4

POWER SUPPLY

NET

GND

N.O.

N.C.

NET

GND

N.O.

N.C.

NET

GND

N.O.

N.C.

NET

GND

N.O.

N.C.

Rev B

Relay / Power Board (Rev. C)

Relay 5

Relay 3Relay 2Relay 1 Relay 4

POWER SUPPLY

Relay / Power Card (REV D)

Green (-12)

White (+5)

Red (+12)

Black (Gnd)

FUSE

FUSE

FUSE

FUSE

FUSE

1

Relay 1

2

Relay 2

4

Relay 4

35

N.O N.C NET GRD

N.O N.C NET GRD

N.O N.C NET GRD N.O N.C NET GRD

N.O N.C NET GRD

H N G

POWER INPUT

Ribbon Cable

1

2

9

10

Typical Installation

BLOWDOWN

COOLING TOWER

CIRCULATION PUMP CHILLER

MAKE-UP

WATER METER

BLEED VALVE

7

Electrode Installation

MicroTrontowercontrollersmaycomeconguredforvariousrecirculatingwatersystems.Listedbelow

areinstructionsfortypicalcoolingtowerinstallations.Yourspecicinstallationrequirementsmaydierbut

should conform to these instructions as much as possible for proper operation.

Thestandardprobe(s)and/orowassemblyforcoolingtowerinstallationsisconstructedofschedule

80PVCandsuppliedwith¾”slipttingsforinstallingintoasampleline.Toinsureproperoperationthe

samplelinemusthaveaowrateof3-10gpm.Inletpressuremustbehigherthanoutletpressureinorder

forwatertoowpasttheelectrode(s)attherequiredrate.Theprobesaretemperaturecompensatedfor

increased accuracy.

NOTES:

1. Install an isolation valve on either side of the ow assembly so electrodes can be

easily isolated for removal and cleaning.

2. A line strainer is recommended upstream from the probes to protect against fouling

and damage.

3. Mount pH electrodes vertically.

4. Units with a ow switch require the needed ow rate to operate the relay outputs.

5. Tap points for sample line should not be at the top or bottom of the supply piping to

reduce air or debris introduction to sample line.

WARNINGS:

1. Electrodes are O-ring sealed, which if damaged will cause a leak.

2. Do not allow pH sensor tips to dry out, damage will occur.

3. Do not exceed a water temperature range of 32°F to 140°F.

4. Do not exceed a maximum pressure of 150 psi.

FS-OC FS-F2

E-30

FS-FC

FS-SP

-or-

PE-21

OE-21

PE-NUT

pH Probe

ORP Probe

FS-SPRING

If ordered

OR

FS-T

TFS-OC

TFS-C

Conductivity

Probe

FS-B1-SP

MW-T-3

MW-T-3-2

MW-T-3-3

E-30

E-4A

SampleValve

E-30-PH E-30-PH

UNION-3/4T

2C0A-150

8

IV. Front Panel Description

READ: 1x16 (1/4”) Alpha Numeric Display.

CONTROL: Relay 1, Relay 2, Relay 3, Relay 4 - HOA switches for control relays.

SET UP/RUN key - System initializes into RUN mode. Press this switch to toggle the controller

from SET UP mode to RUN mode.

UP/DOWN arrows - Used to change the display from one line to the next. All menus are circular,

so when all items in a menu have been displayed, the display will return to the

originally displayed item.

ENTER key - Used to access a menu and to log a changed value into the program.

CLEAR key - Used to clear numerical values from items being changed in the SET UP

mode.

DECIMAL key - Used at certain places to change a function or displayed items. For example,

when temperature is being displayed, pressing the DECIMAL key will change

the reading from Fahrenheit to Celsius or visa versa.

NUMERICAL keys - Used to enter new values in the SET UP mode.

Standard Tower Probes

Conductivity...................................................................................................................................E-4A

pH..................................................................................................................................................PE-2

ORP.............................................................................................................................................. OE-2

ENTER

CLEAR

•

1

SET UP

RUN

9

V. System Operation Overview

MicroTron controllers have two modes of operation, RUN and SET UP. Both the RUN and SET UP menus

are circular. Pressing the DOWN key in either menu will display the next line of information on the display.

After the last item in a menu has been displayed, pressing the DOWN key will return the display to the top

line of that menu.

RUN MODE - This mode is for normal operation. The control relays will only be automatically activated

in this mode. In the RUN mode the display will read system values. If an alarm is present

thedisplayasheswiththealarmstatus.

The RUN menu will display values such as conductivity, pH, day, time, date and other

values depending upon the features present on the unit. The unit will automatically return

to the RUN mode if no keys are pressed for three minutes.

SET UP MODE - This mode is used to make adjustments to settings and readings on the controller. To

access the SET UP mode from the RUN screen, press the SETUP/RUN key. Use the

up or down arrow to scroll through the various SET UP menus. When you want to enter

aspecicSETUPmenu,presstheENTERkey.OnceyouhaveenteredaSETUPsub

menuyouwillbeabletostepthroughthatmenu’soptionswiththedownarrowkey.

Relays may be forced on while in the SET UP mode. Press the desired relay test key to

forceiton.Pressitasecondtimetoturnito.OncetheunitreturnstotheRUNmode,

relays will activate automatically.

Therelay4testkeywillactivaterelay4ontherstpress,thenwillactivaterelay5on

thesecondandwillturnboth4and5oonthethird.

A. Description of SET UP Menu Screens

The SET UP menu is the main menu circle of set up sub-menus used to customize your unit to the particular

parameters needed for your installation. Listed on the following pages is a description and menu map of each

SET UP menu.

NOTES:

1. Your unit may not have all of the SET UP menus listed depending upon your model number.

2. After you press ENTER or CLEAR to change a numerical value in the SET UP menu, use the

numberkeystodenethenewvalue.PressENTERagaintoenterthenewvalue.

3. When entering new numeric values, all available digits (characters) must be entered. The number

of available digits depends upon the scale of operation. Position of cursor indicates number of

digits to be entered.

For example, when entering a run time value for a timer in the minute and seconds scale (10:30

wouldequal10minutesandthirtyseconds).Youwouldneedtokeyinanumberof0030tomake

it 0 (zero) minutes and 30 seconds.

10

1. CALIBRATION

All MicroTron controllers are factory calibrated for

temperature, conductivity, pH and/or ORP (if present).

These values should be veried for accuracy, and

adjusted as per the instructions listed below and to the

side.

Calibrating the temperature reading, press SET UP/

RUN button. The “CALIBRATION” screen will appear.

Press ENTER and the screen will read “CALIBRATE

F”. Press ENTER to log in the new reading. To display

the reading in degrees Celsius, press the decimal key.

High Temp Alarm Set - If this is exceeded the Alarm

will activate, set to 0 to disable.

Calibrating the Conductivity with the probe in a

known solution, select “CALIBRATE uS” from the

“CALIBRATION” menu. Press CLEAR, then key in the

corrected conductivity value. Press ENTER to log in

that reading.

Calibrating the pH with the probe in solution on line.

Select “CALIBRATE PH” from the “CALIBRATION”

menu. Press CLEAR, then key in the corrected pH

value. Press ENTER to log in that reading.

Calibrating the ORP with the probe in solution on line.

Select “CALIBRATE ORP” from the “CALIBRATION”

menu. Press CLEAR, then key in the corrected ORP

value. Press ENTER to log in that reading.

The limits on this factor are from 50% to 200% and any

entry which would lead to a factor outside this range

will cause it to default back to the previous value.

NOTES:

1. After entering a new numerical value hit the

ENTER key to accept value and advance.

2. For severe calibration problems, see Reset

Zero and Recentering pH on page 22 & 23.

2. BLEED SET

-- CALIBRATION --

CALIBRATE xxxoF

To change temperature

To accept value keyed in

using number keys

HIGH TEMP xxxoF

To change value

To accept value keyed in

using number keys

CALIBRATE XXXXXuS

To change conductivity reading

To accept value keyed in

using number keys.

CALIBRATE XX.X.pH

To change pH reading

To accept value keyed in

using number keys.

CALIBRATE XXX ORP

To change ORP reading

To accept value keyed in

using number keys.

Returns to CALIBRATION screen

ENTER

CLEAR

ENTER

ENTER

CLEAR

ENTER

CLEAR

ENTER

CLEAR

ENTER

CLEAR

11

This menu is used to set bleed control parameters

including set point, dierential, high and low alarms

plus a feed limit timer.

BleedTrip - A reading above this value will activate the

blowdown relay until the reading falls by the amount of

thedierentialbelowthetrippoint.

Dierential - With a rising trip point the bleed relay

comes on if conductivity exceeds the trip point and

goes o when it falls below the trip point minus the

dierentialvalue.

The dierential may be made negative by using the

DECIMAL key during edit. If negative, the Trip Point

changes from rising to falling.

High Alarm Setting - Setting for a high conductivity

alarm condition.

Low Alarm Setting - Setting for a low conductivity

alarm condition.

Bleed Limit Timer - The bleed limit timer is set in

hours and minutes. If the unit bleeds longer than the

limit timer is set for an alarm is given. Maximum value

is 9 hours and 59 minutes. A setting of zero disables

the timer.

3. PH FEED SET

-- CALIBRATION --

BLEED TRIP XXXX

To change bleed trip point

To accept value keyed in

using number keys

DIFFERENTIAL XXXX

Tochangedierential

To accept value keyed in

using number keys

HIGH ALARM XXXX

To change high alarm setting

To accept value keyed in

using number keys.

LOW ALARM XXXX

To change high alarm setting

To accept value keyed in

using number keys.

BLEED LIMIT H.MM

To change bleed limit time

To accept value keyed in

using number keys.

Returns to BLEED SET screen

ENTER

CLEAR

ENTER

ENTER

CLEAR

ENTER

CLEAR

ENTER

CLEAR

ENTER

CLEAR

12

This menu is used to set pH control parameters

including set point, dierential, high and low alarms

plus a feed limit timer. (This menu choice will be

present only if you have the pH control option, see

model numbering on page 3.)

pH Trip - The pH reading value that will activate the

pH relay.

pH Di - Normally a rising trip point, the pH relay

comes on if pH exceeds the trip point and goes o

whenitfallsbelowthetrippointminusthedierential.

The dierential may be made negative by pressing

theDECIMALkeywhenchangingdierentialsetting.

When the dierential is negative, the Trip Point

changes from rising to falling.

High Alarm Setting - Setting for a high pH alarm

condition.

Low Alarm Setting - Setting for a low pH alarm

condition.

pH Limit Timer - The pH limit timer is set in hours and

minutes. If the unit calls for feed longer than the limit

timer is set for, an alarm is given and the pH feed is

stopped. Maximum value is 9 hours and 59 minutes. A

setting of zero disables the timer.

After entering a new numerical value hit the ENTER

key to accept value and advance.

NOTES:

If a unit has dual pH trip points, there will be

a group of settings for “PH A” followed by the

settings for “PH B”.

4. ORP FEED SET

-- PH FEED SET --

PH TRIP XXX

To change pH trip point

To accept value keyed in

using number keys

PH DIFF XXX

TochangepHdierential

To accept value keyed in

using number keys

HIGH ALARM XX

To change high alarm setting

To accept value keyed in

using number keys.

LOW ALARM XX

To change low alarm setting

To accept value keyed in

using number keys.

FEED LIMIT H.MM

To change feed limit timer setting

To accept value keyed in

using number keys.

Returns to PH FEED SET screen

ENTER

CLEAR

ENTER

ENTER

CLEAR

ENTER

CLEAR

ENTER

CLEAR

ENTER

CLEAR

13

This menu is used to set ORP control parameters

including set point, dierential, high and low alarms

plus a feed limit timer. (This menu choice will be

present only if you have the ORP control option, see

model numbering on page 3.)

ORP Trip - The ORP reading value that will activate

the ORP relay

ORP Di - Normally a falling trip point, the ORP relay

comesonifORPfallsbelowthetrippointandgoeso

whenitrisesabovethetrippointplusthedierential.

The dierential may be made positive by pressing

theDECIMALkeywhenchangingdierentialsetting.

Whenthedierentialispositive,theTripPointchanges

from falling to rising.

High Alarm Setting - Setting for a high ORP alarm

condition.

Low Alarm Setting - Setting for a low ORP alarm

condition.

ORP Limit Timer - The ORP limit timer is set in hours

and minutes. If the unit calls for feed longer than the

limit timer is set for, an alarm is given and the ORP

feed is stopped. Maximum value is 9 hours and 59

minutes. A setting of zero disables the timer.

After entering a new numerical value hit the ENTER

key to accept value and advance.

5. CHEM FEED SET

-- ORP FEED SET --

ORP TRIP XXX

To change trip point

To accept value keyed in

using number keys

ORP DIFF XXX

Tochangedierential

To accept value keyed in

using number keys

HIGH ALARM XX

To change high alarm setting

To accept value keyed in

using number keys.

LOW ALARM XX

To change low alarm setting

To accept value keyed in

using number keys.

FEED LIMIT H.MM

To set feed limit time

To accept value keyed in

using number keys.

Returns to ORP FEED SET screen

ENTER

CLEAR

ENTER

ENTER

CLEAR

ENTER

CLEAR

ENTER

CLEAR

ENTER

CLEAR

14

Units with selectable feed timer(s) will have this SET

UP menu for selecting the chemical feed method

and setting the feed time. A selectable feed timer

can be programmed to be one of the following:

1. PULSE TIME - A timer activated by dry

contacts from a contacting head water meter

and includes an accumulator for counting the

number of pulse (contacts) before starting the

timer.

2. WITH BLEED - A feed limit timer that runs

during a bleed cycle. The chemical feed will run

for as long as the bleed occurs or until the limit

time is reached.

3. POST BLEED - This timer counts how long

a bleed cycle lasts then runs the chemical

feedafterthecycleisoverforauserdened

percentage of the bleed time. A limit timer

prevents over feeding.

4. PERCENTAGE - A continuously repeating

timer where the cycle timer can be programmed

along with the percentage of ON time for the

cycle.

6. BIOCIDE SET

-- CHEM FEED SET --

Shows timer currently selected

Tochangetoadierenttimer

To cycle through timer options

CHEM A PULSE TIME

CHEM A WITH BLEED

CHEM A POST BLEED

CHEM A PERCENTAGE

To Select timer

To bypass the feed method selection

-- CHEM A POST BLEED --

CHEM A PERCENT XX

To change percentage

CHEM A TIMER XX Min.

To change limit time

Returns to CHEM FEED SET

-- CHEM A PERCENTAGE --

CHEM PERCENT XX

To change percentage

CHEM A CYCLE XX.XX

To change cycle time

Returns to CHEM FEED SET

ENTER

ENTER

ENTER

-- CHEM A PULSE TIME --

CHEM PULSES XX

To change # of pulses

CHEM A TIMER XX.XX Min.Sec

To change Chem A timer

Returns to CHEM FEED SET

-- CHEM A WITH BLEED --

CHEM A LIMIT XX.XX Min.Sec

To change limit

Returns to CHEM FEED SET

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

15

Units with a biocide timer will have this SET UP menu

for setting biocide feed times. Biocide Set Menu

consists of two weekdays, week and start times, one

feed length time and an overall prebleed and lockout

setting for each biocide.

BIO __ (A1,A2,B1,B2...) WEEKDAY - Select from

Sunday through Saturday, or TuesThrSat, MonWedFri,

Every Other day, Every Day or No Day. A setting of No

Day disables timer.

BIO__(A1,A2,B1,B2 ...) WEEK - Select week (1-4),

Even Weeks, Odd Weeks, or Every Week. A setting of

No Week disables timer.

BIO__(A1,A2,B1,B2 ...) MONTH - Select month

(1-12), Even Month, Odd Month, or Every Month.

A setting of No Month disables timer.

BIO_(A,B,C...)TIME HH.MM - Start time based on 24

hour clock, in hours and minutes.

BIO_(A,B,C...) LENGTH H.MM - Feed time in hours

and minutes can be set up to 9 hours and 59 minutes,

0 (zero) disables both start times for that biocide.

BIO_ (A,B,C...) PREBLEED H.MM - Prebleed and

lockout settings are in hours and minutes, with a

maximum of 9 hours and 59 minutes, 0 (zero) disables

timer. When the clock reaches a start time for any of

the four timers, the Prebleed is begun.

BIO_(A,B,C...) LOCKOUT H.MM - The lockout timer

is a timer that starts after the biocide feed time is

nished.Thetimercanbesetforatimeupto9hours

and 59 minutes to lock out the bleed.

7. CLOCK SET

-- BIOCIDE SET --

Shows BIO A timer 1 activation day

To change day of the week

To cycle through day options

SUN,MON,TUES,WED,THUR,FRI,SAT,

ALTERNATE ...

To select day

Shows BIO A timer 1 activation week

To change week

To cycle through week options

press ENTER to set week

Shows BIO A timer 1 activation month

To change month

To cycle through month options

press ENTER to set month

Shows BIO A Timer 1 start time of day

To change Time of Day

To enter time keyed in using

number keys

Menu repeats for BIO A Timer 2

BIO A LENGTH 0.00 (H.MM)

To change length

To accept value keyed in

using number keys.

BIO A PREBLEED 0.00 (H.MM)

To change length

To enter time keyed in

using number keys.

Continued..

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

CLEAR

ENTER

CLEAR

ENTER

CLEAR

BIO A LOCKOUT 0.00 (H.MM)

To change length

To enter time keyed in

using number keys.

Program repeats for addional biocide

timers if ordered (B, C, and D)

ENTER

CLEAR

16

The CLOCK SET menu is for adjusting the time, date

and day of the week.

After entering a new value, hit the ENTER key to

accept the value and advance.

The clock time is based on a 24 hour clock. So, a time

of 1 pm would be shown as 13.00.00.

NOTES:

If unit doesn’t have a biocide timer, there

will not be a SET WEEK selection.

8. SYSTEM SET MENU

-- CLOCK SET --

SET TIME XX.XX.XX (hh.mm.ss)

To change clock setting

To accept value keyed in

using number keys

SET DATE XX.XX.XX

To change date

To accept value keyed in

using number keys

SET WEEK X

To change week

To cycle through week options.

To set week

Returns to CLOCK SET

ENTER

CLEAR

ENTER

ENTER

CLEAR

ENTER

ENTER

17

Thismenuisusedtocongurethecontrollertospecic

operational needs. All of the items in this menu may

not apply depending on the controller model but will

always be present.

NOTE: Do not use this menu to make calibration

adjustments. Use the Calibration screen.

PASSWORD - If a value of 0000 is entered, a

passwordisnotrequired.Ifapasswordis

entered, it must be used to operate the controller.

Iftherstdigitiszero,relaysmaybeactivated

without a password.

RESET WATER METER COUNT - Does not

apply unless the unit has selectable feed timer.

DRY CONTACT HEAD - Select a contacting head

watermeterorahalleectpaddlewheelmeter.

Anytime this setting is changed the GAL/PULSE

value will need to be re-entered.

GAL/PULSE - If a feed timer is using a contacting

head water meter this tracks make-up volume by

enteringthenumberofgallonsacontactequals.

Use•keytochangetopulse/galforowmeter.

STRAIGHT/PROPORTIONAL OUTPUTS - A

straight output setting means the optional 4-20

output span will be the same as the full scale.

The proportional setting allows the span of the

4-20 mA output to be selected by the user based

onthesetpointanddierential.

LOW DRUM NO PUMP/PUMP LOW DRUMS - If

unit has low level alarms, allows the associated

feedtimertobeforcedowhendrumislow.

COMM Setup:

BAUD RATE - For units ordered with the serial

line or modem option.

ALARM CALL - For units with modem.

FLOW WHEN CLOSED -Forowswitches.

-- SYSTEM SET --

PASSWORD XXXX

Numeric keys to set

password

RESET METER

Count zeroed

DRY CONTACT HEAD

To change to HALL EFFECT

ENGLISH UNITS

METRIC UNITS

GAL/PULSE

Numeric keys to change

gal/pulse

BLEED/PULSE

Numeric keys to change

gal/pulse for bleed

STRAIGHT OUTPUTS

To change to PROPORTIONAL

OUT

PUMP LOW DRUMS

To change LOW DRUM/ NO

PUMP

BAUD RATE 1200

To change baud rate

System Set continued on next page.

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

18

SYSTEM SET (continued)

FLOW ALARM - With FLOW ALARM ON when

thesystemlosesow,analarmsignalcanbesent.

FLOW ALARM OFF means that no alarm signal is

sentintheeventoflossofsystemow.

CONCURRENT - Only applies if there are two or

more feed timers. This allows all feed timers to

become active simultaneously together.

SEQUENTIAL - Allows the feed timer to become

active in a chronological order based on settings.

ZERO CONDUCTIVITY - This is normally not

required, and is not recommended to use this

function unless instructed to do so by the factory.

NO BIOS WITHOUT FLOW - Allows the biocide

timer(s)torunonlywithaowconditionortoignore

theowandalwaysrunevenwithoutow.

FEED OK WHEN BIO - The chemical feed timer

can be prevented from activating during a biocide

timer run time.

NO BLEED ALARM-Withtheoptionalbleedow

alarm, the unit can produce an alarm if it is not

sensingowinthebleedlinewhenbleeding.

FEED OK IF BLEED - Lets the unit feed chemical

only when not bleeding or at anytime it is bleeding

if called for.

9. DIAGNOSTICS MENU

FLOW WHEN CLOSED

Flow When Open

FLOW ALARM ON

FlowAlarmO

FEED SEQUENTIAL

Feeds Concurrent

ZERO CONDUCTIVITY

Back to CALIBRATION

NO BIOS W/O FLOW

Bios With Flow

FEED OK WHEN BIO

No Feed When Bio

NO BLEED ALARM

Bleed Alarm

FEED OK IF BLEED

NO FEED IF BLEED

Return to SYSTEM SET

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

19

This menu is used to select, enter and test the

following items.

MODEL NUMBER - Read only screen.

SOFTWARE VERSION NUMBER - Read only

screen. Please have this number should you need to

contact customer service.

Have both available for service

TEST DISPLAY - Press ENTER and all pixels will

ash.Makeavisualchecktoseethatallpixelsare

lit.

TEST KEYPAD - Press ENTER, then press each

individual key to test its function. NOTE: Pressing the

SET UP/RUN key returns display to the main menu.

Pressing ENTER again returns to TEST KEYPAD.

RESET CALIBRATE - Resets ALL calibration data

to factory default calibration.

LEVELS INACTIVE - Press ENTER to select

between having level alarms active or inactive.

TEMP A/D - Shows the raw analog to digital value

for the temperature reading.

COND A/D - Shows the raw analog to digital value

for the conductivity reading.

CAL FACTOR - Shows internal calibration varible.

(slope of conductivity line) Default = 1000

ZERO FACTOR - Similar to calibration factor.

(zero point of conductivity line) Default = 0

These 4 screens aid in troubleshooting, please

havethisinformationavailableifyourequireservice

concerning conductivity readings.

B. Run Menu

-- SYSTEM SET --

MODEL # LCFB-2

FIRMWARE V.(n)

TEST DISPLAY

Displaywillash(allspaces

should light) press ENTER

againtonishtest

TEST KEY PAD

Key on keypad pressed,

corresponding number appears

ondisplay,ENTERtoquit

RESET CALIBRATE

If pressed resets calibrations to

factory defaults

LEVELS INACTIVE

Press ENTER to change

to ACTIVE

TEMP A / D

CONDUCTIVITY A / D

CAL FACTOR

ZERO FACTOR

Returns to DIAGNOSTICS

ENTER

ENTER

ENTER

ENTER

20

During normal operations the controller will be in the RUN mode where current values are displayed. If left in

the SET UP mode the display will revert to the RUN mode screen if no keys are touched for 3 minutes. If an

alarmispresentitwillbeashedonthescreenintheRUNmode.

While in the RUN mode if you hit the down arrow the following items may be shown:

COND Current conductivity value.

PH Current pH value.

ORP Current ORP value.

TEMP Current water temperature.

DAY-TIME Current day of the week and time.

DATE Current date.

BLEED TIME Ifbleeding,howlongithasbeenbleedingo.

CHEM (A) If a chemical feed relay is on, how long it has been on.

GALLONS If a water meter is being use, total number of gallons made up.

WATER METER If a water meter is being used, number of contacts

BLEED METER Ifableed-owatermeterisbeingused,totalnumberofgallon.Ifbleed/pulse=0

bleed pulses is displayed otherwise bleed gallons

VI. Maintenance

Table of contents

Other Advantage Controls Controllers manuals

Advantage Controls

Advantage Controls MegatronXS User manual

Advantage Controls

Advantage Controls 75 Series User manual

Advantage Controls

Advantage Controls MegaTron Operating instructions

Advantage Controls

Advantage Controls MegatronXS Operating instructions

Advantage Controls

Advantage Controls MegaTronMT User manual

Advantage Controls

Advantage Controls 200 Series User manual

Advantage Controls

Advantage Controls MegaTron Series User manual

Advantage Controls

Advantage Controls MegatronXS Quick start guide

Advantage Controls

Advantage Controls MINI-TROL IF User manual

Advantage Controls

Advantage Controls MegaTron User manual