5CR 12 - CR 16 - CR 20 - BA-vers.3.2 gb.21.07.14.docx

1.0.0 EC Declaration for Incorporation

1.1.0 According to 2006/42/EC dated 09. June 2006, Appendix II B VI for

Incorporation of partly completed machinery.

The manufacturer: Afag Automation AG, Fiechtenstrasse 32, CH-4950 Huttwil

Tel. +41 62 959 87 02, www.afag.com

As manufacturer of the partly completed machine we declare that:

-The specified machine corresponds to the listed essential requirements of the

directive 2006/42/EG, where applicable the other directives and standards

listed below.

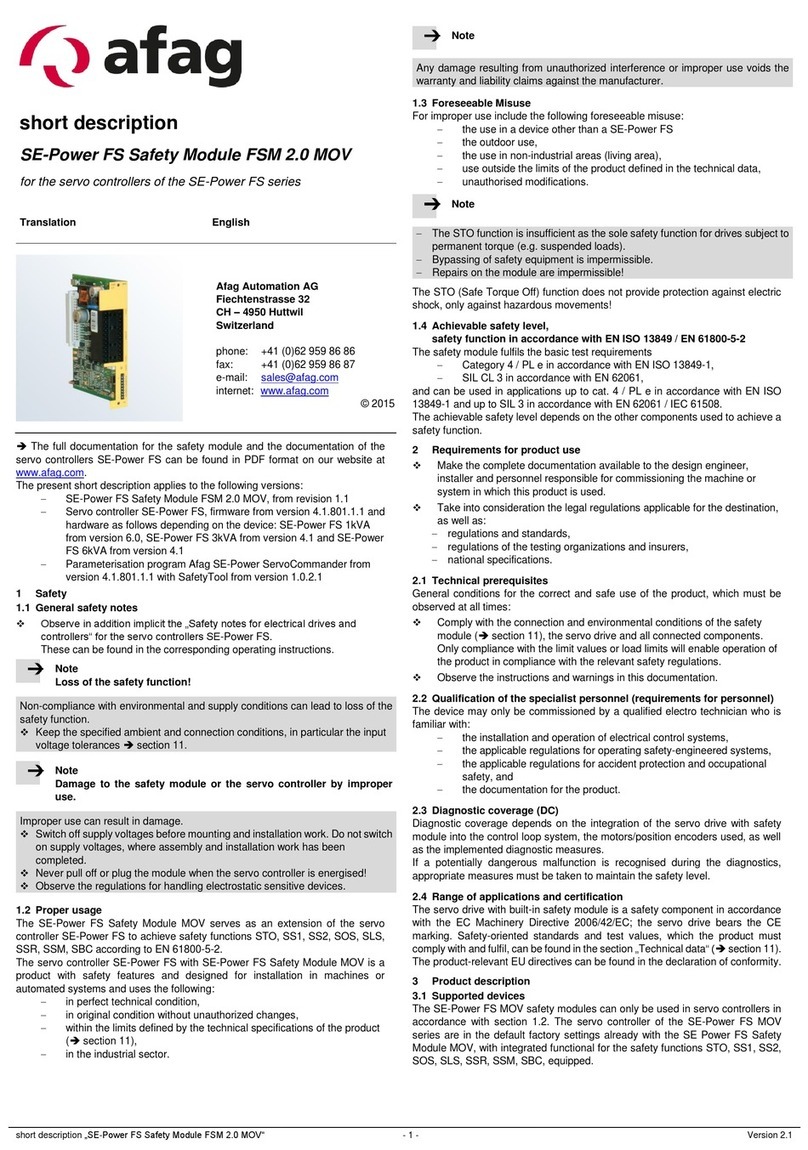

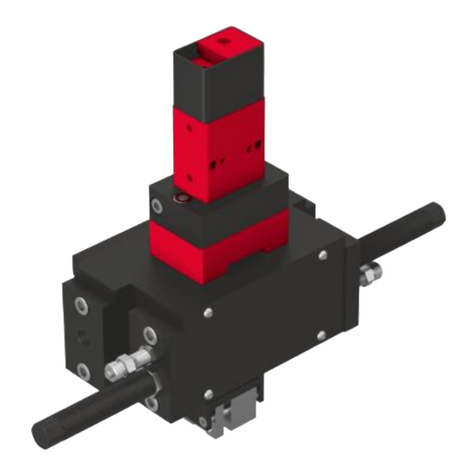

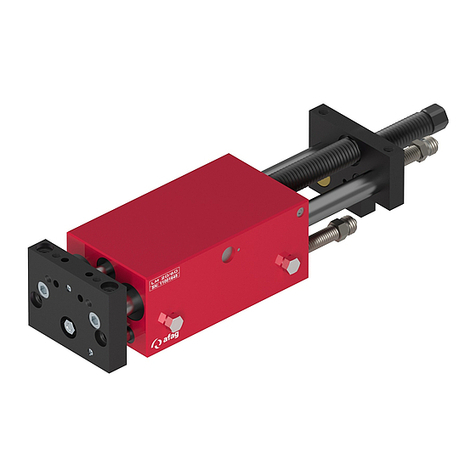

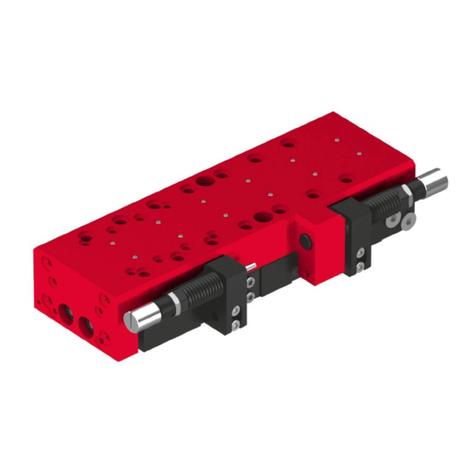

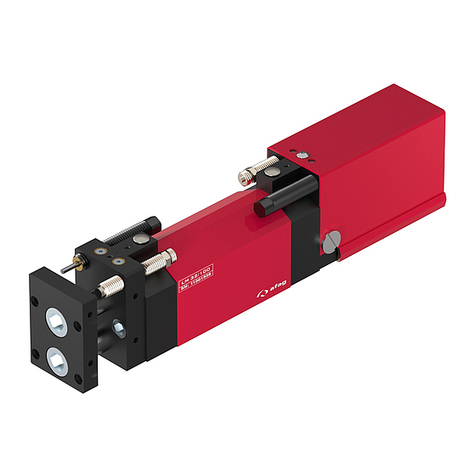

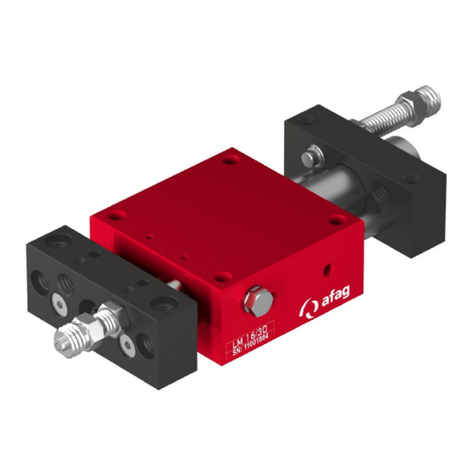

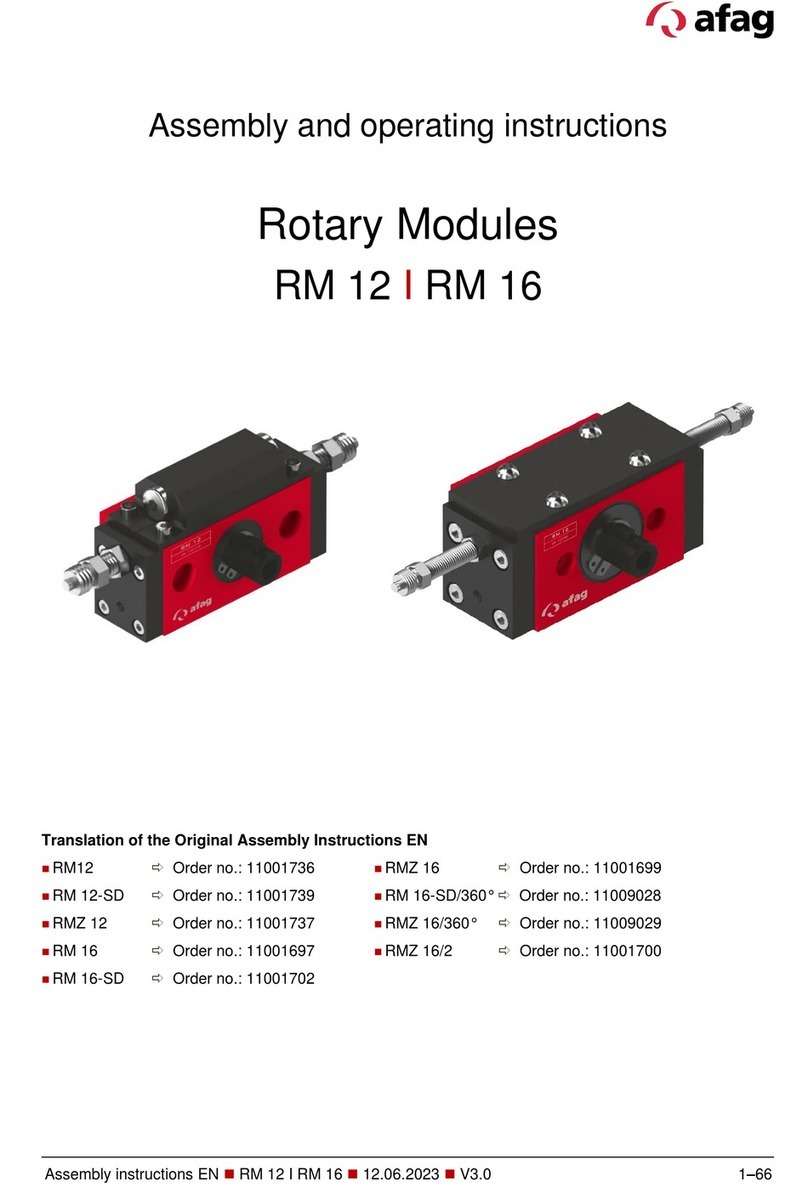

Designation: Rotary module compact (pneumatic)

Type: CR 12 / CR 16 / CR 20

Consecutive serial: Nr.50xxxxxx

Machinery Directive 2006/42/EG

-The relevant technical documentation is compiled in accordance with part B of

Annex VI

-The relevant technical documentation in accordance with part B of Annex VI

will be transmitted in response to a reasonable request by the national

authorities in printed from or in electronic from (pdf).

Applied and fulfilled essential requirements:

-1.1; 1.1.1; 1.1.2; 1.2.3; 1.3.3; 1.3.5; 1.3.6; 1.3.7.1.4.1; 1.5; 1.6; 1.6.1;

1.6.3; 1.6.4; 1.7; 1.7.4; 1.7.4.1; 1.7.4.2

-Increase of the harmonized standards applied:

-EN 349; EN ISO 12100-1; EN 12100-2 partly fulfilled

This partly completed machinery must not be put into service until the final machinery

into which it ist o be incorporated has been declared in conformity with the provisions

of this Directive 2006/42/EC, where appropriate.

Name and address of the person authorised to compile the relevant technical

documentation: Lanz Beat, PM & Marketing-Services, Afag Automation AG

Place, date: Huttwil, 21. Juli 2014

Siegfried Egli Markus Werro

Head of HT Managing Director

Afag Automation AG Afag Automation AG