LE-50-LE-60-LE-70-OI-vers. 2.1 gb. 28.07.14 3

Contents

1.0.0 EC Declaration for Incorporation..........................................................5

2.0.0 Module Information.................................................................................7

2.1.0 Safety.............................................................................................................7

2.1.1 Transport, Handling, Storage .........................................................................7

2.1.2 Module Description.........................................................................................8

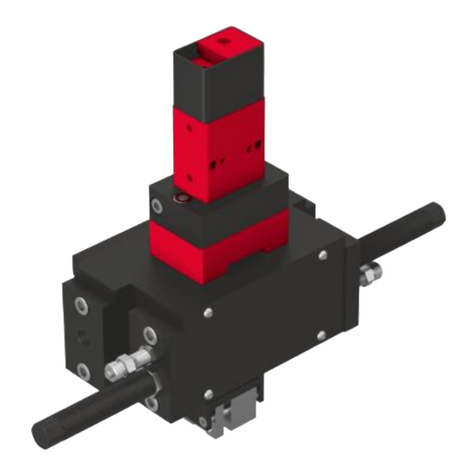

Description of the module types ...................................................................10

2.1.3 Installation, Connection................................................................................11

2.1.4 Installation and mounting options.................................................................12

Tightening moments for bolts .......................................................................13

2.1.5 Installation into a system..............................................................................14

2.1.6 Preferred combinations to LE-50..................................................................16

2.1.7 Preferred combinations to LE-60..................................................................17

2.1.8 Preferred combinations to LE-70..................................................................18

2.1.9 Electrical interfaces (pin assignment)...........................................................19

2.2.0 LE linear programming modules...................................................................20

3.0.0 Montage Instructions............................................................................21

3.1.1 The delivery..................................................................................................22

3.1.2 Intended use.................................................................................................22

3.1.3 Warranty.......................................................................................................23

3.1.4 Safety...........................................................................................................23

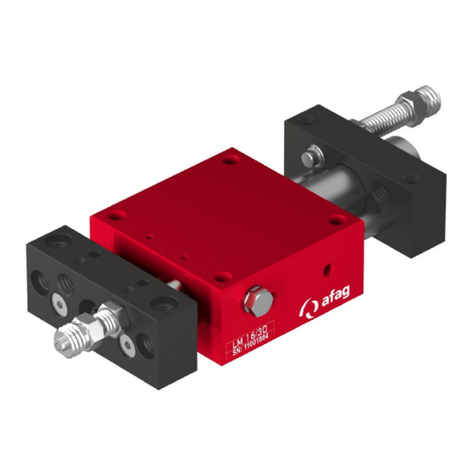

3.1.5 Dimensional drawing LE-50..........................................................................24

3.1.6 Technical data LE-50....................................................................................25

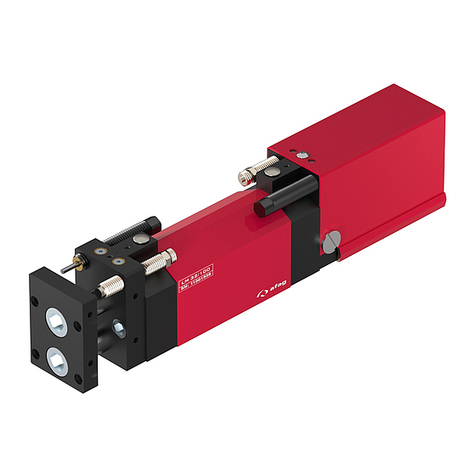

3.1.7 Dimensional drawing LE-60..........................................................................26

3.1.8 Technical data LE-60....................................................................................27

3.1.9 Dimensional drawing LE-70..........................................................................28

3.2.0 Technical data LE-70....................................................................................29

3.2.1 Slide unit load factors LE-50.........................................................................30

3.1.2 Slide unit load factors LE-60.........................................................................31

3.1.3 Slide unit load factors LE-70.........................................................................32

3.1.4 Noise emissions ...........................................................................................33