PG 12-PG 16-PG 20-OI-v.1.2 gb.13.12.12 3

Table of Contents

1.0 Déclaration of incorporation..........................................................................5

2.0 Module Information.........................................................................................6

2.1 Safety instructions.............................................................................................6

2.2 Transport, handling, storage.............................................................................6

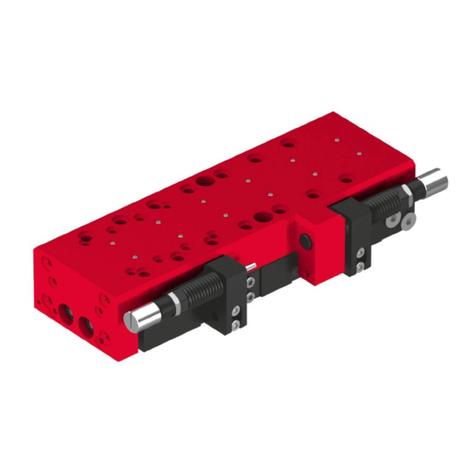

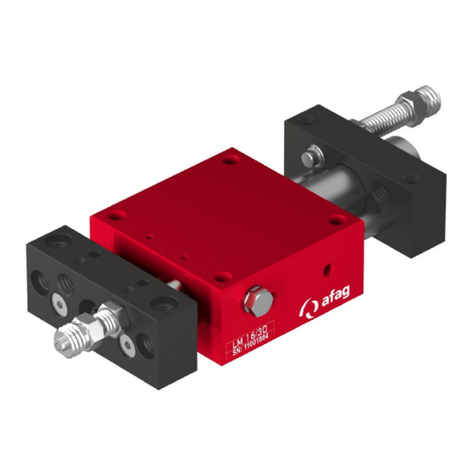

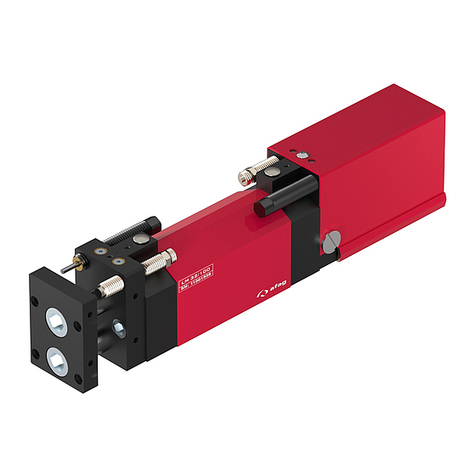

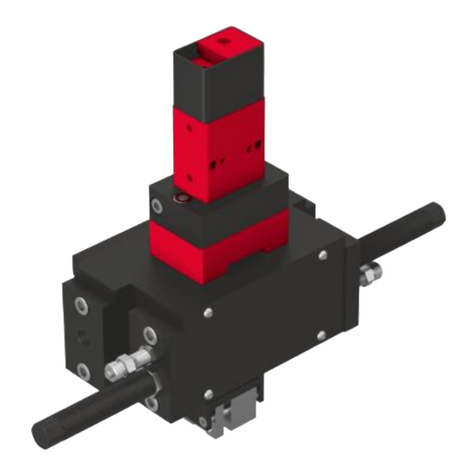

2.3 Description of the module parts........................................................................7

2.4 Parts designation..............................................................................................8

2.5 Mounting, connection........................................................................................8

2.6 Installation and fastening possibilities.............................................................. 9

2.7 Dimensional drawing PG 12 ...........................................................................10

2.8 Technical data PG 12 .....................................................................................11

2.9 Dimensional drawing PG 16 ...........................................................................12

2.10 Technical data PG 16 .....................................................................................13

2.11 Dimensional drawing PG 20 ...........................................................................14

2.12 Technical data PG 20 .....................................................................................15

2.16 Tightening moments for bolts..........................................................................19

2.17 Assembly of the gripper fingers.......................................................................19

2.18 Pneumatic connection.....................................................................................20

3.0 Montage InstructionsFehler! Textmarke nicht definiert. ...............................21

3.2 Intended use...................................................................................................22

3.2 Warranty.........................................................................................................23

3.3 Safety instructions...........................................................................................23

3.6 Start-up...........................................................................................................25

3.7 Adjustment, retrofitting....................................................................................25

3.8 Standard operation .........................................................................................26

4.0 Maintenance Instructions.............................................................................27

4.1 Maintenance and servicing.............................................................................27

Regular maintenance..................................................................................... 27

Further maintenance...................................................................................... 27

4.2 Maintenance...................................................................................................28

4.3 Troubleshooting..............................................................................................29

4.4 Spare parts.....................................................................................................30