GMQ 12 RE-50-OI-vers. 1.2 gb. 28.07.2014 3

Table of Contents

1.0 EC Declaration for Incorporation .......................................................................5

2.0 Module Information.............................................................................................7

2.1 Safety....................................................................................................................7

2.2 Transport, handling, storage .................................................................................7

2.3 Module Description...............................................................................................7

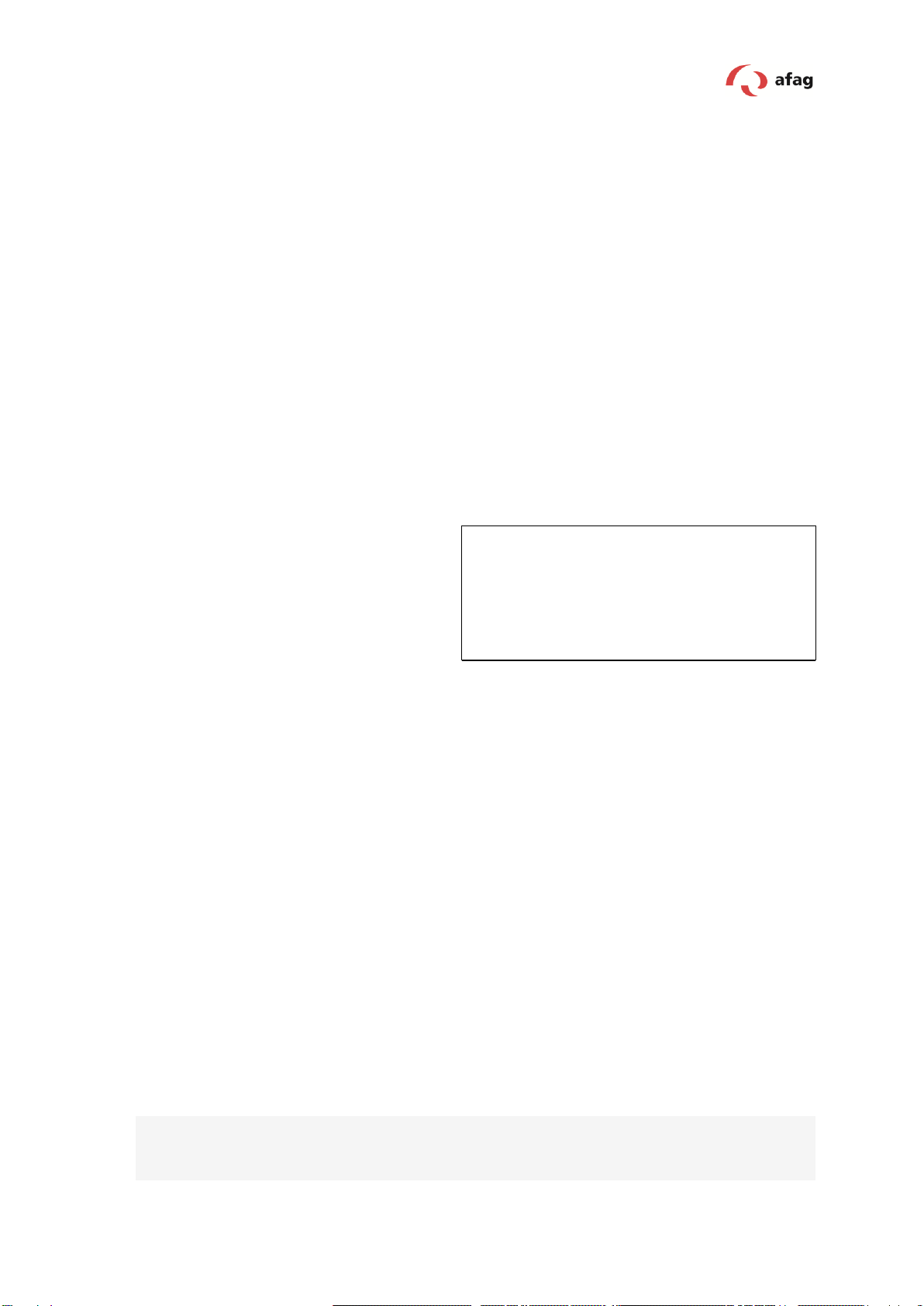

2.4 Nomenclature construction gripper rotary module GMQ 12 / RE-50……………. 8

2.5 GMQ 12 / RE-50 pneumatically /electric……………………………………………..9

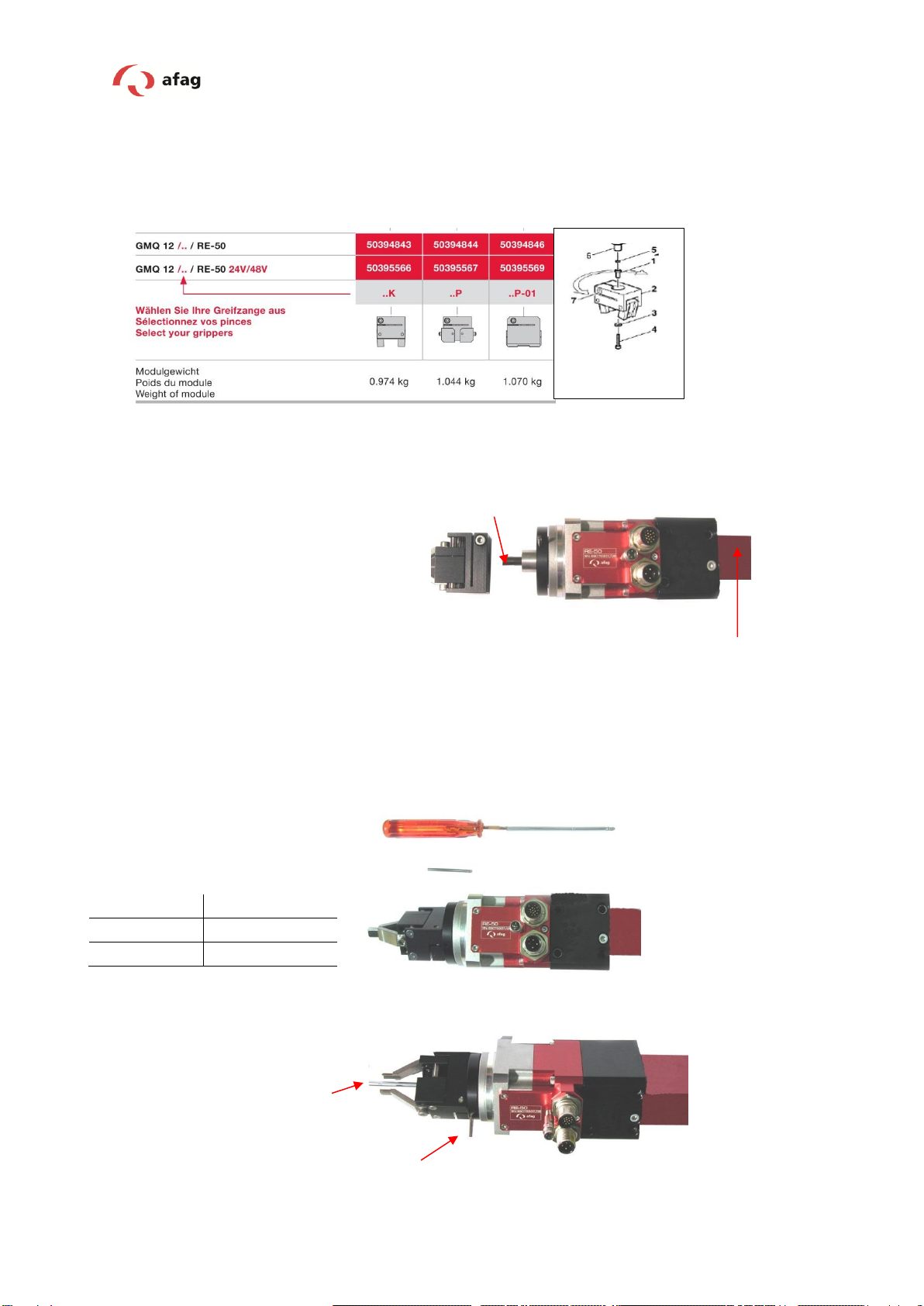

2.6 Mounting of the gripping pliers………………………………………………………10

2.7 The gripper fingers are not included………………………………………………..11

2.8 Assembly connection.........................................................................................11

2.9 Tightening moments for screw.......................................................................... 13

2.10 Installation in a system .....................................................................................14

2.11 Turning the rotary module if the cable outlets don’t fit .....................................15

3.0 Mounting Instructions.....................................................................................17

3.1 Intended use.......................................................................................................18

3.2 Warranty.............................................................................................................19

3.3 Safety .................................................................................................................19

3.4 Dimensional drawing: GMQ 12 / RE-50..............................................................20

3.5 Technical data GMQ 12 / RE-50.........................................................................21

3.6 Graph of gripping forces eccentricity……………………………………………….22

3.7 Rotary modules RE-50 (without flange)………………………………………...…..23

3.8 Rotation time RE-50…………………………………………………………………..24

3.9 Technical data RE-50………………………………………….……………………..26

3.10 Electrical interface ...........................................................................................25

3.11 Commissioning, operation, training ..................................................................26

3.12 Preparation for commissioning .........................................................................27

3.13 Commissioning..................................................................................................28

3.14 Setting / Changeover........................................................................................28

3.15 Normal operation..............................................................................................29

4.0 Maintenance Instructions ................................................................................30

4.1 Servicing.............................................................................................................30