Phone: US 888-215-3966 EU: 44.845.230.7800

www.afinialabel.com

3

Table of Contents

Introduction........................................................................................................................................................5

Using the applicator.......................................................................................................................................5

Included Items................................................................................................................................................6

Specification ..................................................................................................................................................6

Noise information...........................................................................................................................................6

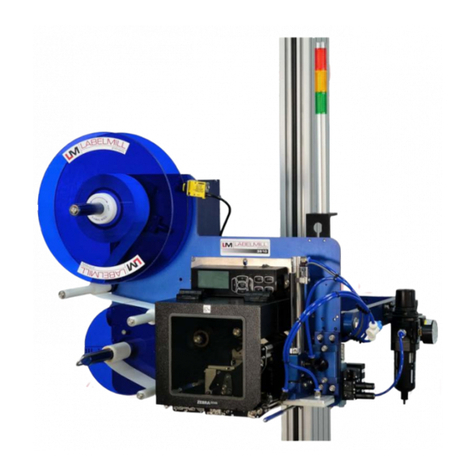

Equipment Description...................................................................................................................................6

General safety instructions ................................................................................................................................8

Workplace Environment.................................................................................................................................8

Specific safety instructions.............................................................................................................................8

Operating instructions........................................................................................................................................9

Setup.............................................................................................................................................................9

Preparing the applicator.................................................................................................................................9

Turning on the applicator .............................................................................................................................11

How to determine the Offset Stop value.......................................................................................................11

Working with the menu and changing parameters........................................................................................12

Labeling.......................................................................................................................................................12

Adjusting display contrast and brightness ....................................................................................................12

Adjustment of the label sensor.....................................................................................................................13

How to determine the Offset Stop value.......................................................................................................14

How to determine the Offset Stop 1 value....................................................................................................15

How to determine the Offset Stop 2 value....................................................................................................16

Memory Locations........................................................................................................................................17

Working with the menu and changing parameters........................................................................................17

ONE LABEL mode parameters.................................................................................................................18

TWO LABEL mode parameters................................................................................................................19

How to determine the distance between labels ............................................................................................20

Maintenance and cleaning...............................................................................................................................21

Service............................................................................................................................................................21

Transportation.................................................................................................................................................21

Warranty..........................................................................................................................................................22

Regulatory Details...........................................................................................................................................23

Technical Support............................................................................................................................................24