-2 -

Content

1. Introduction ...................................................................................................

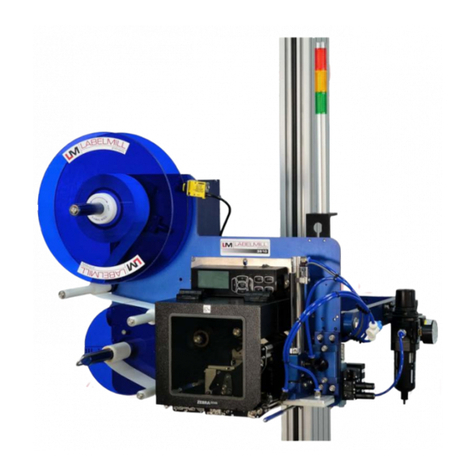

Applicator Operation .....................................................................................page 4

Description .................................................................................................. page 5

Scope of delivery ........................................................................................page 5

Technical data ............................................................................................ page 5

Noise information ........................................................................................page 6

2. General safety instructions for handling electrical appliances.

Safe work ................................................................................................... page 7

Specific safety instructions .........................................................................page 7

3. Operating instructions.

Installation.....................................................................................................page 8

Power on .................................................................................................... page 8

Setting Offset start’ ....................................................................................page 8

Setting ‘Offset stop’ .................................................................................... page 8

Loading labels and calibrating the label sensor ......................................... page 9

Positioning of the bag .................................................................................page 9

Working with the menu and changing parameters .....................................page 9

Verify settings...............................................................................................page 9

Labeling ......................................................................................................page 10

Errors ..........................................................................................................page 10

Service menus ............................................................................................page 10

Adjusting of the display .............................................................................. page 10

4. Offset start ....................................................................................................page 11

5. Offset stop - mode 1 label ........................................................................... page 12

6. Offset stop 1, Offset stop 2 - mode 2 labels .............................................. page 13

7. Loading labels ..............................................................................................page 15

8.

Calibrating up the label sensor .................................................................. page 16

9. Working with the menu and changing parameters ...................................page 17

10.

Working with the service menu and changing parameters .....................page 19

11.

Errors and actions. ......................................................................................page 21

12.

Adjust the brightness and contrast of the display ...................,,,.............page 22

13.

Service menu - counters .............................................................................page 23

14.

Service menu - inputs ..................................................................................page 23

15.

Maintenance and cleaning ..........................................................................page 24

16.

Service ..........................................................................................................page 24

17. Warranty

General terms ............................................................................................page 25

Warranty conditions ....................................................................................page 25

18.

Transportation ................................................................................................page 25

19.

Disposal .......................................................................................................... page 25

20.

Contact Support ...............................................................................................page 26

page 3

V.2.01

www.afinialabel.com