August 2023

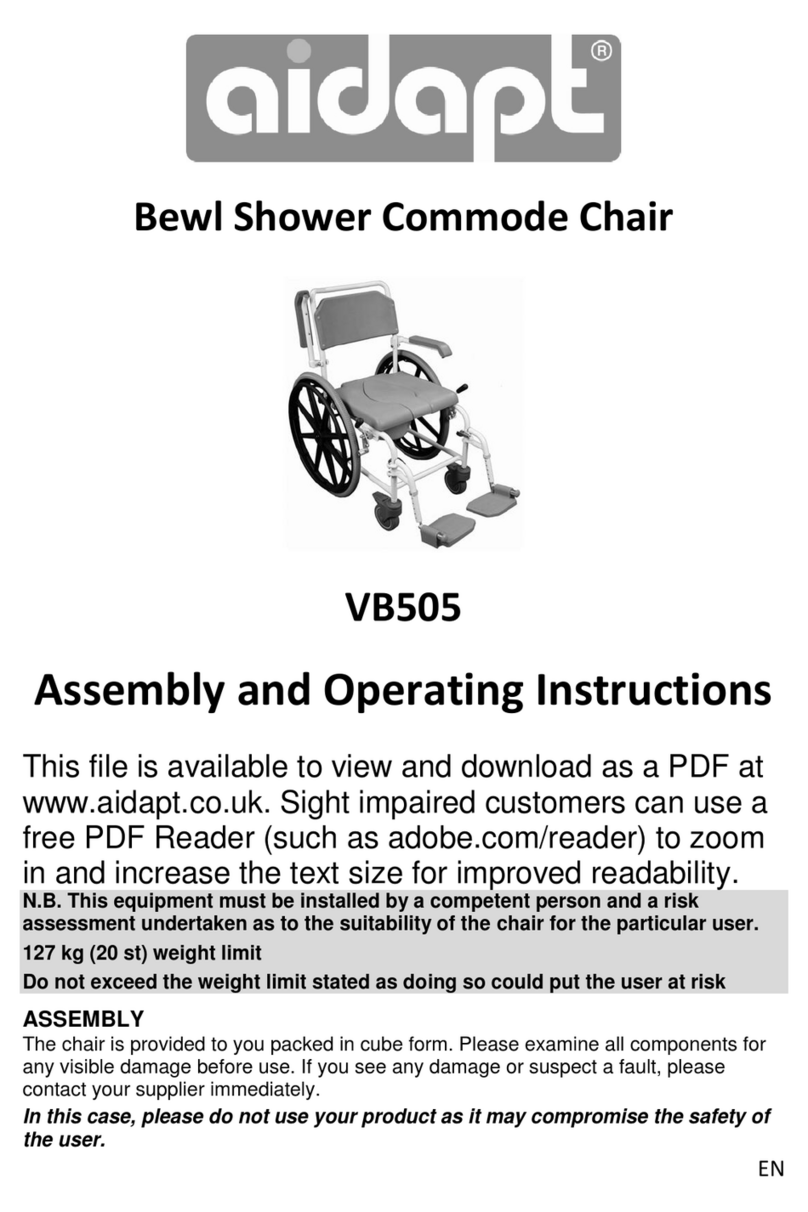

1. Push Handles

The handles are designed for the helper to propel the chair. They must not be used solely

for lifting the chair over obstructions or kerbs (see negotiating obstacles) The helper

should not place all of their weight on the handles by lifting their feet o the oor

as this will place adverse strain on the handles.

2. Backrest Upholstery

Periodically check the upholstery for signs of tears or sagging. Replace immediately if the

seat is damaged

3. Armrest Release Lever

Push the lever to release the armrests from the socket to allow them to be ipped up.

4. Leg Rest Release Lever

Press the release lever towards you and swing the support to the outside of the chair. If the

support is to be removed, lift it upwards. To re-t and return to the original position, reverse

the above procedure.

5. Footrest Adjustment Bolt

The footplates are intended as a foot support only when you are sitting in the chair. On

no account should you stand on the footplates. The heel loops or calf straps (if tted) can

be used to secure the position of the feet. The footplate assemblies can be adjusted in

height by loosening the nut of the base of the adjustment tube, positioning the plate at the

required height and tightening the nut to secure the assembly.

The footplates are detachable and may be swung away from the chair and also removed. To

remove the footplates from the frame, release the leg rest release lever and lift the footplate

6. Adjustable Brake

These are used to hold the chair in a stationary position, and are tted on either side of the

chair. They should not be used when the chair is moving or to slow it down. They should

always be applied together.

To operate, push the brake lever forward towards the front of the chair. This will immobilize

the chair. To release the brake, move the lever towards the rear of the chair.

7. Castors & Bearings

The front wheels have solid puncture proof tyres. These should be checked at regular

intervals to monitor any wear. Transit chairs become dicult to steer and propel when

surfaces have worn at. It is recommended that both front tyres are replaced at the same

time to avoid one side of the chair from being higher than the other.

The wheel is secured to the castor fork by an axle bolt and axle nut. Periodically, this bolt

and nut should be checked and tightened if necessary to allow a snug but free spinning

t. The castor fork swivel allows the chair to be steered. An adjustment locknut is located

under the castor cap. If the locknut is too tight, the chair will be dicult to steer.