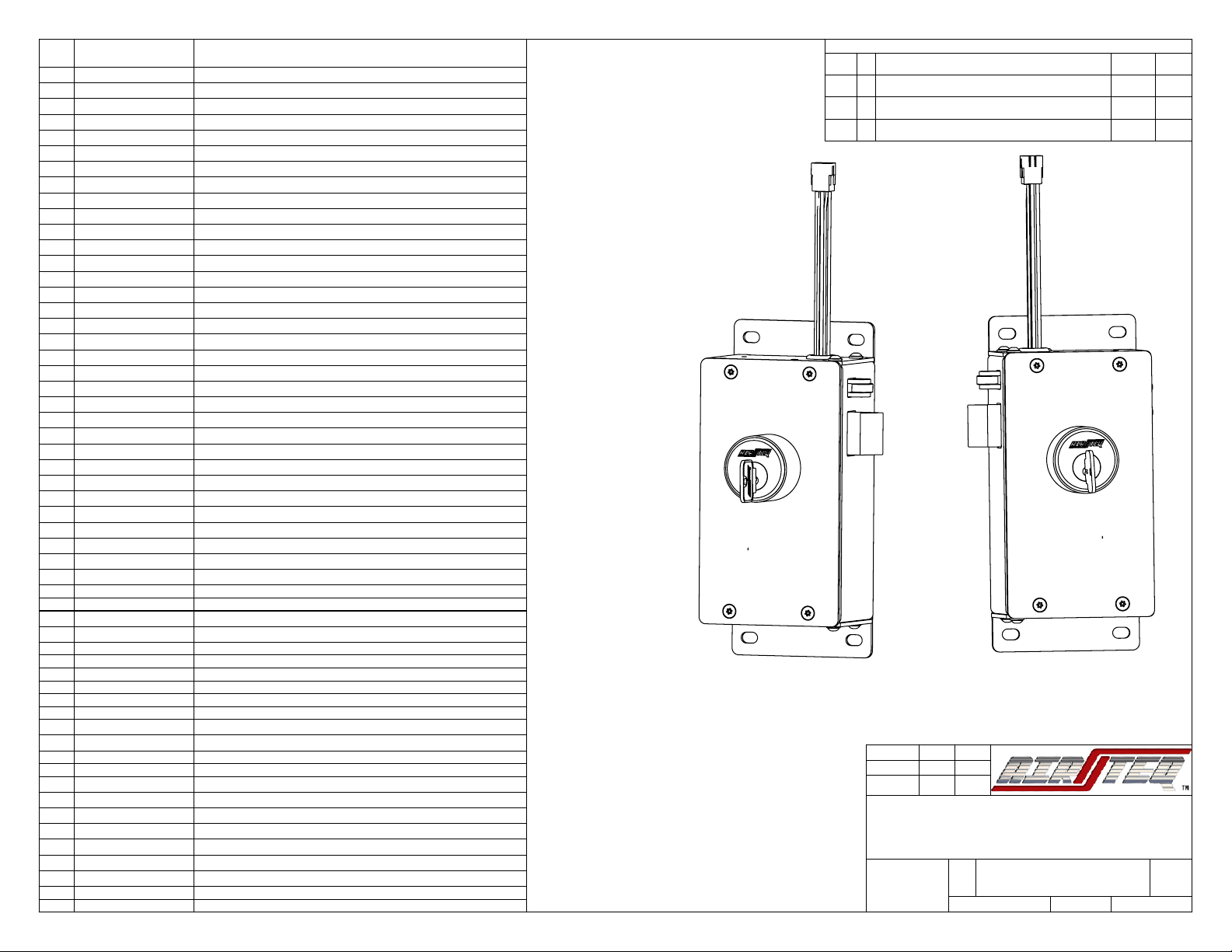

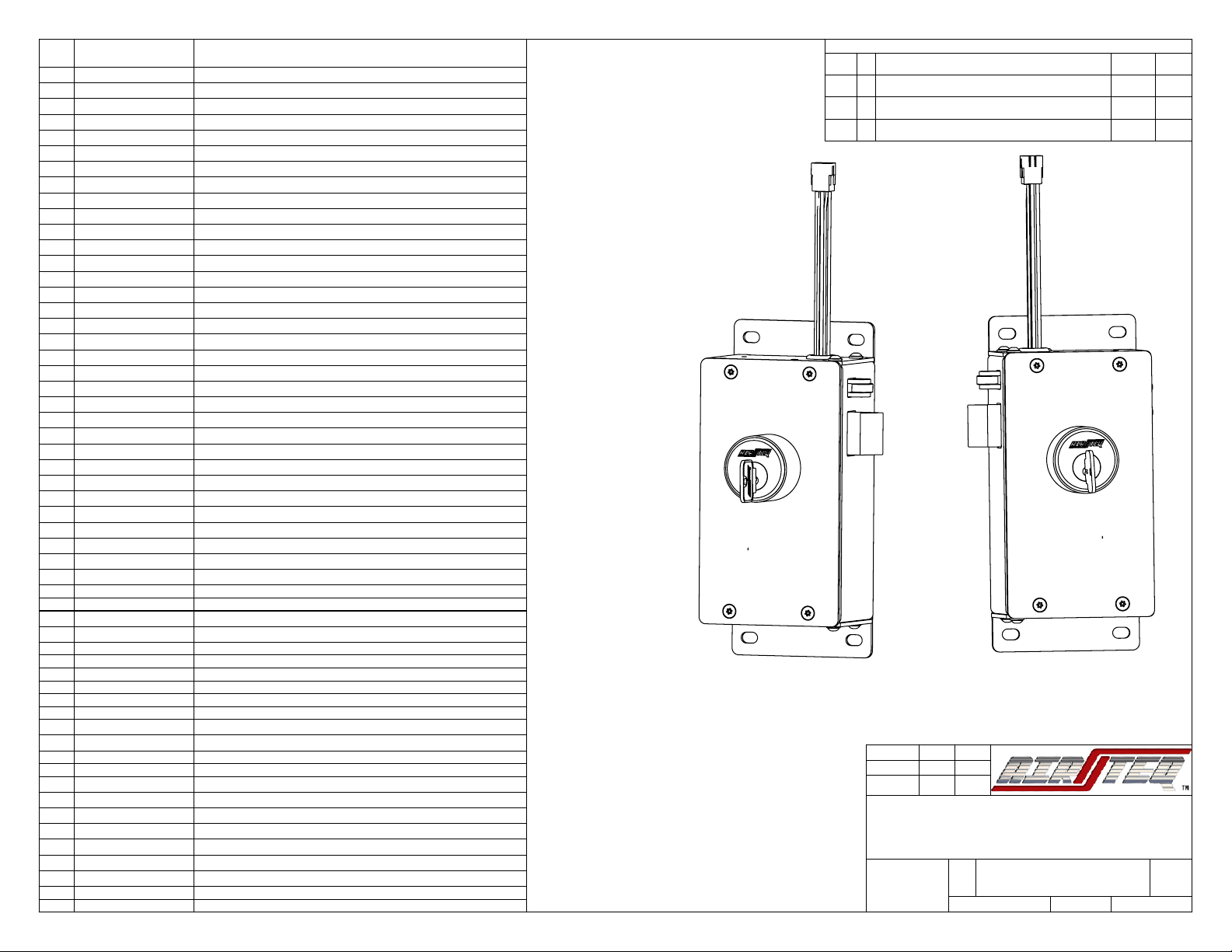

9900 Series Lock LH

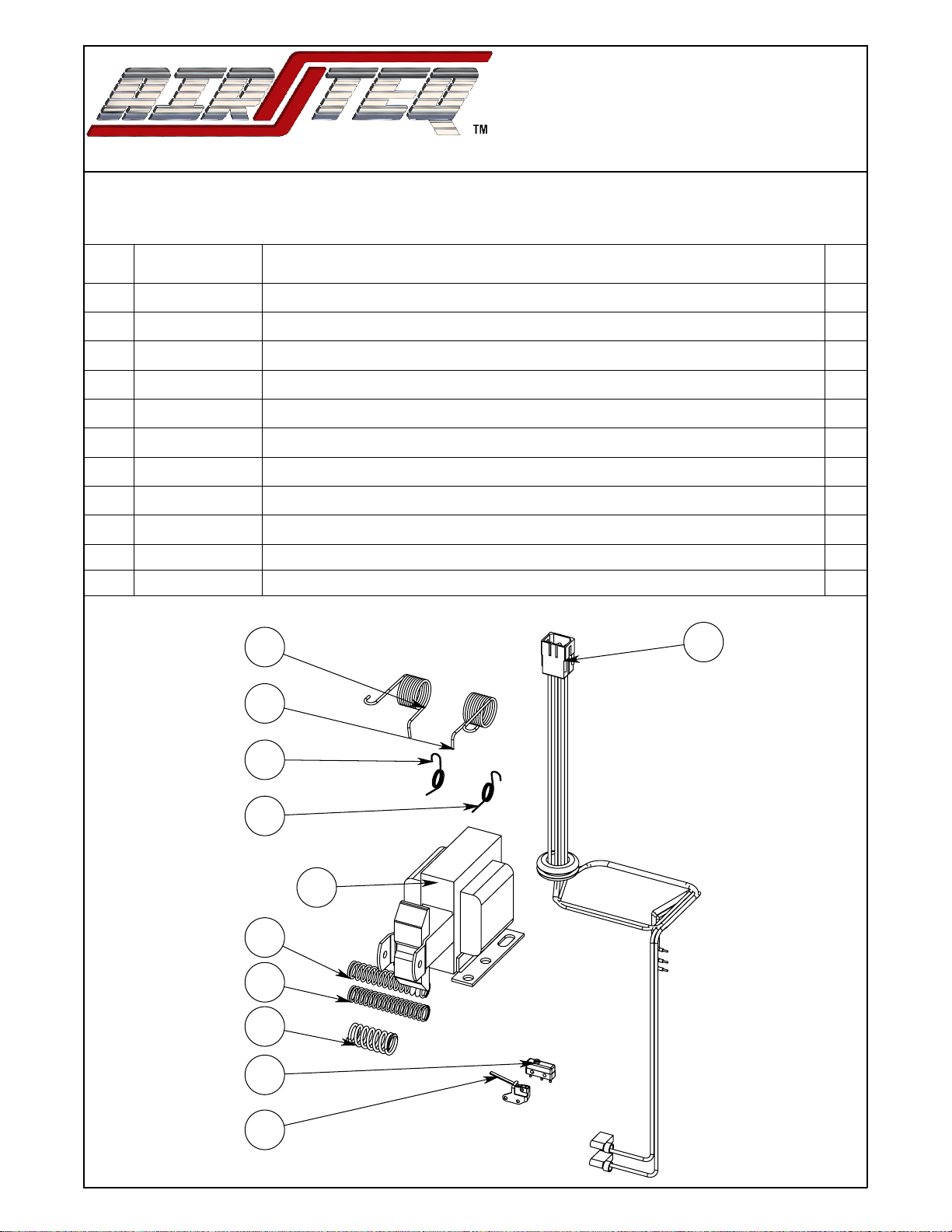

NOTES:

1. 146-9900-126L may be substituted for 146-9900-125L in left

hand motor locks

2. 146-9900-126R may be substitued for 146-9900-125R in

right hand motor locks

3. Same length button head cap screws may be used in place

of hex head cap screws to mount motor/solenoid assemblies to

lock body. Specifically item numbers 36 (used to mount

solenoid assemblies) and 37 (used to mount motor assemblies)

9900 Series Lock RH

ITEM

NO.

PART NUMBER

DESCRIPTION

1 10002511

Shoulder Screw Ø3/8"x1 1/4", 5/16-18 Nylock

2 10002513

Shoulder Screw Ø3/8"x3/8", 5/16-18 Nylock

3 10003203

Spring Anchor, 7/8in, 8-32x5/8 Thread, Black Oxide

4 10003204

Hook End Ext. Spring, .375"OD, 2.5"Length

5

146-9900-107L

Actuator Assembly, Left Hand

6

146-9900-107R

Actuator Assembly, Right Hand

7

146-9900-107SL

Solenoid Lock Actuator Assembly, Left Hand

8

146-9900-107SR

Solenoid Lock Actuator Assembly, Right Hand

9

146-9900-122

Latchbolt Assembly

10

146-9900-124L

Left Hand Deadlatch Assembly

11

146-9900-124R

Right Hand Deadlatch Assembly

12

146-9900-125L

Deadlatch Catch Indication Assembly, LH

13

146-9900-125R

Deadlatch Catch Indication Assembly, RH

14

146-9900-126L

Deadlatch Pivot / Lock Status Switch Mount Assembly, LH

15

146-9900-126R

Deadlatch Pivot / Lock Status Switch Mount Assembly, RH

16

146-9900-272

9900 Key Switch Assembly, Keyed Two Sides

17

146-9912M-100L

9900 120VAC Left Hand Motor Assembly

*17*

146-9912M-100L-HC

Half Cycle, 9900 120VAC Left Hand Motor Assembly

18

146-9912M-100R

9900 120VAC Right Hand Motor Assembly

*18*

146-9912M-100R-HC

Half Cycle, 9900 120VAC Right Hand Motor Assembly

19

146-9912S-100

9900 120VAC Solenoid Assembly

20

146-9924M-100L

9900 24VDC Left Hand Motor Assembly

*20*

146-9924-100L-HC

Half Cycle, 9900 24VDC Left Hand Motor Assembly

21

146-9924M-100R

9900 24VDC Right Hand Motor Assembly

*21*

146-9924-100R-HC

Half Cycle, 9900 24VDC Right Hand Motor Assembly

22

150-9900-110L

Side Housing Weldment, Left Hand Lock

23

150-9900-110R

Side Housing Weldment, Right Hand Lock

24

160-9912M-100

9912M Main Wiring Harness

25

160-9912S-100

9912S Main Wiring Harness

26

160-9924-100

9924 Main Wiring Harness

27

216-1000-028

Mogul Cylinder, SPANNER Lock NUT

28

216-9900-100

Main Housing Back

29

216-9900-102

Back Mounting Plate Keyed Back Side

30

216-9900-105

Cover Plate

31

216-9900-217

Deadlatch Cushion

32

216-9900-220L

Spring Support Base, LH

33

216-9900-220R

Spring Support Base, RH

34

216-9900-255

RLB Arm

35

310-2520-001

BOLT, HEX HD, 1/4-20 X .62 LG, STL, PLATED

36

310-2520-004

BOLT, HEX, HD, 1/4-20 X .38 LG., STL, PLATED

37

310-2520-045

Screw, BHCS, 1/4-20 X 3/8, Black Oxide

38

310-3100-000

Shoulder Screw, Ø5/16"x3/8, 1/4-20x7/16

39

311-2520-082

Screw, FH,Pin TORX, 1/4-20x1/2, Stainless Steel, UC Head

40

312-3118-004

Thin "Jam" 5/16-18 Nylock nut. McMaster 94945A213 or eq.

41

313-3100-005

5/16in D Washer McMaster 96025A167 or Eq.

41

313-0000-003

WSHR, LOCK, SPLIT, 1/4, STL, PLTD

43

313-0000-120

Fender Washer

44

315-9900-001

Spring, .485"OD x 2.25" Length

45

315-9900-002

Spring, .405"OD x 2.25" Length

46

315-9900-005

.60"ODx1.25"length

47

315-9900-010

RLB Catch, Left Hand Torsion Spring

48

315-9900-011

RLB Catch, Right Hand Torsion Spring

49

315-9900-021

Actuator 360° Right Hand Torsion Spring

50

315-9900-022

Actuator 360° Left Hand Torsion Spring

51

340-0000-170

Anchor Mount Cable Tie Holder

52

340-0000-204

Cable Tie, 4in

REVISIONS

C

B

1/25/18

Added Half Cycle Part Numbers, 216-9900-205 Now Part

of Motor Assemblies

10/27/15

Cumulative: Hex Head motor/sol. mounting screws, add 313-0000-

120, add 216-9900-217 for Sol. locks, etc.

11/17/14

Initial Release

C

ECN #

11/17/14

RLP

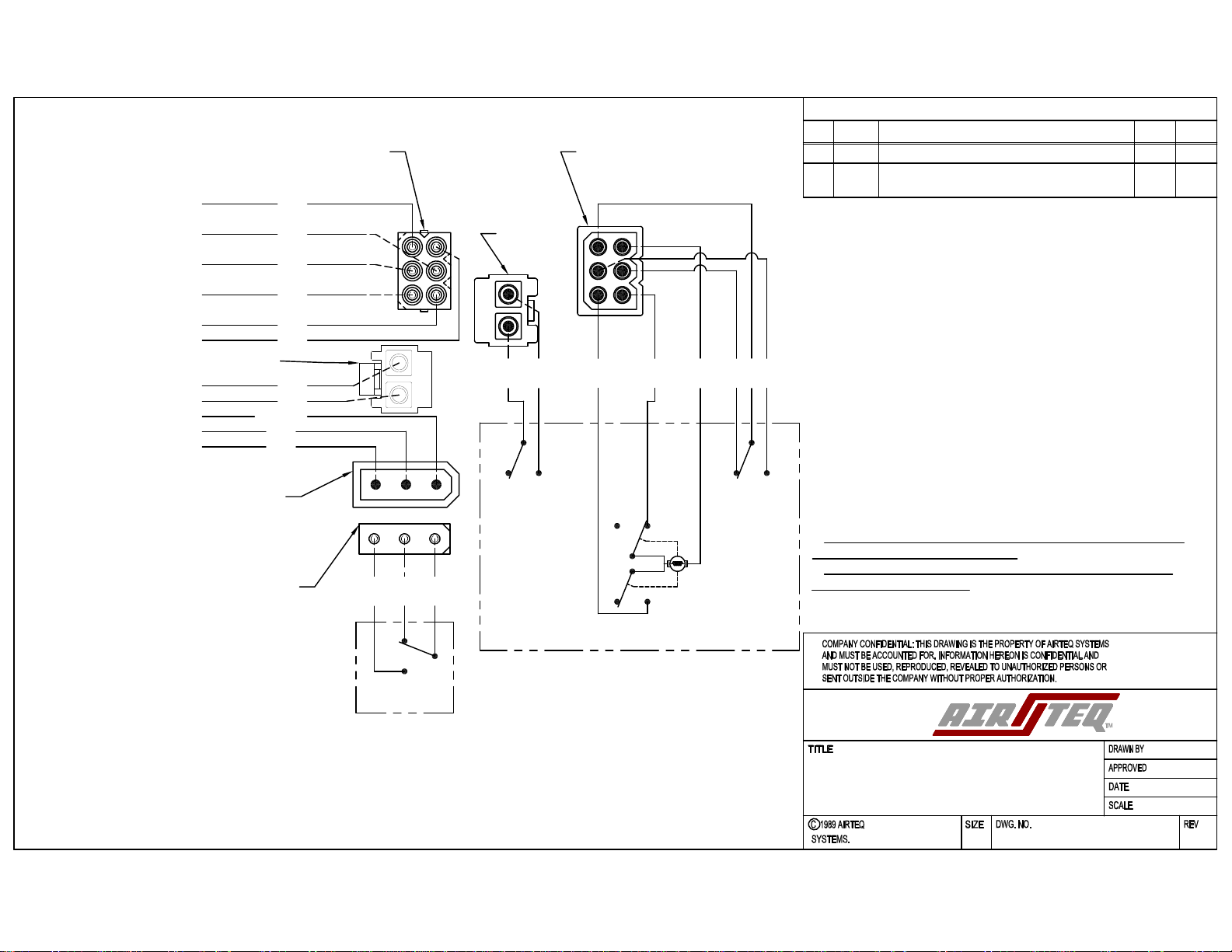

9900 Series 120VAC/24VDC Motor

& 120VAC Solenoid Lock

9912M / 9924M / 9912S

APPROV.

DATE

DESCRIPTION

REV.

SCALE: 1:4

SHEET 1 OF 7

REV

DWG. NO.

A

SIZE

TITLE:

NAME

DATE

CHECKED

DRAWN

FINISH:

A