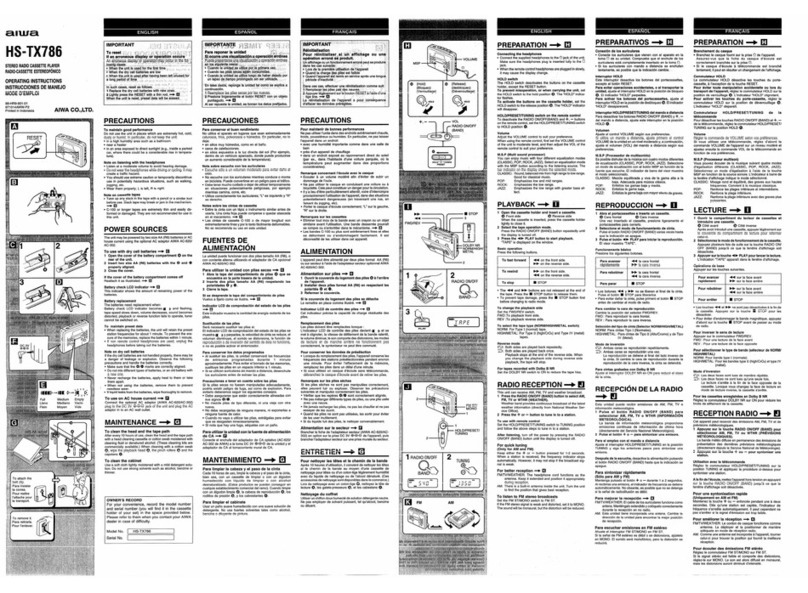

ADJUSTMENT

FXMAIN

C.B

TP2

(DOLBY

OUT

Rch)

w-—TPI

(

DOLBY

OUT

Lech)

HOLE

OF

TAPE

SPEED

ADJ.

@

F-PAC—

KMS

Be

FAKF—-T:TTA-111S

FR

FWDKRCT-TFAEC—KA,

300

OWI

RSR

KSFRIL&EMBTS.

RRECERHO+4

SCHOLL

EHTS.

@

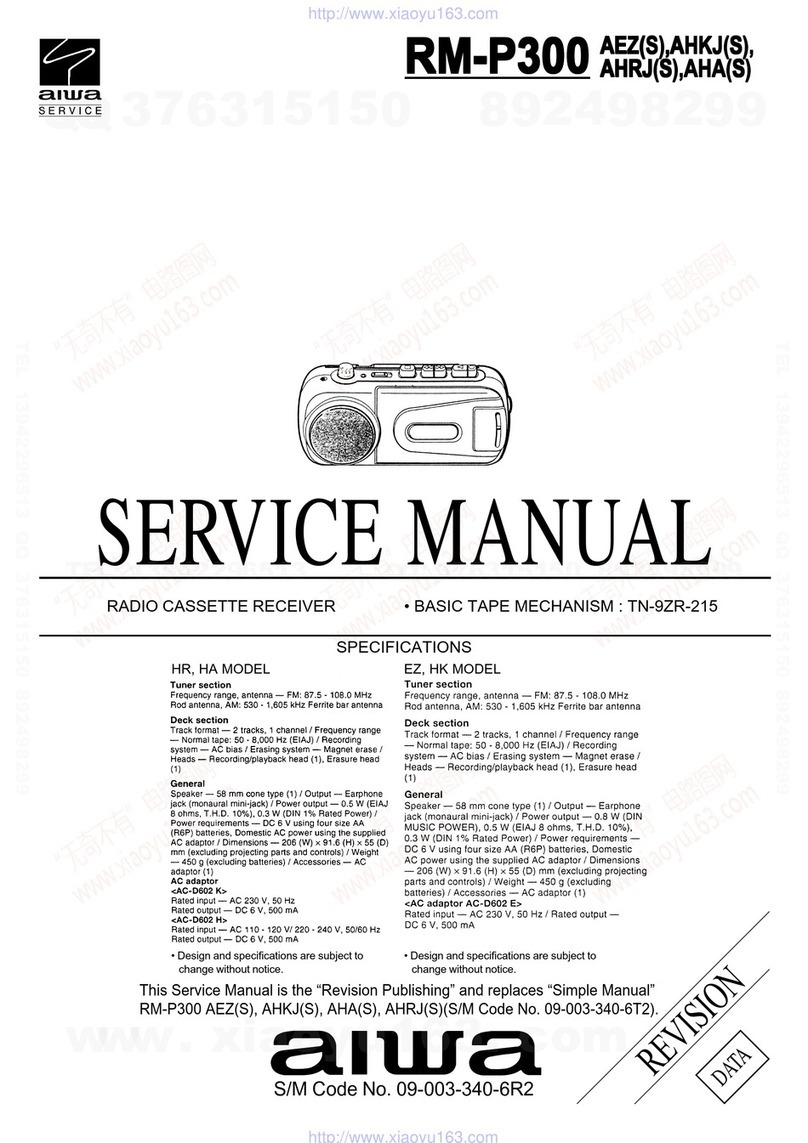

Tape

Speed

Adjustment

Setting

:

Test

tape

TTA-111S

Method

:

Adjust

SFR1

so

that

the

tape

speed

is

3000Hz

in

the

FWD

mode.

Confirm

the

tape

speed

is

within

+45Hz

relative

to

the

forward

direction

when

a

tape

runs

in

the

reverse

direction.

@

YVrARS

AvP

FARF—-PF:TCC—152(TTA-113B)

BR

VVVARBRY

@

Azimuth

Adjustment

Setting

:

Test

tape

TCC-

152(TTA-113B)

Method

:

Azimuth

adjusting

screw.

HMOTORC.B

@

KIVeE-VAILIRS

BEE

FART

a

oe

shite

care

Sica

pe

Me

TCC-130(TTA-161)

IRI

IC

HT

L

TO

ERIE

ee

er

ee

a

eingiet

ds,

teapots

FWD

play

7T-TSW...

ee

tee

FOV

CURRENT

CHANGE

WITH

SLITS

DOLBY

NR

ocad

gee

bOFF

©.

©

AND

@

SET

10

OPEN

Oe

eee

DSS

Wie.

Seticue

Gees

..

OFF

Ft

FARRAH

YA

TP1(Lch),

TP2(Rc

h)

Of

MLOOmVtSmMVERSESIKSFRI(Lch)

SFR2(Rch)

CHESS.

@

Dolby

Level

Adjustment

Setting

:

Test

tape..........c.005

TCC-130

(TTA-161)

Mode.

.ccccecccccceveccosl

WD

play

Tape

SW.........-2200-

.

Normal

Dolby

NR...

cee

c

ce

ccecee

OFF

VOLUME...

2...

000s

oeeeeeMin.

DSL

SW..........

Secielsieie

OFF

Method

:

Adjust

SFR1(Lch)

and

SFR2(Rch)

so

that

the

value

at

TPl

and

TP2

is

100mV+oOmV.

®@

Jay,

7AS

BHR

FARRAVYE(TP

3)

OM.

3200+50HK

RWAKIAKSFRIEMBTA.

@®

Clock

Adjustment

Adjust

SFR3

so

that

the

value

at

TP3

is

3200+50Hz.

TE:

—

At

WS

PSN

OD

7.

E-SRERMLEBR.

ROMBADETT.

DAVYUYIRMOKIKAYVYA—,

BHU.

BALRRLET.

HE)

COMPILES

LANTBREBRL.

Vy

hKMAAD

RWKAVETS,

(1)

SFRIXEIL,

245Hzt

2c

week

3HBLET.

(2)

FRCE-—ARMKRL.

FORE

HA250mA+

L0MATH

SX

LRMBLET.

DL.

BRHMOHRKASRVBAI.

R-—1LKHEW

AVY

»y

KO~

OCHBLET,.

(3)

ZOR.

BAMOBRM2mAF

CHS

OL

RHBLET.

(4)

BHRO

+

i+

XDIRECTIONICHEREL.

ESR

RRA

(2),

(3)

XREBLET.

(5)

PRB

LL.

VICLIE,

REIKI

(3)

KROCLE

BLET.

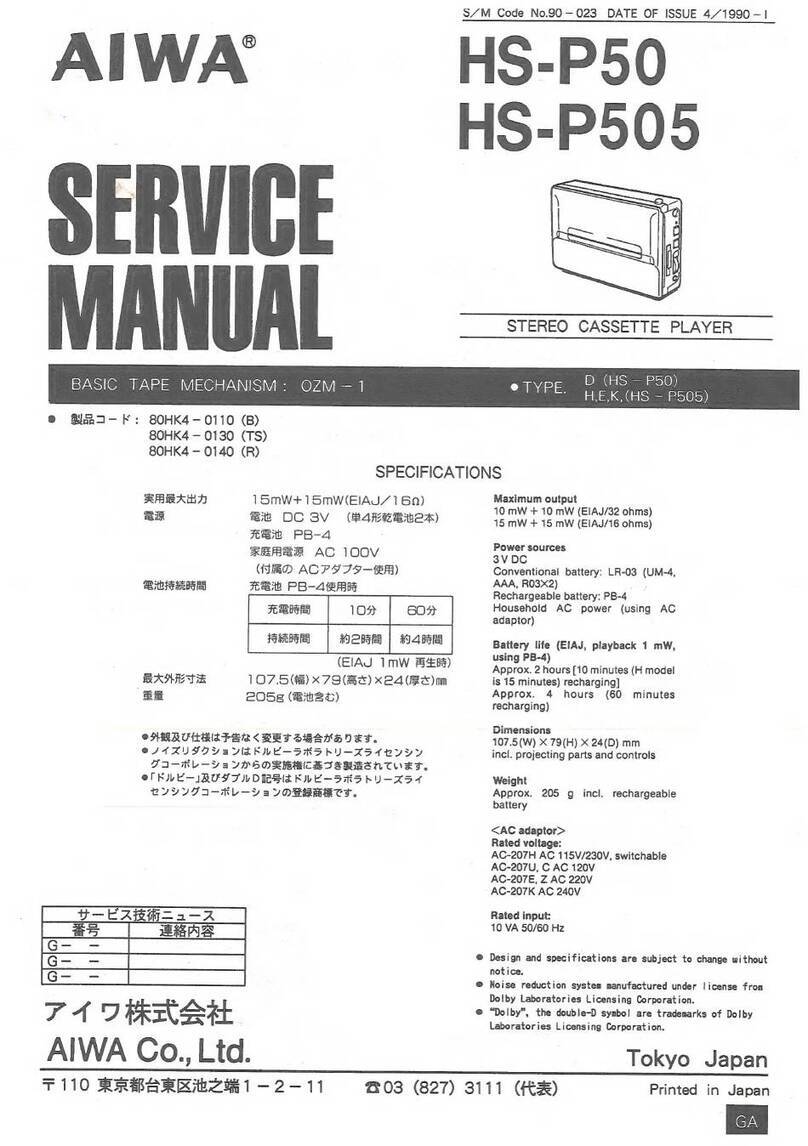

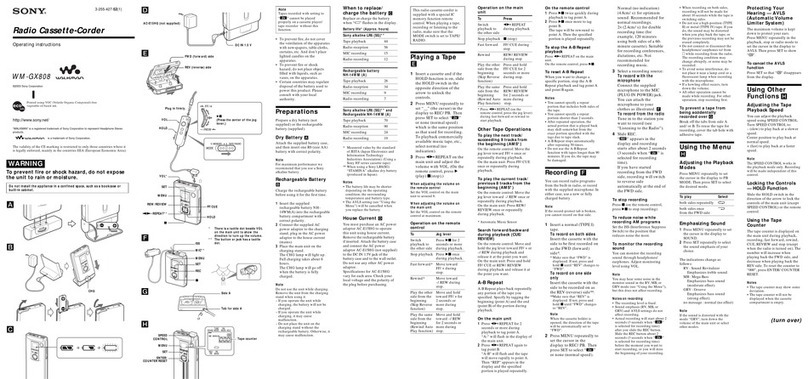

NOTE

ON

REPLACING

THE

MOTOR

The

following

adjustment

should

be

made

after

replacing

a

notor.

As

shown

in

the

wiring

diagram,

connect

the

counter,

ampere

and

power

supply.

NOTE)

Perform

this

adjustment

by

connecting

the

motor

and

governor

circuit

board

before

mounting

them

into

the

unit.

(1)

Adjust

SFR1

to

be

245Hz+2Hz.

(2)

Restrain

the

motor

manually

and

check

that

the

resultant

current

is

250mA+10mA.

If

the

current

reading

does

not

satisfy

the

specification,

adjust

it

according

using

slits

(1)-(3)

according

to

Table

1.

(3)

Check

that

the

unload

current

is

20mA

or

less.

(4)

Connect

the

plus

(+)

pin

of

power

supply

to

the

DIRECTION

terminal

to

rotate

the

motor

in

reverse

and

check

Steps

(2)

and

(3).

(5)

Check

that

Step

(3)

is

satisfied

when

the

motor

is

rotated

in

the

forward

or

reverse

direction

at

a

supply

voltage

of

1.7V.

R-1/Table

1

AUYXbhO,

@.

OM

TOPEND

roe]

5a

oe

Wel

SS

THE

LEA

El

DTIDIVR—

>

0.4534

(RMS)

CVF

u—FHEAH

:

175+

15¢

AU

KIVD

235°)

g-com

(FWD,

REV)

AKU

hI

290

523

g-om

HRL

bIVD

:

110+

25g-cn

SNK

:

50+3dB

BE

2

1.2305

JA

KVR

21.6+1.0nV

(VOL

MAX)

AY

y

BNO.

SLITS

NO.

PRACTICAL

SERVICE

FIGURE

Wow

&

Flatter

:

Less

than

0.45%

(RMS)

Pinch

roller

pressure

:

175+

15g

235

113

g-cm

(FWD,

REV)

FF

torque

290°

g-cm

3

110+

25g-aa

Signal

noise

ratio

>

50+3dB

Take

up

torque

Rewind

torque

Distortion

:

Less

than

1.2%

Noise

level

2

1.641.0mV

(VOL

MAX)